Fiber glass reinforced plastics anchor rod supporting structure and fiber glass reinforced plastics anchor rod

A technology of bolt support and glass fiber reinforced plastic, which is applied in the installation of bolts, mining equipment, earth-moving drilling, etc., can solve the problems of low stability and reliability of support, reducing the fixing effect of bolts, and unavoidable slurry leakage. , to achieve the effect of simple structure, reasonable design, improved stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to enhance the understanding of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

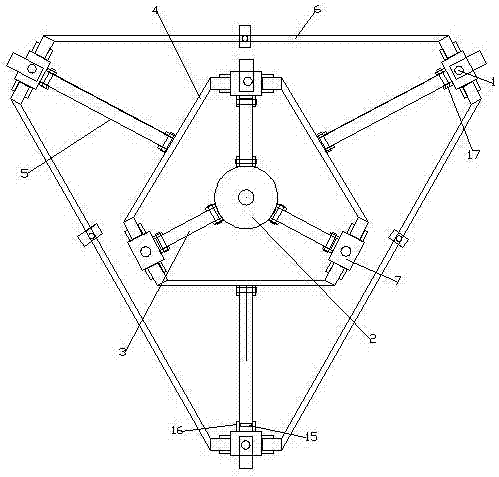

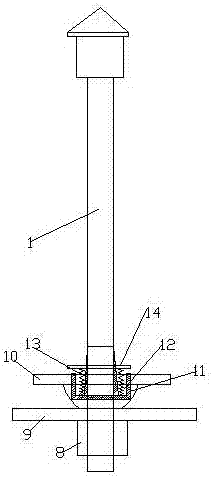

[0015] Such as Figure 1-2 As shown, the present invention is a FRP bolt support structure and a FRP bolt, including a support frame and a FRP bolt body 1, characterized in that: the support frame includes a support base plate 2, which is arranged on the outside of the support base plate 2 There are several first connecting arms 3, an inner connecting arm 4 is arranged at the ends of every two adjacent first connecting arms 3, and a second connecting arm 5 is arranged in the middle of each inner connecting arm 4. An outer connecting arm 6 is arranged between the two second connecting arms 5, and every two inner connecting arms 4 and the first connecting arm 3 are co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap