Combined type fabricated wall body

A combined type and wall technology, which is applied in the direction of building components, buildings, building structures, etc., can solve problems such as complex installation process and complex wall structure, achieve high energy saving level, save installation man-hours, reduce production costs and protect the environment cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

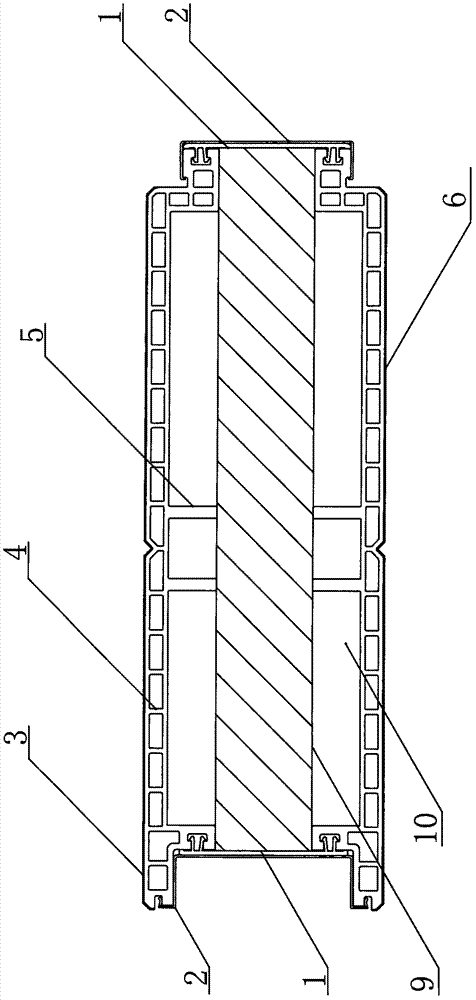

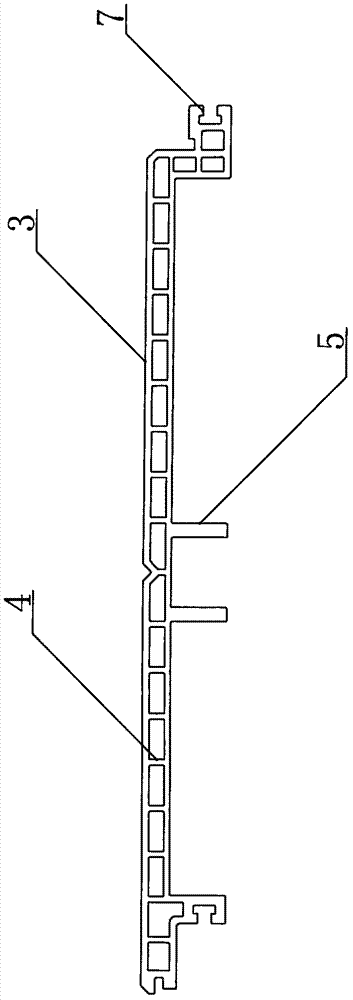

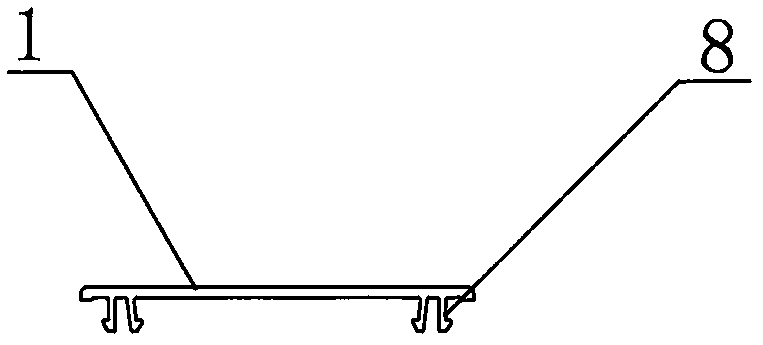

[0018] Such as Figure 1-3 As shown, a combined assembled wall body of the present invention includes an exterior wall panel 3 and an interior wall panel 6 with the same structure, the length of the exterior wall panel 3 and the interior wall panel 6 is 300 mm, and the exterior wall panel 3 and the interior wall panel 6 are opposite to each other. set up. The left and right ends of the outer wall panel 3 and the inner wall panel 6 are respectively processed with a mounting groove 7, and the left and right sides between the outer wall panel 3 and the inner wall panel 6 are respectively provided with a plug piece 1 with a width of 70 mm. Part 1 is processed with two clamping joints 8, and the clamping joints 8 are installed in the mounting grooves 7 at the left and right ends of the outer wall panel 3 and the inner wall panel 6. The outer wall panel 3, the inner wall panel 6 and the two plugs 1 jointly form a cavity, and the middle part of the cavity is provided with a thermal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com