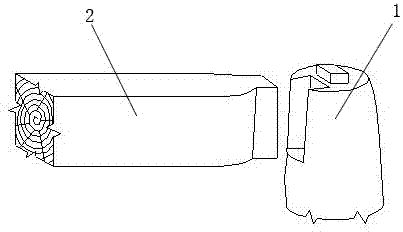

Reinforcing repairing structure for ancient building eave column and single-architrave node

A technology of ancient buildings and joints, which is applied in the field of strengthening and repairing the joints of ancient building eaves columns and single-front architraves. Material waste and other issues can be improved to improve overall stability, reduce the chance of damage, and maintain stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

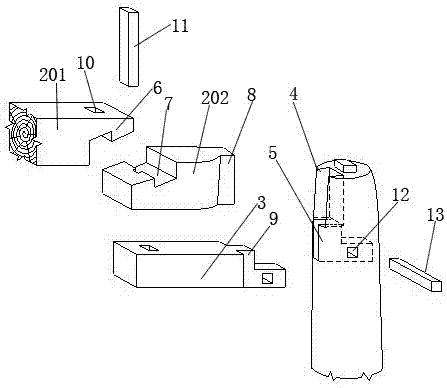

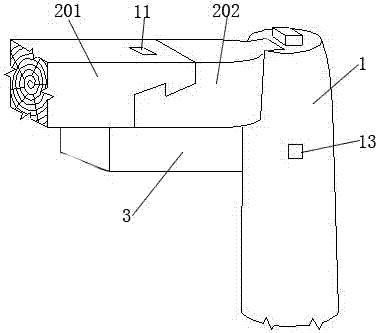

Method used

Image

Examples

Embodiment 1

[0037] "Auxiliary stage pillars" is the name of the large wooden components of Song-style buildings, also known as "auxiliary stage eaves pillars" or "lower eaves pillars". It is used for the winding corridor on the building platform. From the plane view, this kind of column is at the outermost end of the building, supporting the eaves of the auxiliary steps, and is the main component of the wooden frame of the auxiliary steps. Its main features are as follows: 1. The space formed by the "sub-level columns" is smaller than the space of the indoor interior columns; Step pillars" have a smaller diameter than the inner pillars.

[0038] In ancient building repair projects, it is very common for tenons to be pulled out and tenons to be damaged at the joints of single-front architraves and auxiliary eaves columns. This patented technology can be used for reinforcement and repair.

[0039] The specific reinforcement steps are as follows:

[0040] ① Saw and chisel off the back shou...

Embodiment 2

[0048] In ancient building repair projects, it is also very common to have tenons pulled out and tenons damaged at the joints between the single-front architrave and the eaves column of the temple body. This patented technology can be used for reinforcement and repair. The specific reinforcement steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com