A pressure regulating device for a heating system

A heating system and pressure regulation technology, applied in the direction of valve operation/release device, electric fluid pressure control, valve device, etc., can solve the problems of low pressure regulation accuracy, large delay, cumbersome pressure regulation process, etc., to achieve Convenient operation, simple device structure and large pressure regulation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

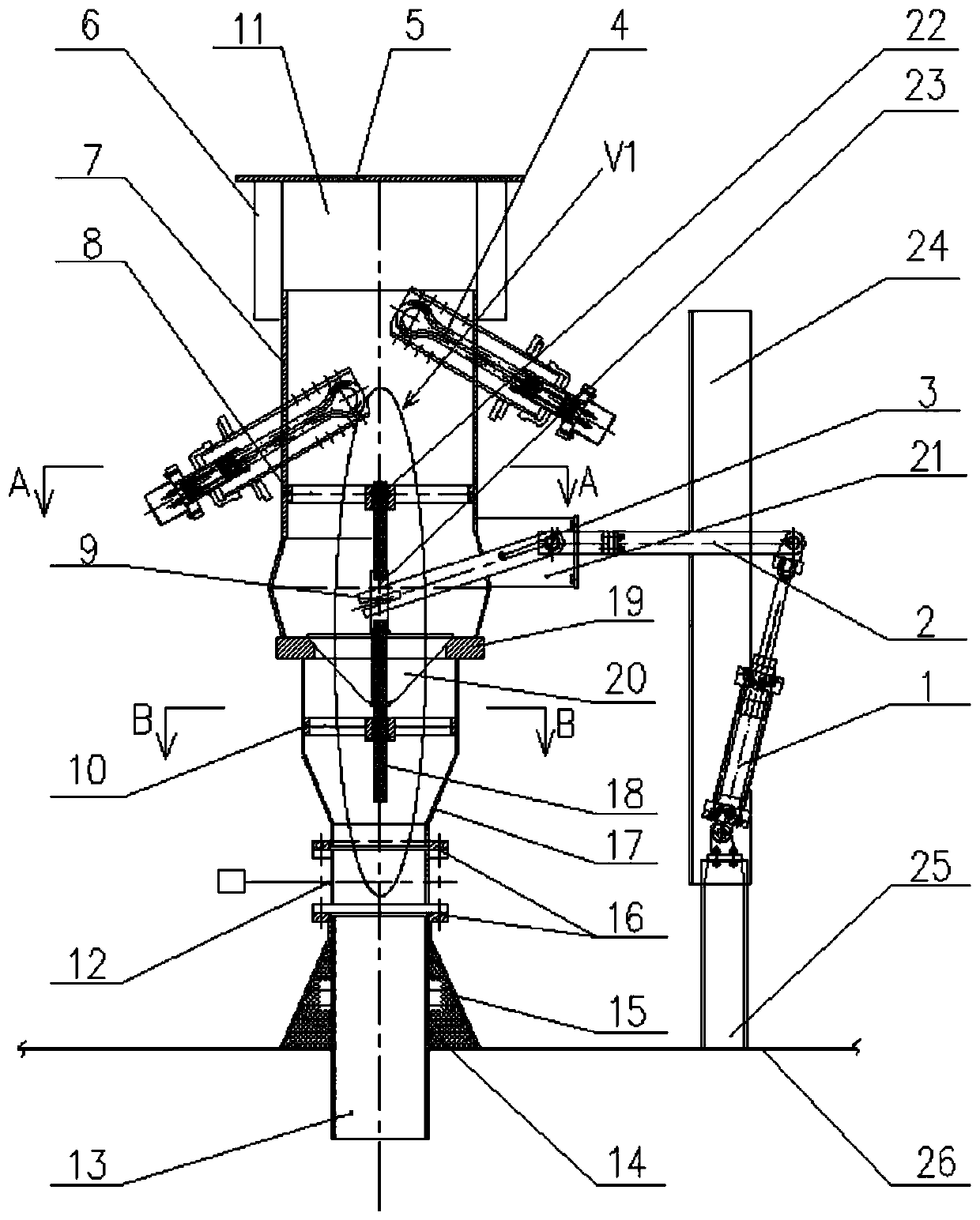

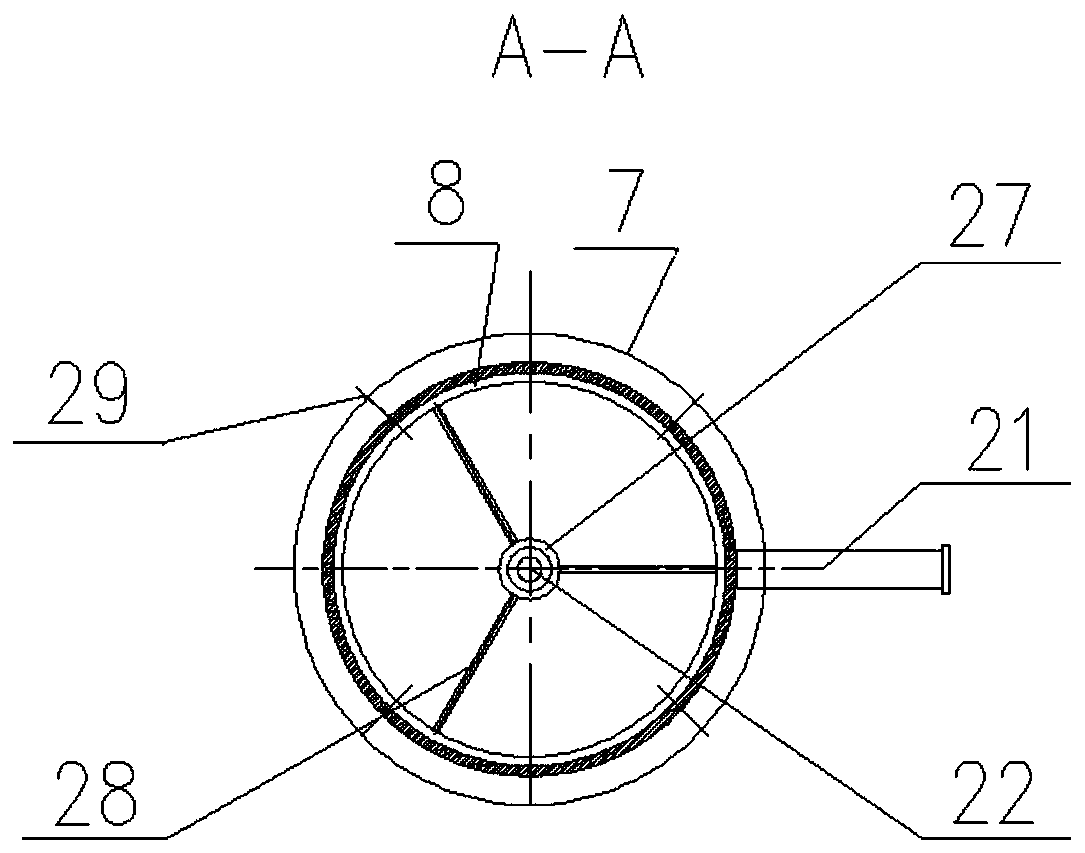

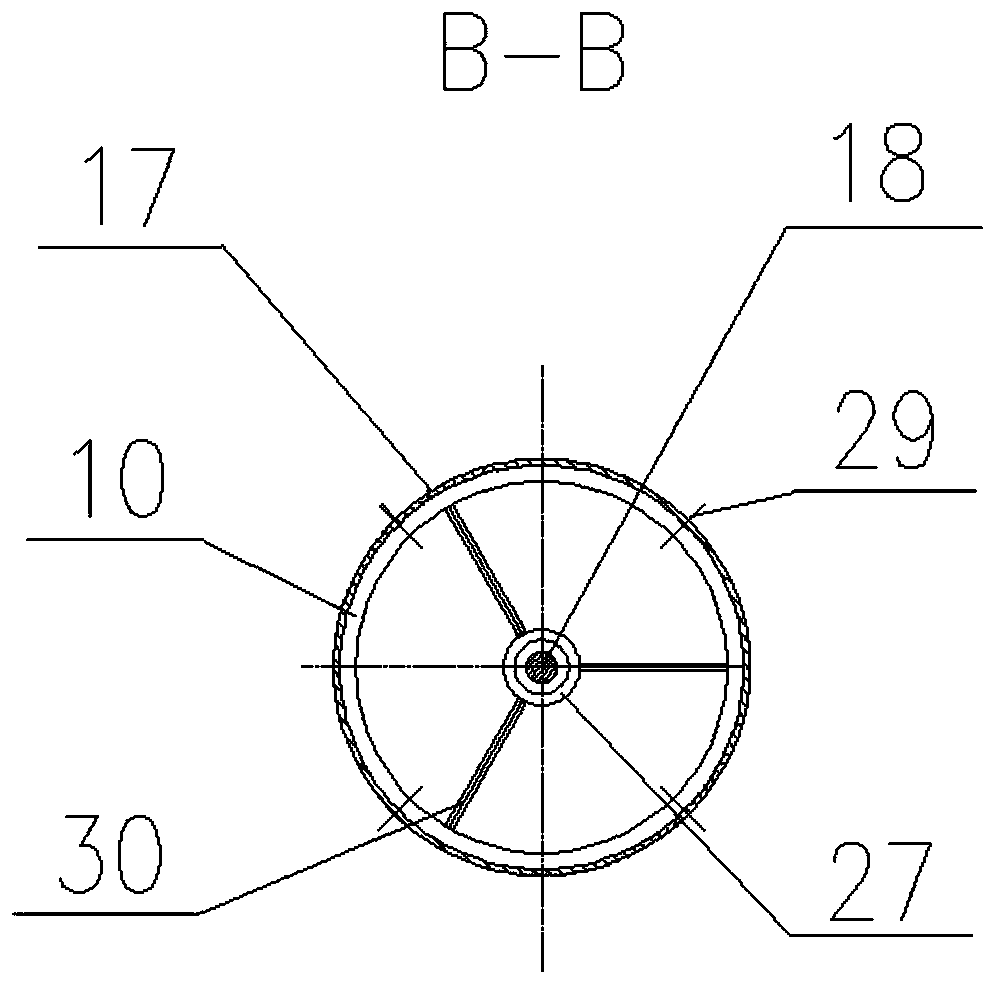

[0025] Embodiment 1: The present invention provides a kind of pressure regulating device for heating system, its structure is as follows figure 1 , 6 As shown, it includes a shell part, a pneumatic conical plug coarse adjustment part, an electric valve fine adjustment part, a glow heater 4 and a control part; the shell part is provided with a guide cylinder 13, a support cylinder 15, an electric valve 12, Lower cavity 17, gas channel cavity 7, connection plate 6, fire baffle 5 and exhaust port 11, the upper surface of the guide tube 13 is provided with a support tube 15, the gap between the guide tube and the support tube Refractory fibers 14 are arranged between them, and the refractory fibers are used for heat insulation and air tightness improvement. The lower end of the supporting cylinder is connected with the furnace shell steel plate of the heating system, and the lower part of the guide cylinder extends into the furnace of the heating system.

[0026] The top of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com