Luminous brake disc with heat-dissipating grooves

A heat dissipation groove and brake disc technology, which is applied in the field of brake discs, can solve the problems of easy heating of brake discs, and achieve the effects of easy heating, broad market prospects, and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

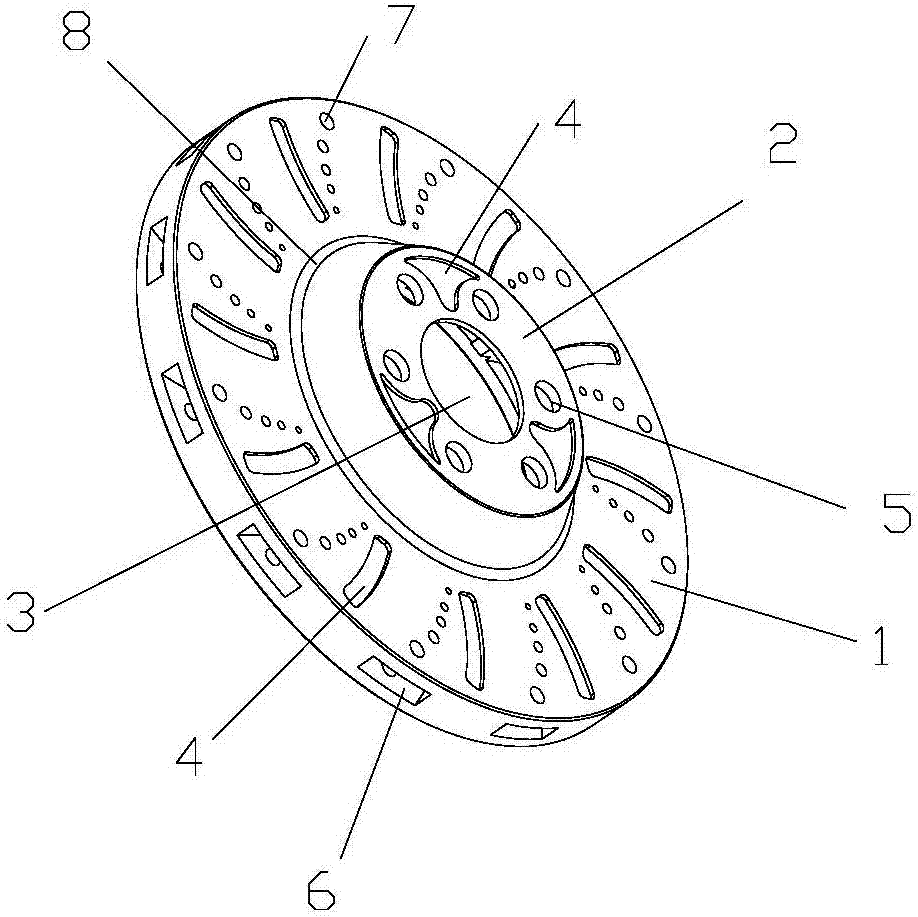

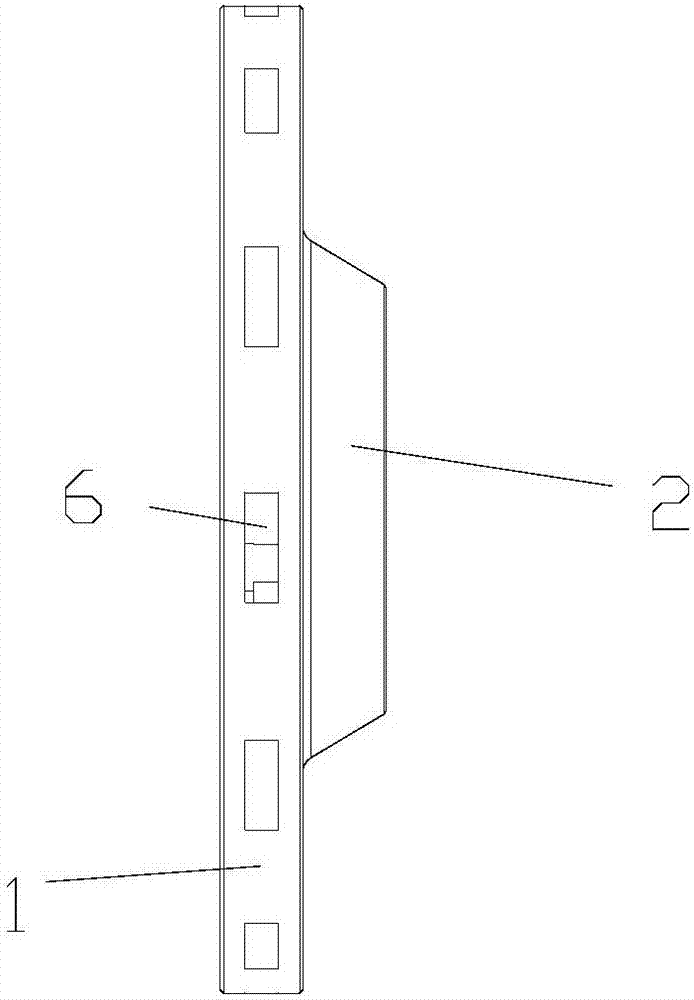

[0021] See attached figure 1 with attached figure 2 , the present embodiment includes a stamping-integrated brake main disc 1 and a brake sub-disc 2, the center of the brake main disc 1 is provided with a first circular opening, the diameter of the brake sub-disc 2 is equal to the diameter of the first circular opening, and the brake The edge of the bottom surface of the sub-disc 2 is connected to the circular opening, and the center of the brake sub-disc 2 is provided with a second circular opening 3; the main brake disc 1 is provided with a plurality of heat sinks 6 evenly and symmetrically distributed, and the main brake disc 1 is connected with the brake disc. The auxiliary disk 2 is provided with a plurality of luminous strips 4 made of silicate fluorescent powder. The brake sub-disc 2 is a conical structure with a narrow top and a wide bottom, and six screw holes 5 evenly and symmetrically distributed are arranged on the upper surface. The surface of the main brake di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com