Crawler type driving walking support mechanism applicable to tunneling machine

A crawler-type, roadheader technology, which is applied to mine roof supports, mining equipment, earthwork drilling, etc., can solve the problems of small supporting area, difficulty in advancing or retreating of supporting devices, hurting people, etc., and achieve a large supporting area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

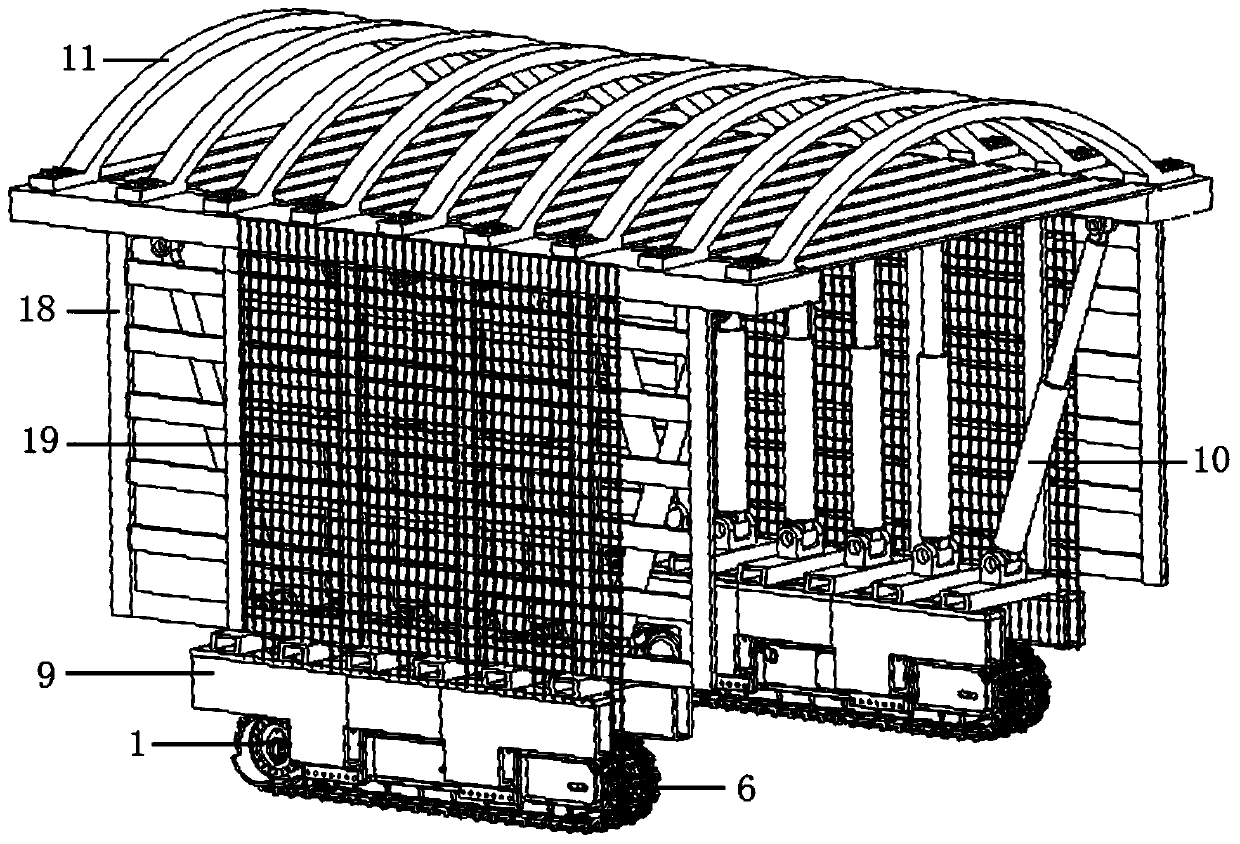

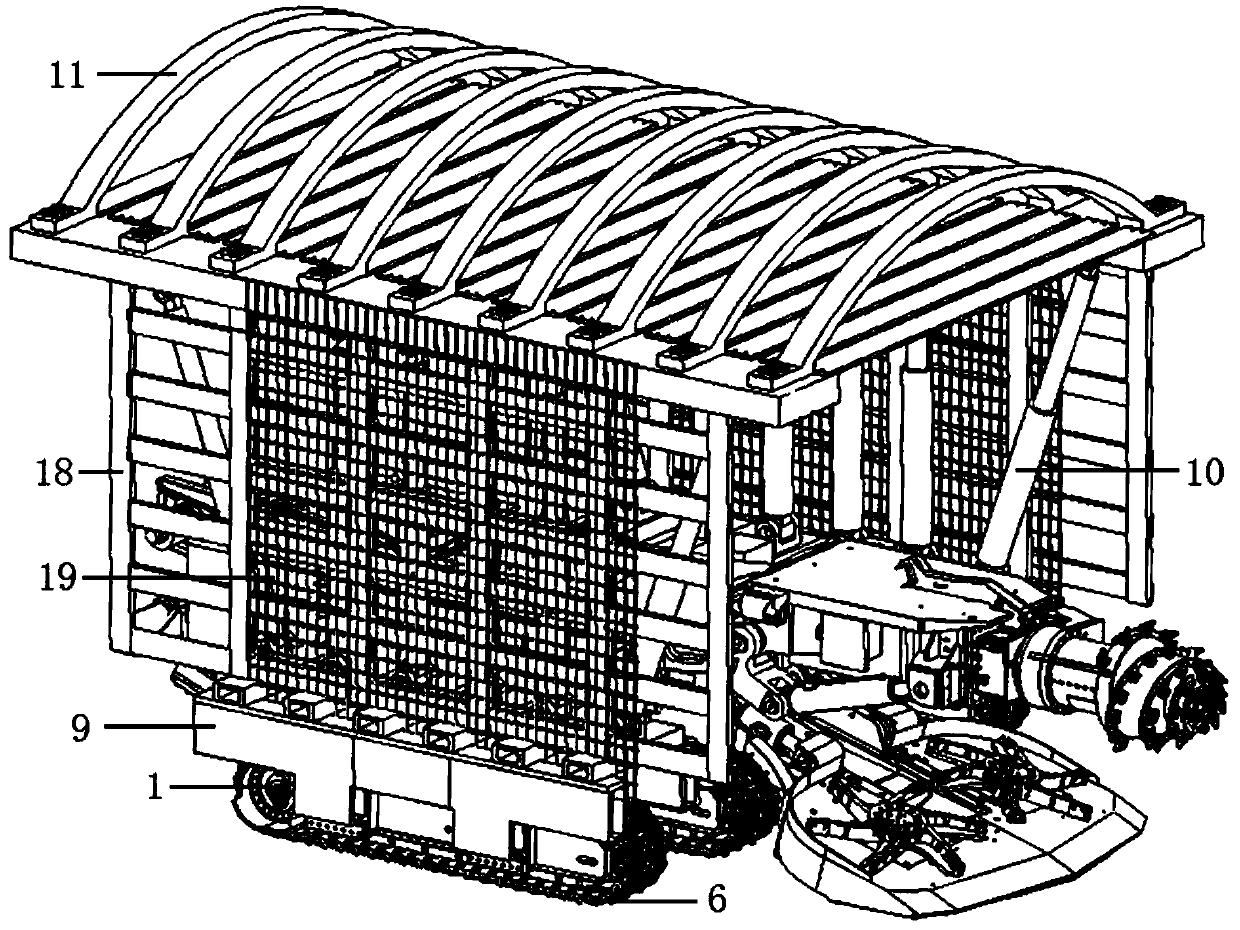

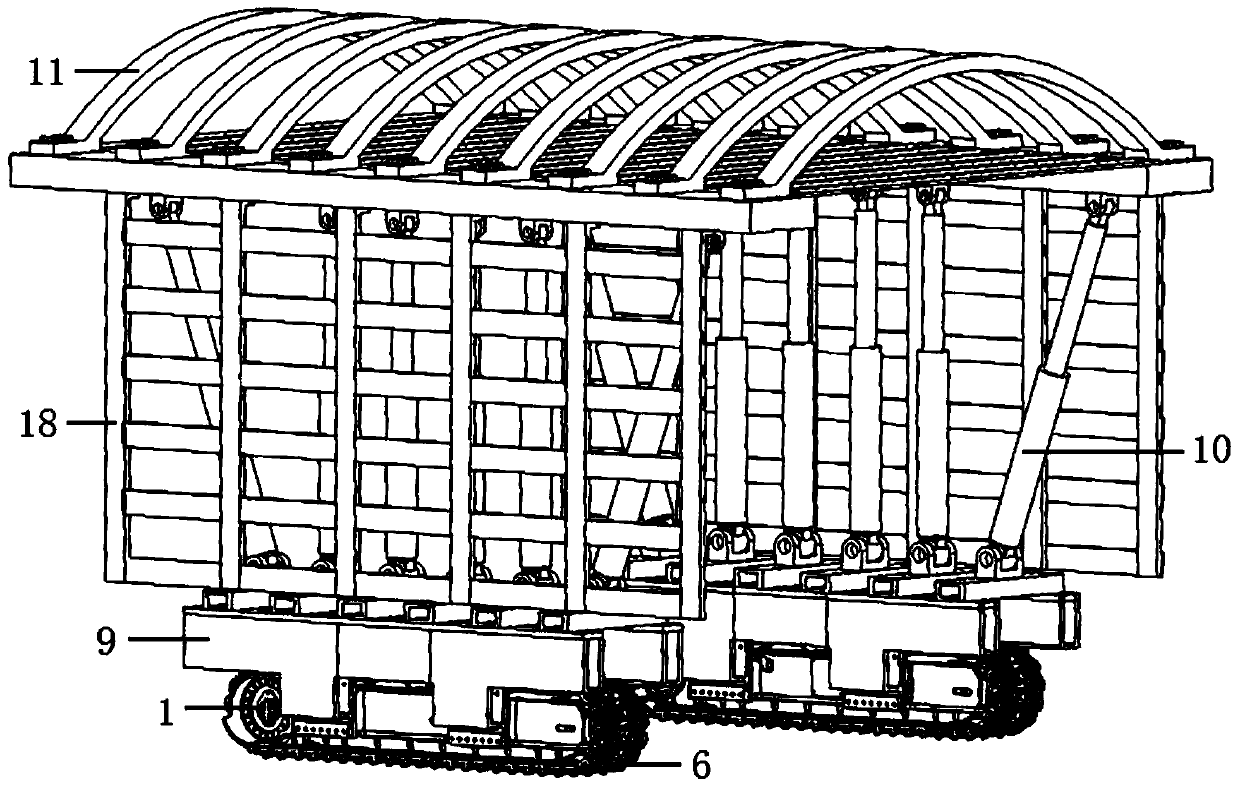

[0023] Such as Figure 1-8 As shown, a crawler-type active walking support mechanism suitable for roadheaders includes a traveling part and a supporting part; the traveling part includes a hydraulic motor 1, a reducer 2, a sprocket 3, a tension wheel 4, and a support Wheel 5, track chain 6, wheel frame 7 and track chain friction plate 8; the hydraulic motor 1 and reducer 2 are installed on the front end of wheel frame 7, the power output end of hydraulic motor 1 and the power input end of reducer 2 The sprocket 3 is fixedly set on the power output end of the reducer 2; the tensioning wheel 4 is installed on the rear end of the wheel frame 7, and the tensioning wheel 4 and the sprocket 3 are connected by a track chain 6, so The number of supporting wheels 5 is several, and several supporting wheels 5 are installed side by side under t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap