Filling construction method for ordinary-speed railway subgrade in desert area

A common-speed railway and construction method technology, applied to roads, buildings, tracks, etc., can solve problems such as huge project investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

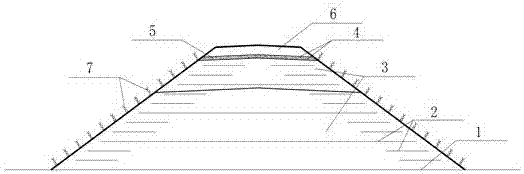

[0024] Such as figure 1 As shown, the filling construction method of ordinary speed railway subgrade in this desert area is:

[0025] ①. Remove the surface soil, and use impact rolling 24 times to treat the base to complete the base treatment;

[0026] ⑴ Construction preparation

[0027] Before subgrade construction, the construction survey work must be done well, including re-measurement of conductors, midlines, benchmarking points, cross-section inspection and supplementary surveying, and addition of benchmarking points.

[0028] According to the restored subgrade center pile, design drawings, construction technology and relevant regulations, determine the specific location of subgrade side piles, subgrade slope toe, and slope protection.

[0029] ⑵, construction process

[0030] Use crawler bulldozers to remove surface humus, grass roots and other sundries within the range of the side piles for the subgrade and the slope toe of the subgrade, with a thickness of 0.3m~0.6m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com