Multi-cylinder hermetic compressor

A hermetically sealed compressor technology, which is applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as inability to effectively set flow paths, and achieve the effects of preventing increase, preventing pressure loss, and improving compressor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0033] Embodiments of the present invention will be described below.

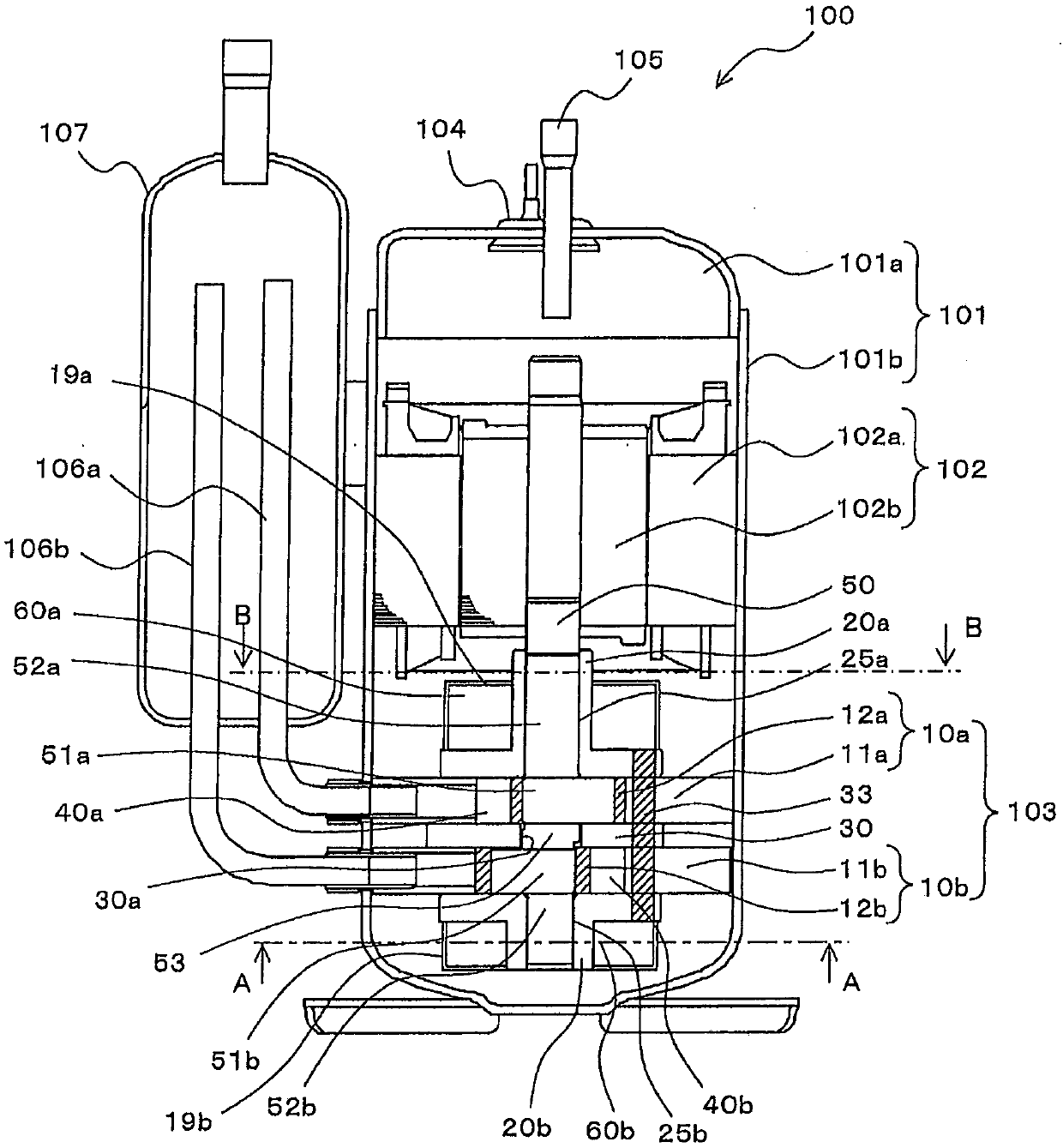

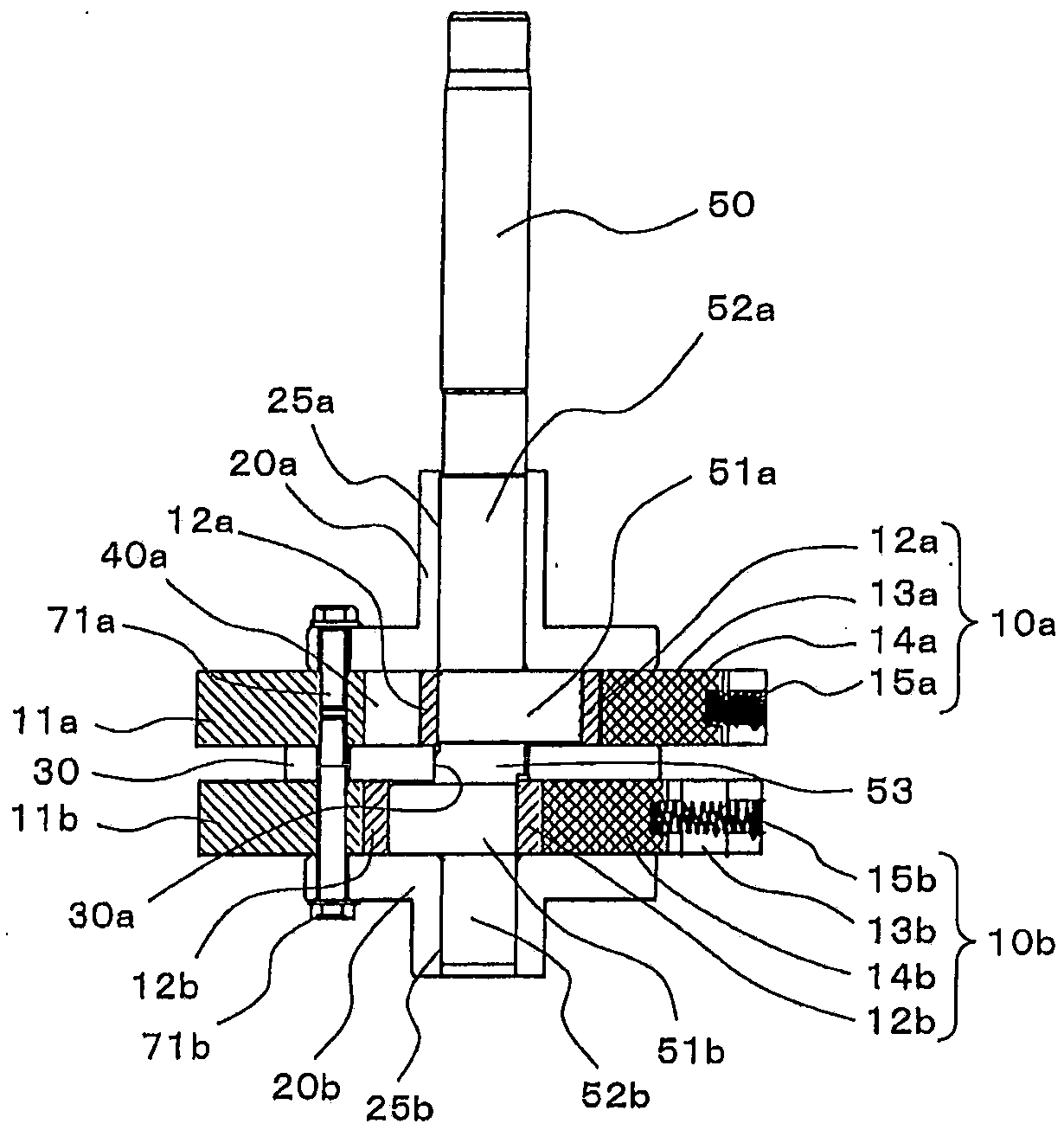

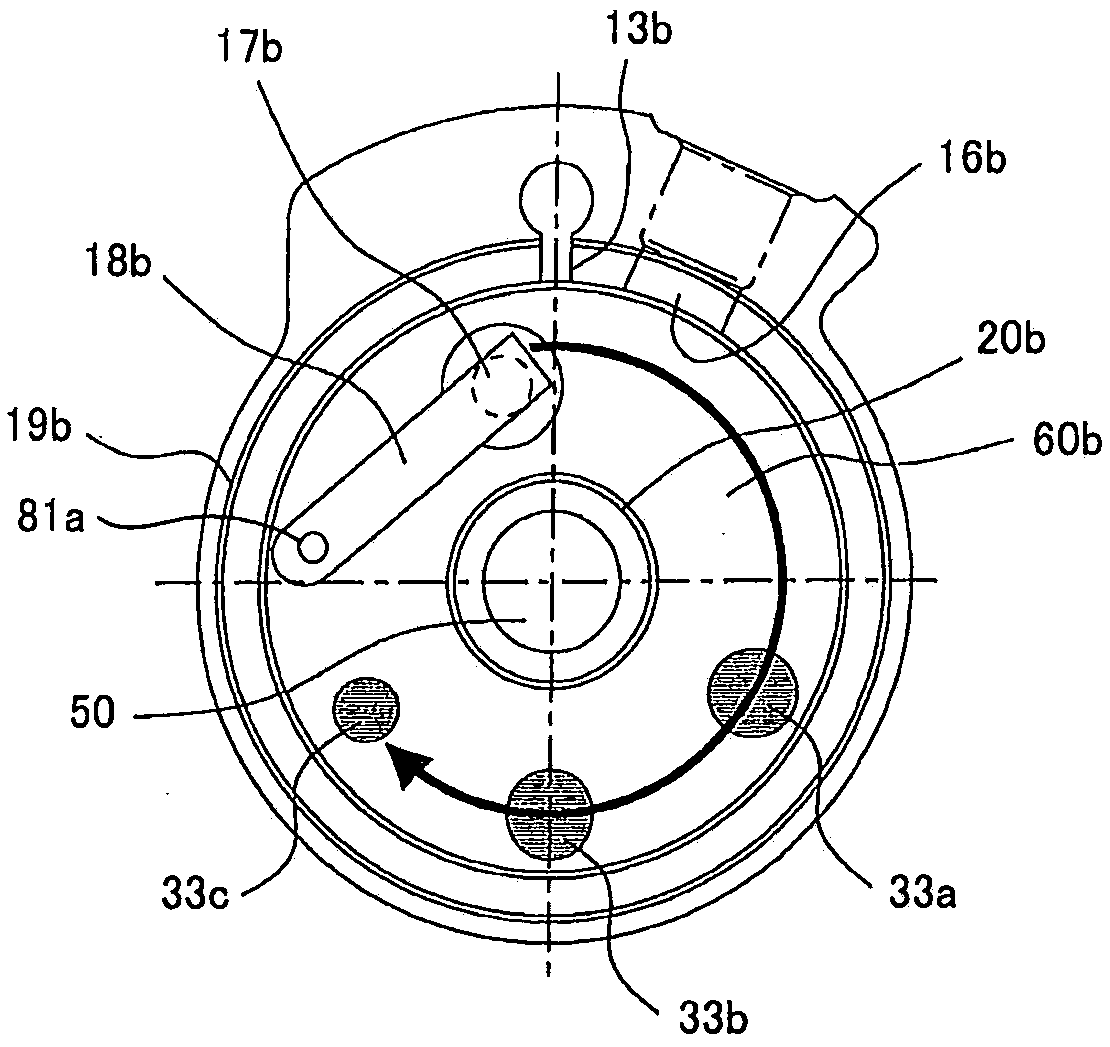

[0034] figure 1 It is a cross-sectional side view showing the overall structure of the multi-cylinder hermetic compressor according to Embodiment 1 of the present invention. figure 2 yes means figure 1 Partial cross-sectional view of the side view of the compression section of the multi-cylinder hermetic compressor. image 3 yes figure 1 A-A arrow direction sectional view. Figure 4 yes figure 1 Sectional view in the direction of the B-B arrow. In addition, since each figure above is drawn schematically, this invention is not limited to embodiment shown in figure.

[0035] Such as Figure 1 ~ Figure 4 As shown, the multi-cylinder hermetic compressor 100 according to Embodiment 1 includes a casing 101 as a hermetic container, a motor unit (hereinafter referred to as "motor") 102 as a driving source provided inside the casing 101, and a 101 inside the compression part 103 . Hereinafter, the configur...

Embodiment approach 2

[0080] Figure 7 is equivalent to showing the shape of the inlet and outlet of the refrigerant passage in the multi-cylinder hermetic compressor according to Embodiment 2 of the present invention. image 3 cutaway view. Figure 8 yes Figure 7 The cross-sectional view in the direction of arrow D-D shows the structure of the second end plate 20b. In addition, in the drawings, the same reference numerals as in the above-mentioned first embodiment are attached to the same functional parts as those in the above-mentioned first embodiment. In addition, in the description, refer to the above figure 1 as well as figure 2 .

[0081] In the multi-cylinder hermetic compressor 100 according to Embodiment 2, as Figure 7 as well as Figure 8 As shown, openings (which may be tapered or chamfered) 33d, 33e, 33f are provided at the inlets and outlets of the refrigerant passages 33a, 33b, 33c, and the openings 33d, 33e, 33f The cross-sectional area of the cross-sectional area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com