Method for laser microdissection, and laser microdissection system

A technology of laser microdissection and laser beam, which is applied in microscopes, laser welding equipment, preparation of test samples, etc., and can solve problems such as multi-time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

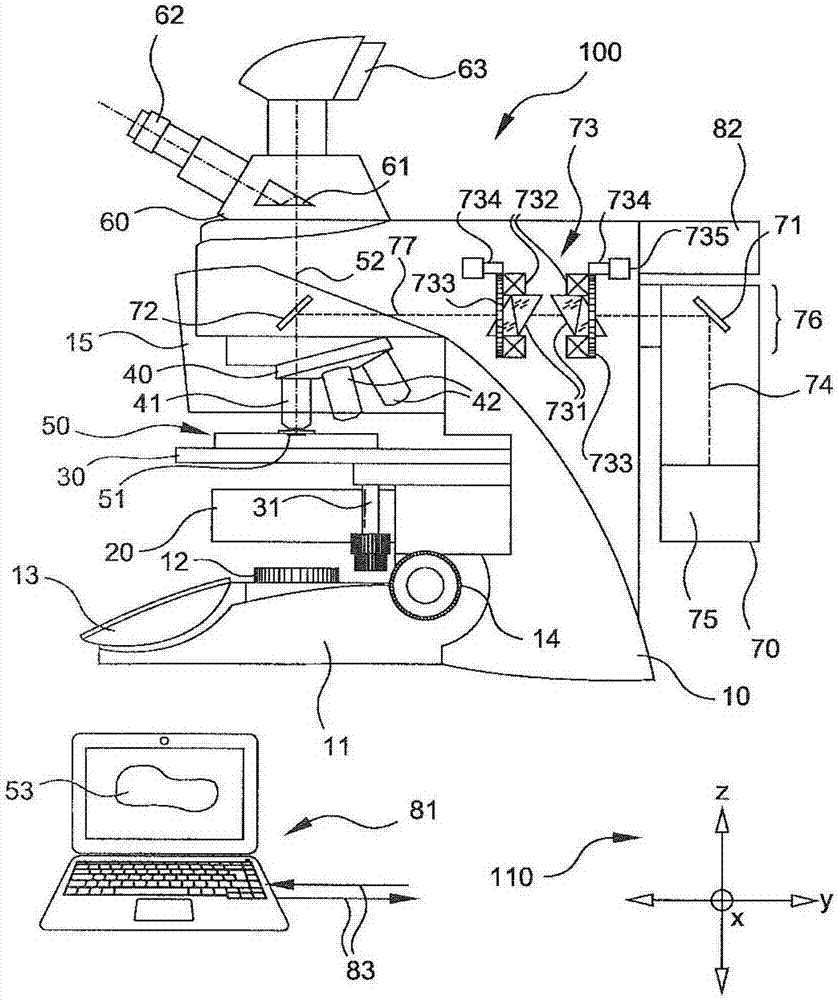

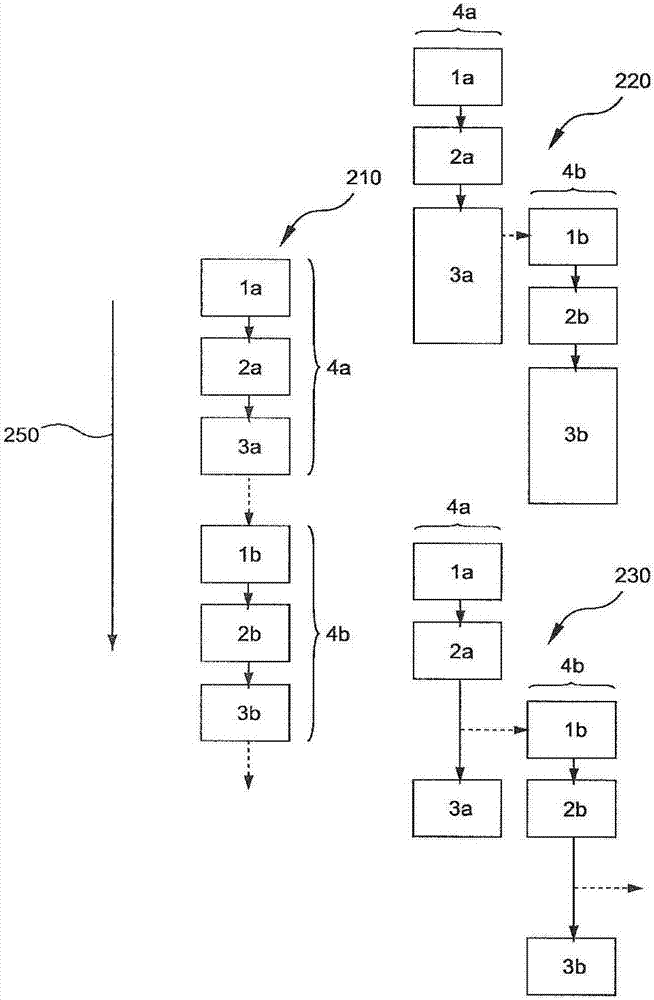

[0057] refer to figure 1 with figure 2 , shows an embodiment of a method (220, 230) for laser microdissection and a laser microdissection system for very fast ablation of cuts. In a laser microdissection system (100), at least a portion of an object (51) to be cut is detected in an image-generating manner (1a) and a first digital object image (53) is concomitantly generated; based on the first digital object image (53 ) defines (2a) a first processing instruction; then, by means of the laser beam (74) of the laser microdissection system (100), the object (51) is processed (3a) in a first processing step according to the first processing instruction. According to an embodiment of the invention, at least part of an object (51) is detected in image-generating manner (1b) and a second digital object image (53) is concomitantly generated; during the execution of the first processing step, based on the second digital object image ( 53) Define (2b) a second processing specificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com