Hair dyeing method based on surface coating principle

A technology of hair dyeing and surface coating, applied in the field of hair dyeing, which can solve the problems of failure to provide safety and non-irritation, failure to enter, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

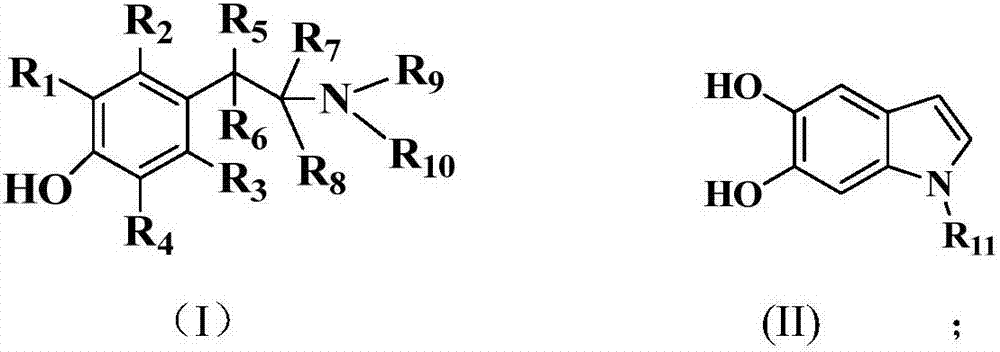

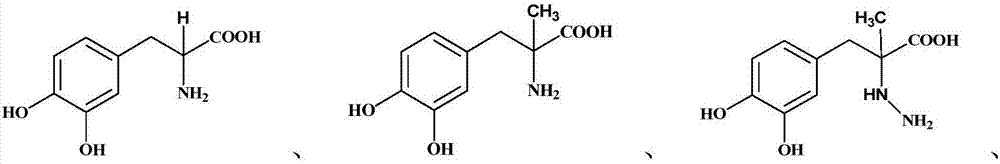

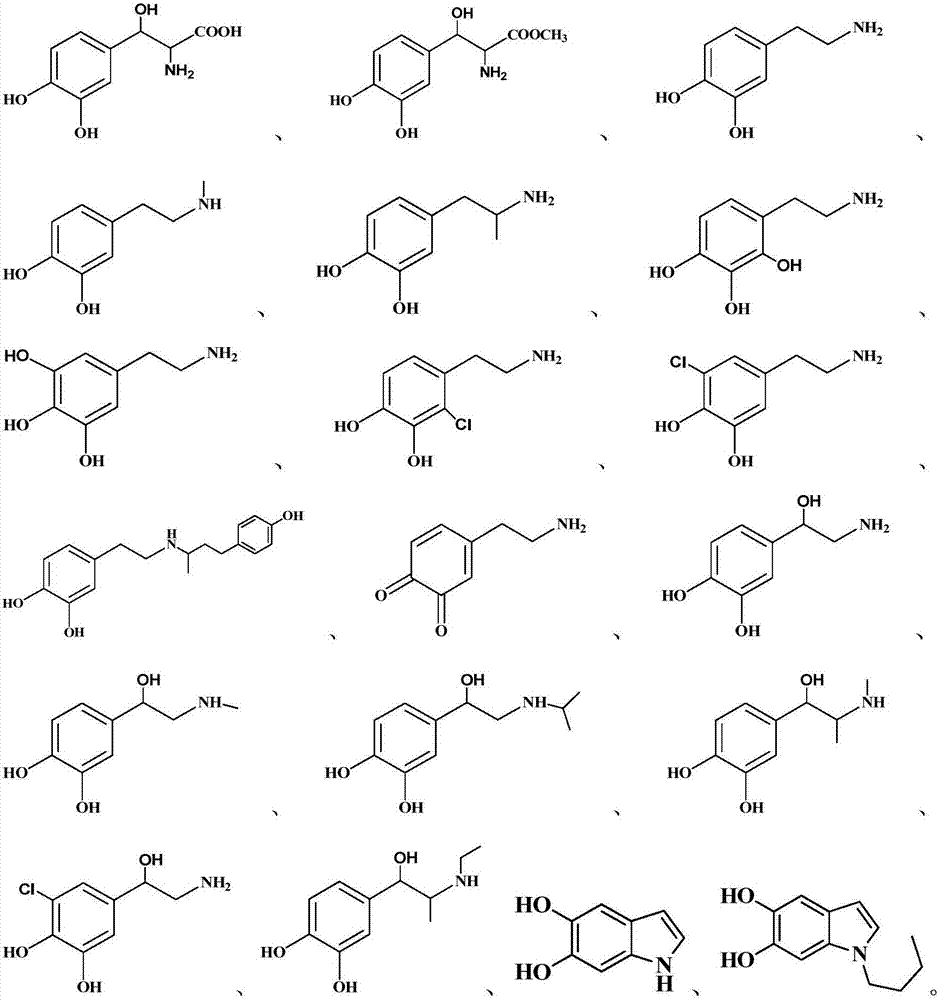

Method used

Image

Examples

Embodiment 1

[0050] A hair dyeing method based on the principle of surface coating, the concrete steps are as follows:

[0051] (1) Preparation of pre-staining agent

[0052] Add a given quality of pre-dye and biocompatibility additives into deionized water, adjust the pH to 8.0, and stir evenly to obtain the pre-dye. The pre-dye is best prepared and used immediately. Months, if the color becomes brown or black, it will be invalid; the components and their contents in the pre-staining agent are as follows:

[0053] Tris-HCl 0.1wt%, baking soda 0.2wt%, norepinephrine 0.5wt%, panthenol 0.5wt%, D-dopa 0.1wt%, olive oil 0.2wt%, the rest is deionized water;

[0054] (2) Preparation of dyeing agent

[0055] A given quality of coloring agent and corresponding additives are added to deionized water, and adjusted to pH = 8.0, and the coloring agent can be prepared after stirring evenly. The coloring agent can be stored for a long time under refrigerated conditions; each group in the coloring agen...

Embodiment 2

[0061] A hair dyeing method based on the principle of surface coating, the concrete steps are as follows:

[0062] (1) Preparation of pre-staining agent

[0063]Add a given quality of pre-dye and biocompatibility auxiliaries or just pre-dye into deionized water, adjust the pH to 5.8, and stir evenly to obtain the pre-dye. The pre-dye is best prepared and used immediately. It can be stored for half a month under the same conditions, and it will be invalid if the color turns brown or black; the components and their contents in the pre-staining agent are as follows:

[0064] Epinephrine (pre-dye) 0.2wt%, a-methyl dopamine 0.5wt%, L-dopa 10wt%, panthenol 0.5wt%, dopamine 0.1wt%, olive oil 0.2wt%, coconut oil 0.3wt%, glycerin 0.5wt%, squeezed lemon juice 0.5wt%, cornstarch 0.8wt%, konjac flour 0.1wt%, and the rest is deionized water;

[0065] (2) Preparation of dyeing agent

[0066] A coloring agent of a given quality and corresponding auxiliary agents are added to deionized wat...

Embodiment 3

[0072] A hair dyeing method based on the principle of surface coating, the concrete steps are as follows:

[0073] (1) Preparation of pre-staining agent

[0074] Add a given quality of pre-dye and biocompatibility auxiliaries or just pre-dye into deionized water, adjust the pH to 7.4, and stir evenly to obtain the pre-dye. The pre-dye is best prepared and used immediately. It can be stored for half a month under the same conditions, and it will be invalid if the color turns brown or black; the components and their contents in the pre-staining agent are as follows:

[0075] 5-Hydroxydopamine Hydrochloride 2wt%, Panthenol 0.5wt%, Coconut Oil 0.3wt%, Konjac Flour 0.1wt%, Carmellose Sodium 0.1wt%, Xanthan Gum 0.2wt%, the rest is phosphate buffer solution (PBS);

[0076] (2) Preparation of dyeing agent

[0077] A given quality of coloring agent and corresponding additives are added to deionized water, and adjusted to pH = 7.4, and the coloring agent can be prepared after stirrin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap