Cyathin compounds, preparation method and application of cyathin compounds to neuroinflammation resisting

A technology for ovonidin and neuroinflammation, applied in the field of medicine, can solve the problems of limited curative effect, inability to restore the cognitive function of patients, and inability to prevent the pathogenesis of AD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

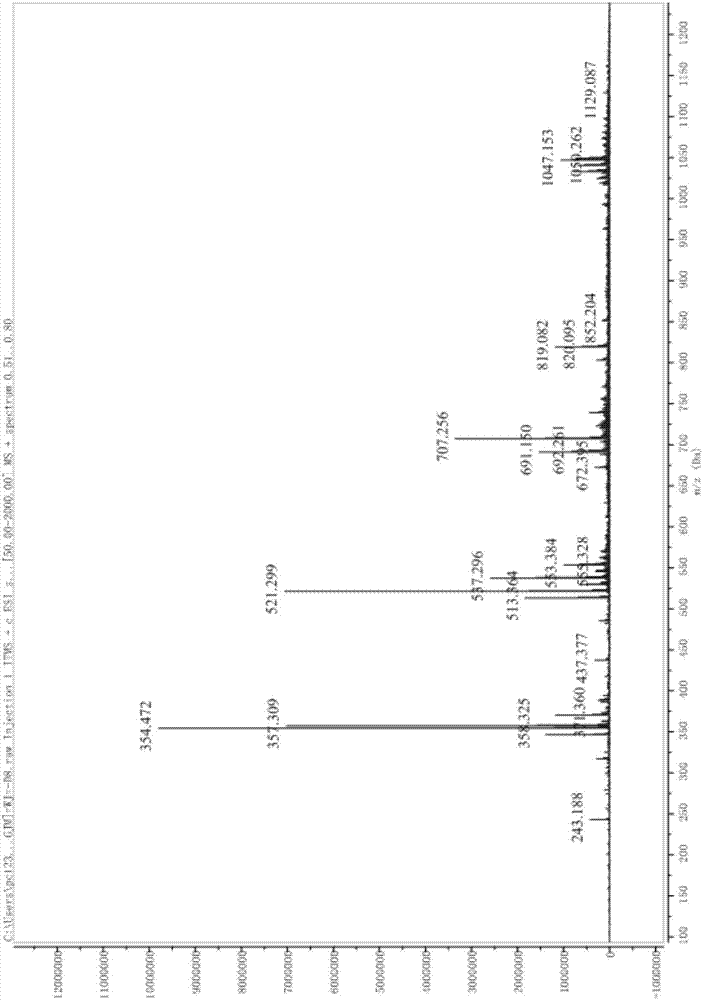

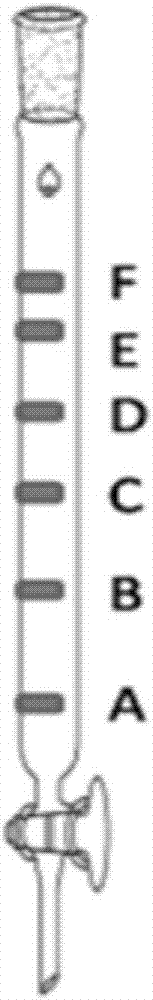

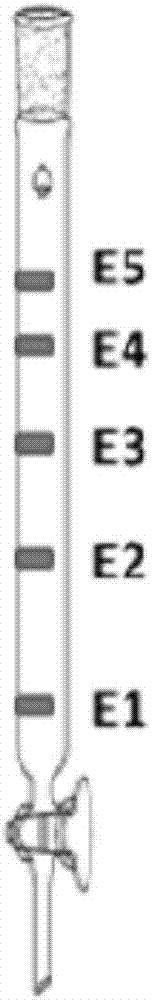

Image

Examples

Embodiment Construction

[0090] The ten compounds of the present invention, nestomycin 1-10, are isolated from the fermented liquid of Cyathus africanus. The Nestella africanum was purchased from the China General Microorganism Culture Collection and Management Center, number: CGMCC 5.1163; the strain was preserved in the Natural Medicinal Chemistry Research Center, School of Chemistry and Pharmacy, Northwest A&F University, number: (No.CA20150728).

[0091] The storage and activation culture conditions of the N. africanus are as follows: the preserved strain adopts a PDA slant medium. To activate the strain, inoculate the strain on a PDA plate, activate and cultivate it at 28°C for 7 days, until the plate is covered with mycelium. PDA plate medium: Each liter medium contains 200g potatoes, 20g glucose, and 16g agar powder.

[0092] One, the extraction method of the compound of the present invention, identification and anti-neurinflammation assay and application:

[0093] 1. Experimental materials ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com