Step type inspection well structure for thermal insulation center trench below tunnel inverted arch

An inspection well and step-type technology, which is applied to waterway systems, drainage structures, drainage, etc., can solve the problems of tunnel drainage system inspection and maintenance in cold regions and increase the workload, so as to improve the ability of cold protection and heat preservation, and reduce the amount of engineering , to ensure the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

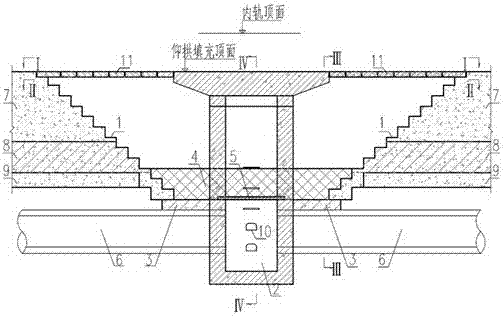

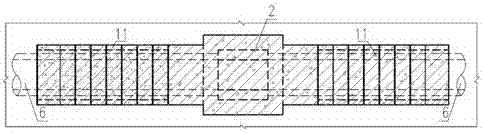

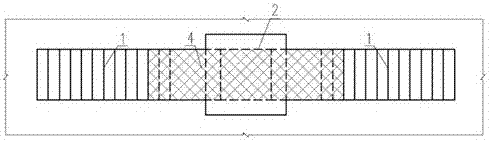

[0029] Such as Figure 1~5 As shown in the figure, a stepped inspection well structure of the thermal insulation central ditch under the inverted arch of the tunnel includes the thermal insulation inspection well 2 of the deep buried central ditch and the tunnel deep buried central tunnel arranged longitudinally under the inverted arch and connected with the thermal insulation inspection well 2 of the deep buried central ditch. ditch6. The thermal insulation inspection well 2 of the deep buried central ditch is longitudinally provided with a lateral step ladder 1, and the lower end of the lateral step ladder 1 is connected to the thermal insulation inspection well 2 of the deep buried central ditch through an inspection platform 3, and the thermal insulation inspection well 2 of the deep buried central ditch The inspection well 2 corresponds to the maintenance p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com