Preparation process of electrolytic aluminum

A preparation process, a technology for electrolytic aluminum, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of delaying normal production, unavailability of slabs, and inconspicuous white streaks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

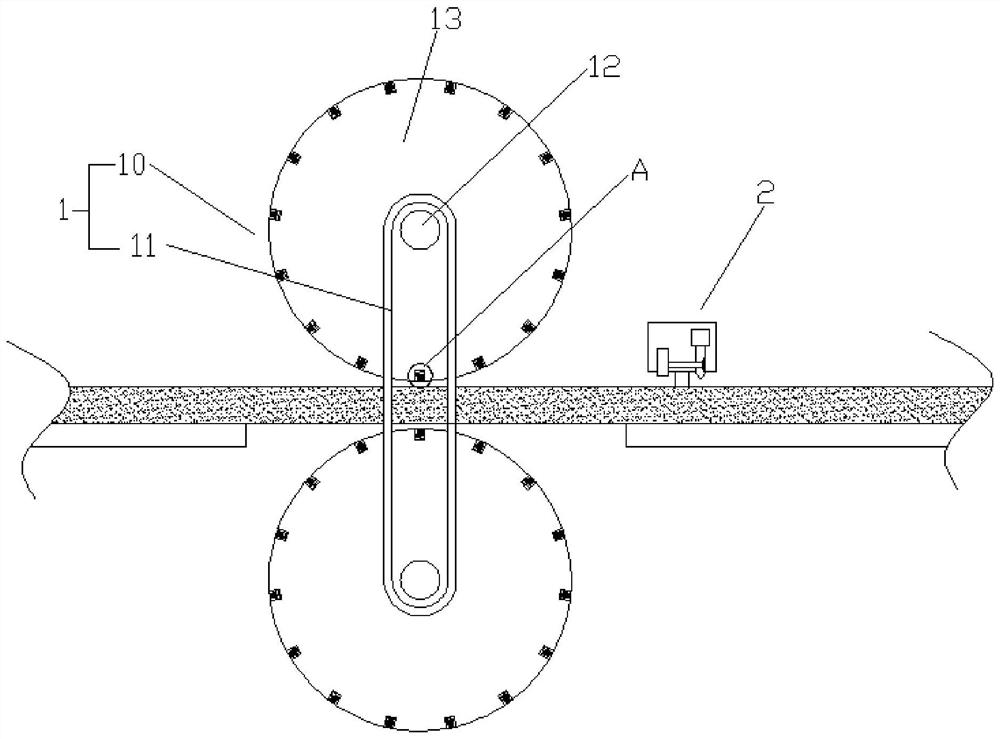

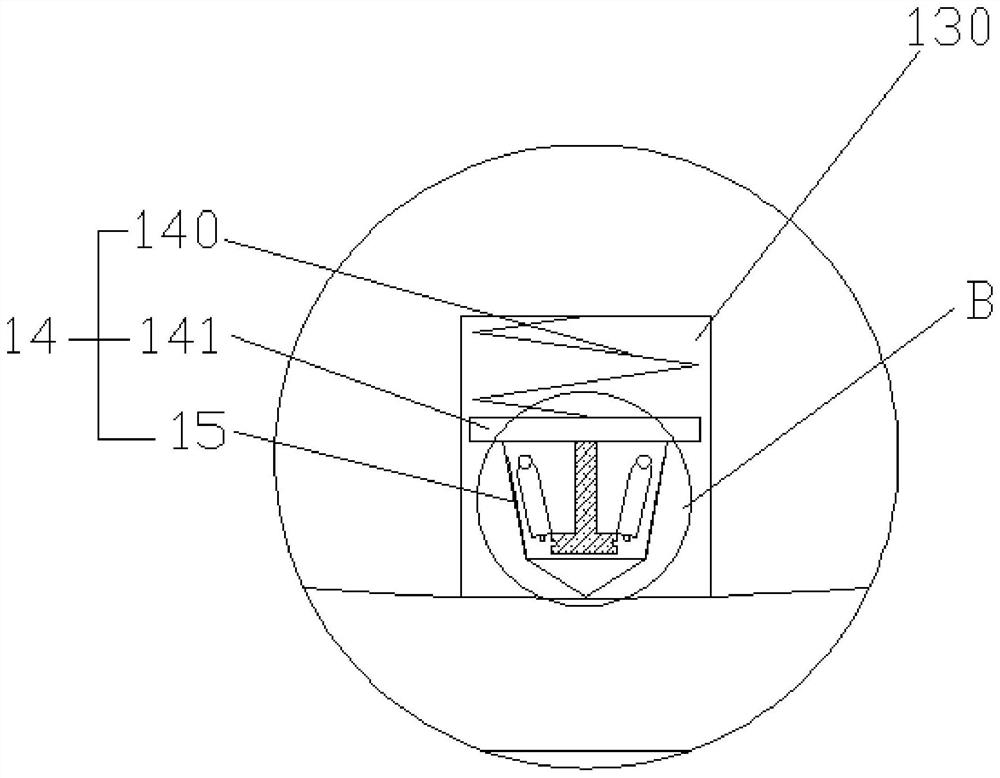

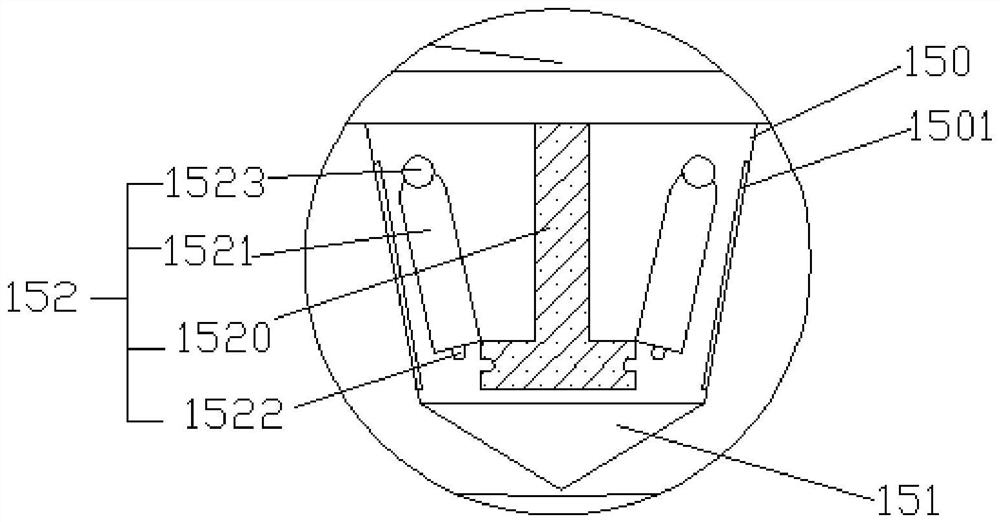

[0031] Attached below figure 1 To attach Figure 5 The present invention is further described with embodiment:

[0032] A process for preparing electrolytic aluminum, the method comprising the following steps:

[0033] A. Electrolysis: The molten aluminum is separated by cryolite-alumina molten salt electrolysis in the electrolytic cell, and the other anode gas is discharged from the electrolytic cell to ensure the purification and clarification of the molten aluminum;

[0034] B. Refining: transfer the electrolytic aluminum liquid into the chute, and then carry out crystal force refinement treatment, on-line degassing treatment and on-line filtration in the chute to obtain a molten aluminum melt that meets the pouring requirements;

[0035] C. Casting: The molten aluminum solution is cast on-line with a pouring machine to form an aluminum ingot;

[0036] D. Rolling and sawing: the aluminum ingot is rolled by the rolling mechanism, and then sawed by the sawing mechanism, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com