Four-direction spring buckle and four-direction synchronous advancing and retreating method

A four-direction, spring buckle technology, applied in metal processing and other directions, can solve the problems of small deformation, unable to achieve predetermined functions, not smooth enough, etc., to achieve smooth operation, improved mechanical connection, convenient and flexible use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

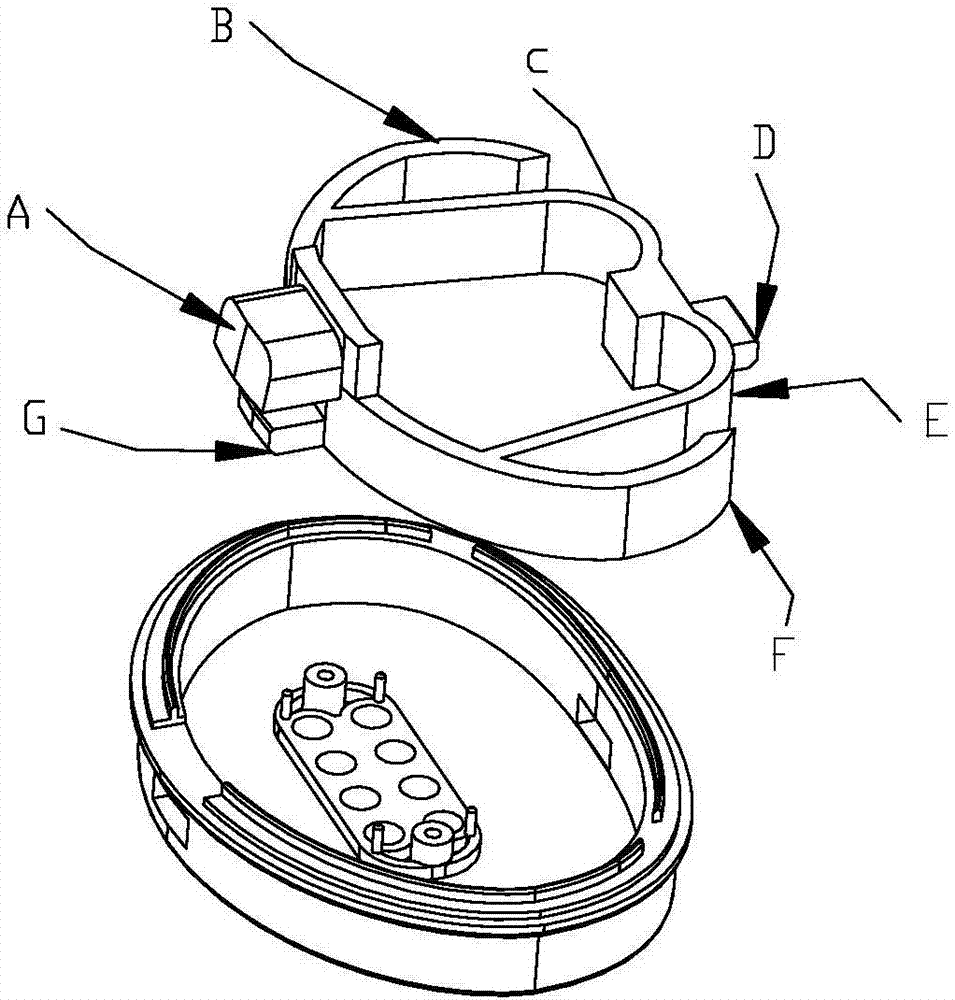

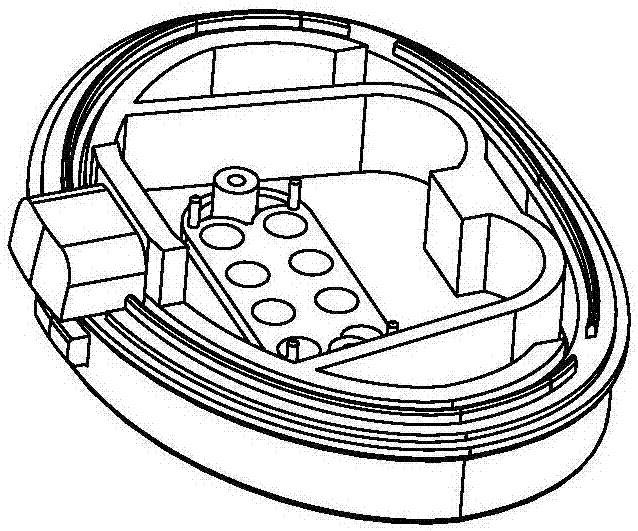

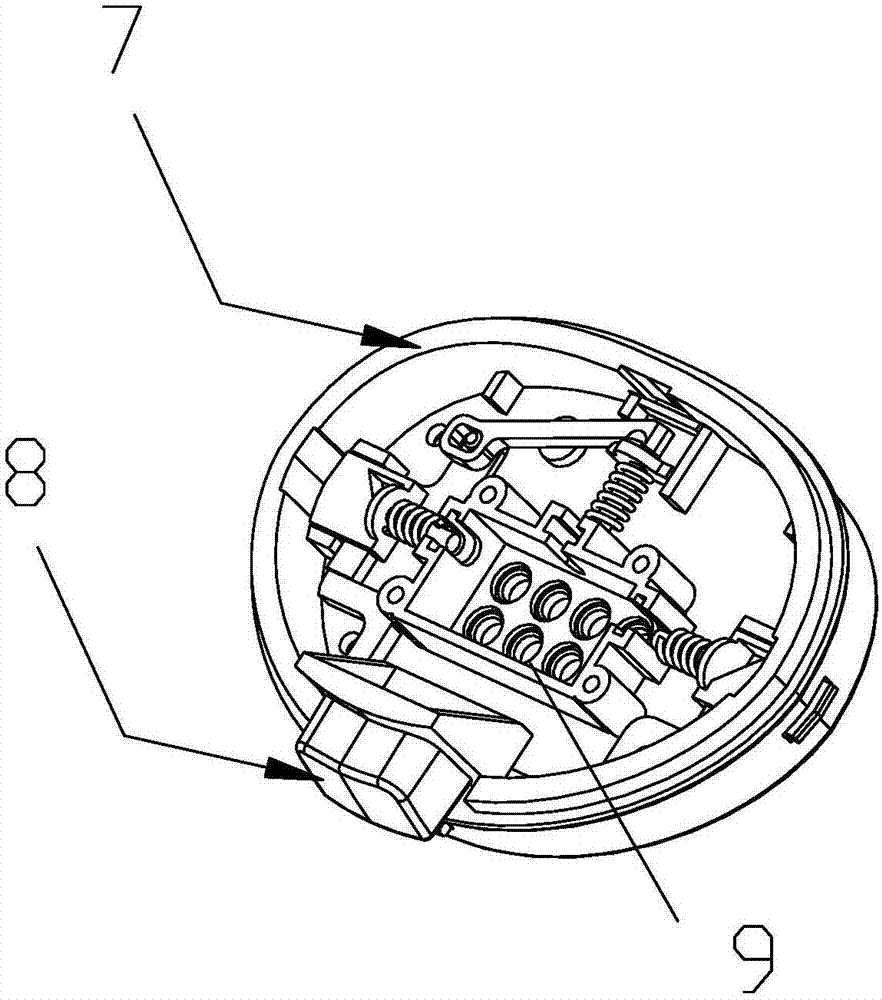

[0045] Embodiment 1: as Figure 3-9 , a four-way spring buckle, comprising a bow-shaped connector 10, a front fastener 1, a rear fastener 4, a left fastener 2, and a right fastener 5; the rear fastener is arranged in the middle of the bow connector;

[0046] The left fastener and the right fastener are respectively located at the two ends of the bow-shaped connector;

[0047] Both the left side fastener and the right side fastener are provided with steering force guide parts; the two ends of the bow-shaped connector are in contact with the left side fastener and the right side fastener respectively;

[0048] The front fastener, the left fastener and the right fastener are provided with springs 3; the springs are used for reset and for pressing the central part 9; the central part is used to provide intermediate support for the spring fasteners.

[0049] One end of the bow-shaped connector is also connected to one end of the pry bar 6, and the other end of the pry bar is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com