A kind of electrolytic manganese slag-based paste filling material and preparation method thereof

An electrolytic manganese slag-based paste and electrolytic manganese slag-based technology are applied in the field of electrolytic manganese slag-based paste filling materials, which can solve the problems of affecting popularization and use and high filling costs, and achieve low heavy metal leaching concentration, good filling fluidity, and low energy consumption. can low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

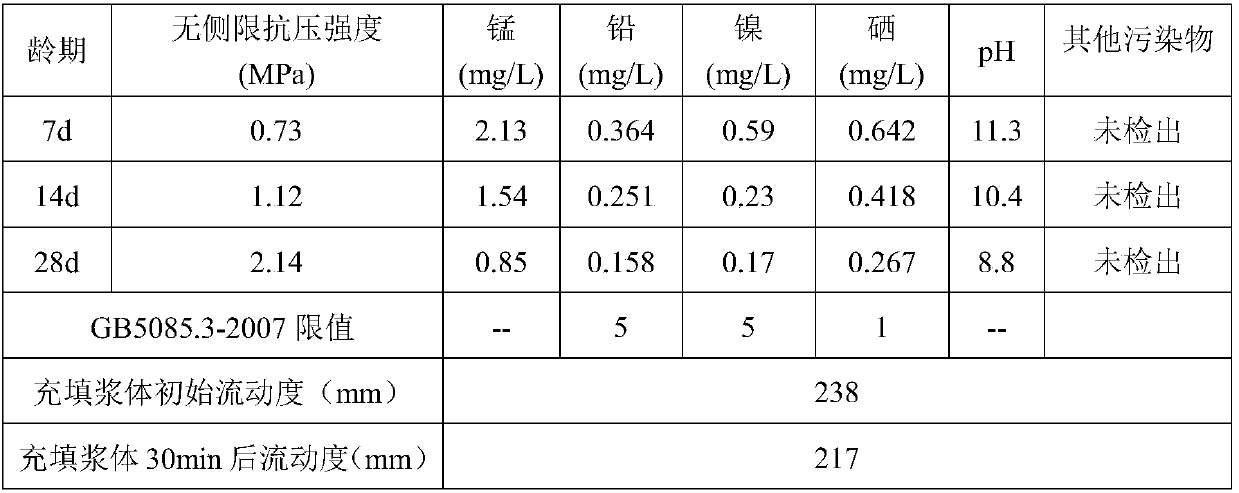

Embodiment 1

[0014] An electrolytic manganese slag-based paste filling material is made of the following raw materials in parts by weight: 75% of the original electrolytic manganese slag, 5% of carbide slag, and 20% of electrolytic manganese slag-based cement (the electrolytic manganese slag-based cement is made of 78% finely ground electrolytic manganese slag powder, 10% boiling slag, 3% cement kiln dust, 5% phosphorus slag powder, 3% petroleum coke desulfurization ash and 1.0% additive); the moisture content of the filling material is 30%.

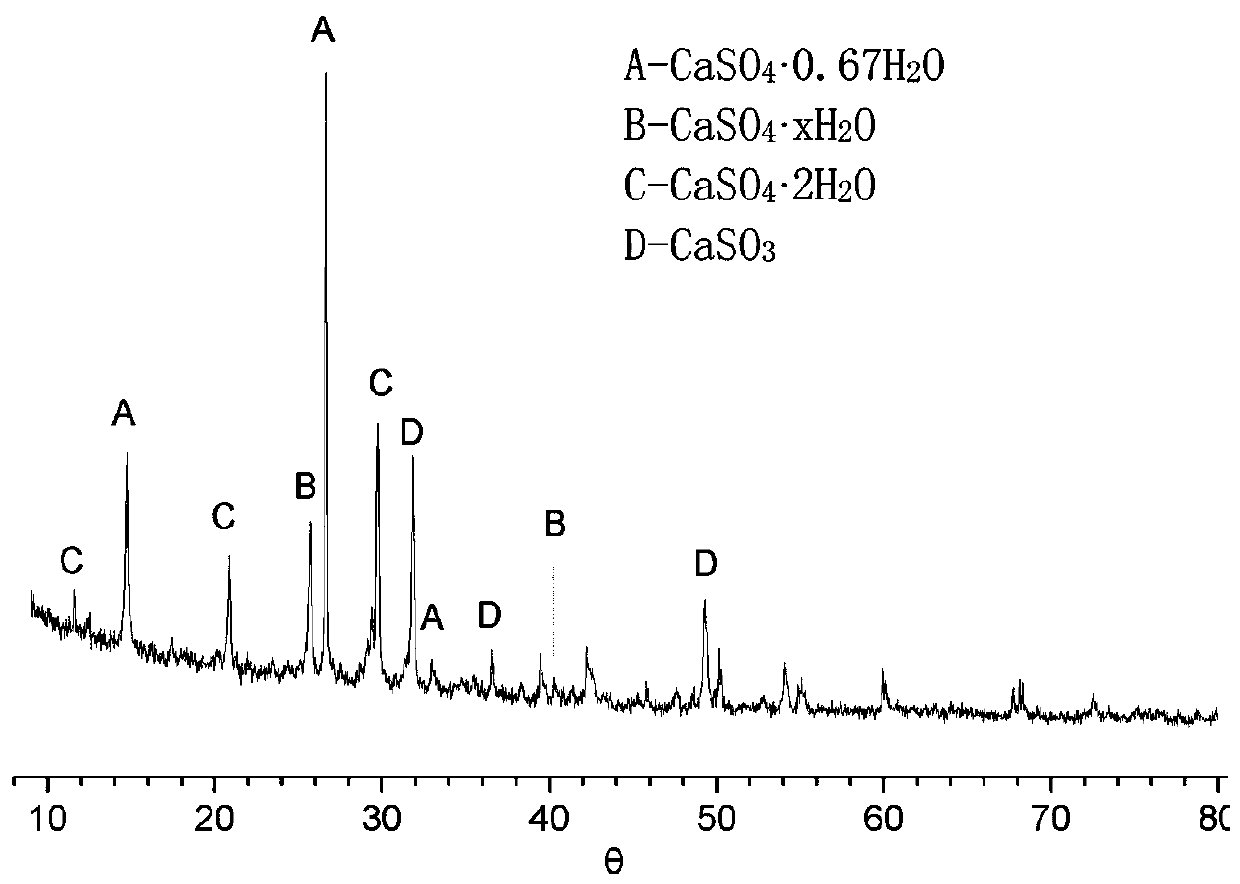

[0015] It is taken from electrolytic manganese slag of a certain enterprise, dried and ground, and the specific surface area is 770.3m 2 / kg, its chemical composition and mineral composition are as follows.

[0016] Table 1 Chemical composition of electrolytic manganese slag

[0017]

CaO

SiO 2

al 2 o 3

MgO

SO 3

Fe 2 o 3

K 2 o

MnO

Cr 2 o 3

P 2 o 5

TiO 2

content

18...

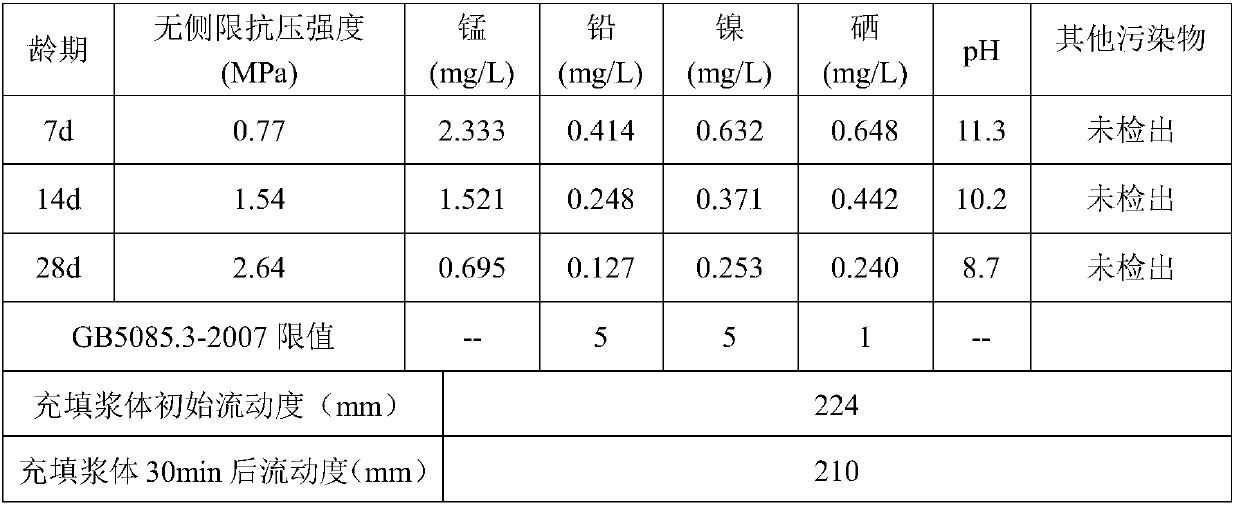

Embodiment 2

[0021] An electrolytic manganese slag-based paste filling material is made of the following raw materials in parts by weight: 80% of the original electrolytic manganese slag, 4% of calcium carbide slag, and 16% of electrolytic manganese slag-based cement (the electrolytic manganese slag-based cement is made of Ground electrolytic manganese slag powder 65%, boiling slag 10%, cement kiln dust 10%, phosphorus slag powder 11%, petroleum coke desulfurization ash 3% and admixture 1.0%); the moisture content of the filling material is 26%.

[0022] Firstly, use finely ground electrolytic manganese slag powder as the main raw material, add boiling slag, cement kiln dust, phosphorus slag powder, petroleum coke desulfurization ash, and additives in a specified proportion, and stir for 10 to 20 minutes to make it evenly mixed to form electrolytic manganese slag base binder. Mix the original electrolytic manganese slag, calcium carbide slag, and electrolytic manganese slag-based cement in...

Embodiment 3

[0025] An electrolytic manganese slag-based paste filling material is made of the following raw materials in parts by weight: 86% of the original electrolytic manganese slag, 3% of calcium carbide slag, and 11% of electrolytic manganese slag-based cement (the electrolytic manganese slag-based cement is made of 60% ground electrolytic manganese slag powder, 23% boiling slag, 3% cement kiln dust, 6% phosphorous slag powder, 5% petroleum coke desulfurization ash and 3.0% admixture); the moisture content of the filling material is 20%.

[0026] Firstly, use finely ground electrolytic manganese slag powder as the main raw material, add boiling slag, cement kiln dust, phosphorus slag powder, petroleum coke desulfurization ash, and additives in a specified proportion, and stir for 10 to 20 minutes to make it evenly mixed to form electrolytic manganese slag base binder. Mix the original electrolytic manganese slag, calcium carbide slag, and electrolytic manganese slag-based cement in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com