Cantilever construction method for arch rib bridge girder

A construction method and cantilever technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of unbalanced load ends, prone to misplacement and leakage of slurry at joints, and many technical difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The present invention will be further described below in conjunction with accompanying drawing.

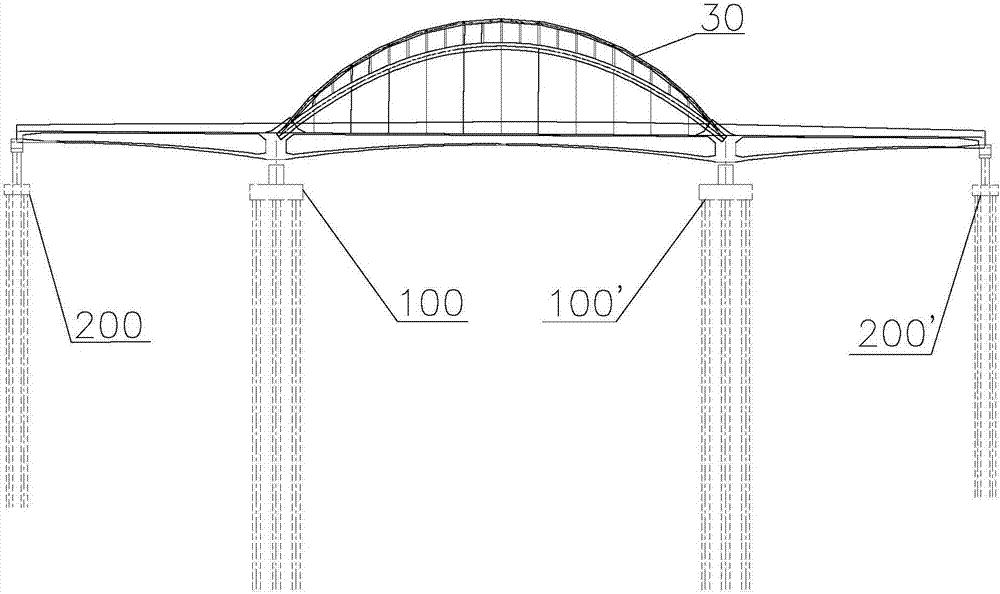

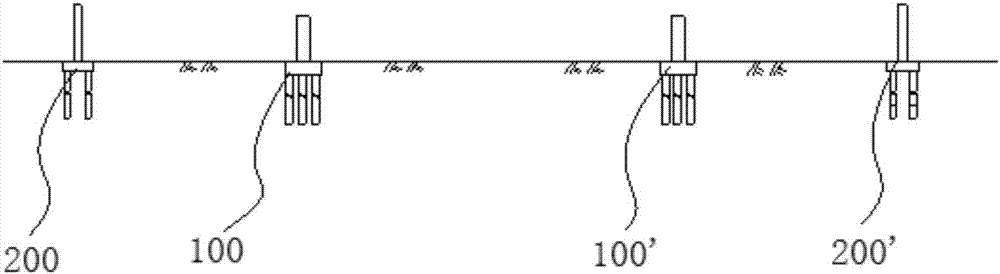

[0078] see first figure 1 , the arch rib bridge is set with two main piers 100, 100' and two side piers 200, 200', the bridge between the middle two main piers 100, 100' is the main bridge, and the upper part of the main bridge adopts the arch beam combination system - new Moon arch structure 30; the two main piers 100, 100' and the two side piers 200, 200' are solid rectangular piers, and the piles are connected to the platform foundation; the main beam is a variable-height prestressed concrete continuous box girder, and the The five-chamber straight web form of the box, the roof of the box girder is provided with a two-way 2% transverse slope; the two sides of the No. No. box girder segment 10, and set a mid-span closing section 11 and two side-span closing sections 11'.

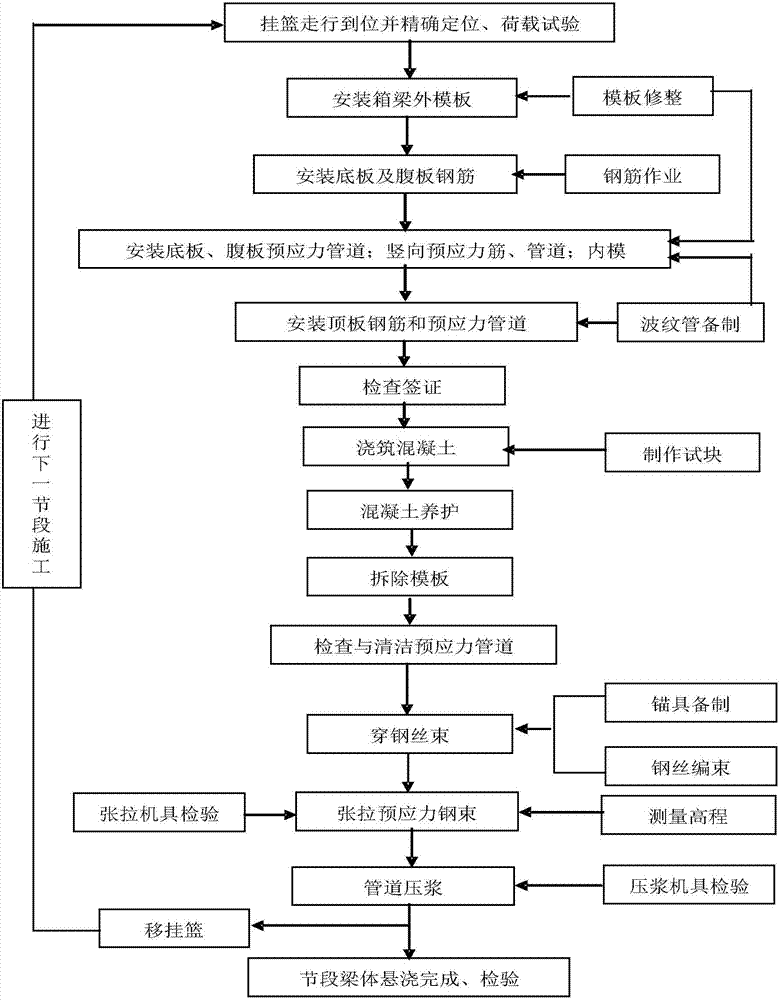

[0079] see again Figure 2 to Figure 10 , the cantilever construction method of arch rib bridge g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com