Wear-proof rubber pipe

A wear-resistant rubber and hose technology, applied in the field of wear-resistant rubber hoses, can solve the problems of poor joint sealing, low structural strength and poor stability of rubber hoses, and achieve the effects of solving corrosion or wear, improving stability and reliability, and reasonable structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

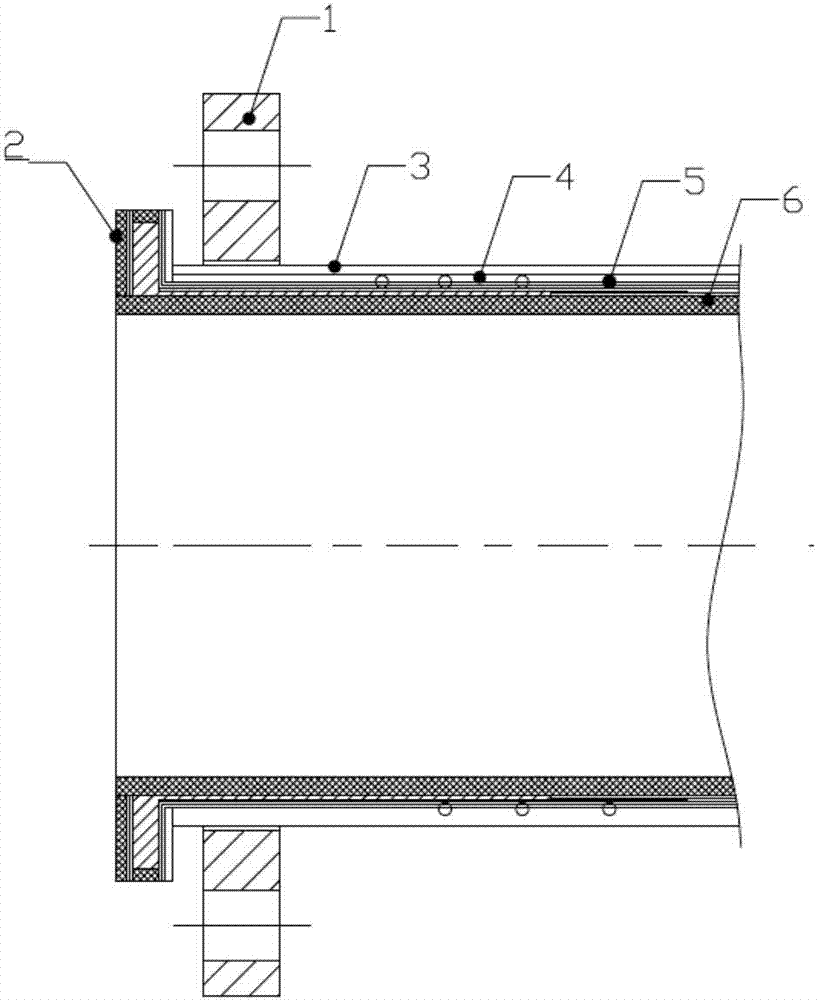

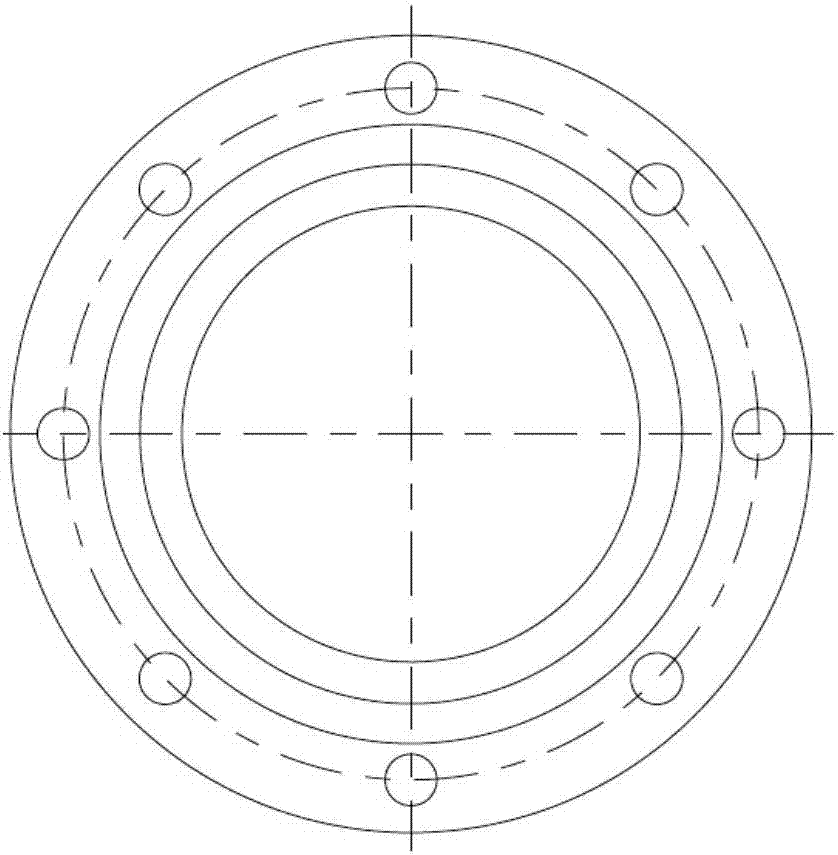

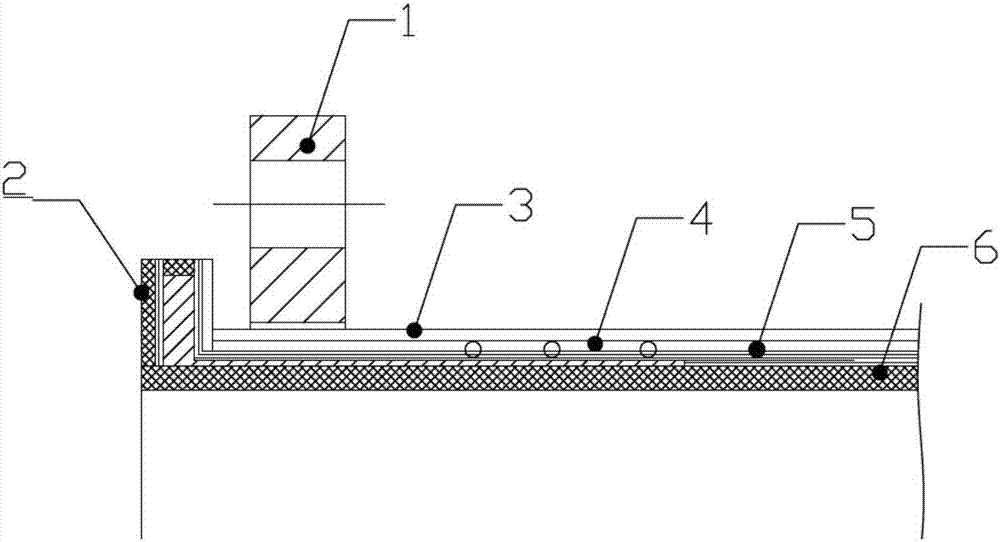

[0020] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

[0021] like Figure 1 to Figure 3 As shown, the wear-resistant rubber hose includes a rubber hose body and a flange at the end of the rubber hose body, wherein the rubber hose body is sequentially composed of working layer rubber 6, middle cord layer 5, bushing and steel wire 4 from the inner layer to the outer layer. As well as the weather-resistant adhesive 3 on the outer layer of the tube, the multi-layer integration greatly increases the strength of the hose.

[0022] The working layer of the inner layer is wear-resistant rubber, and the weather-resistant rubber of the outer layer of the pipe is a protective layer of corrosion-resistant rubber. The middle layer is an interlayer and a steel wire layer formed by cross winding of the cord fabric.

[0023] The rubber hose body is made of mult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com