Novel sieving and crushing device for rare earth carbonate

A crushing device and rare earth carbonate technology, which is applied in the fields of sieving, solid separation, transportation and packaging, can solve problems such as unfavorable production and development of enterprises, waste of resources of enterprises, troublesome maintenance and repair, etc., to achieve safe and reliable performance, maintenance and repair. Easy and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

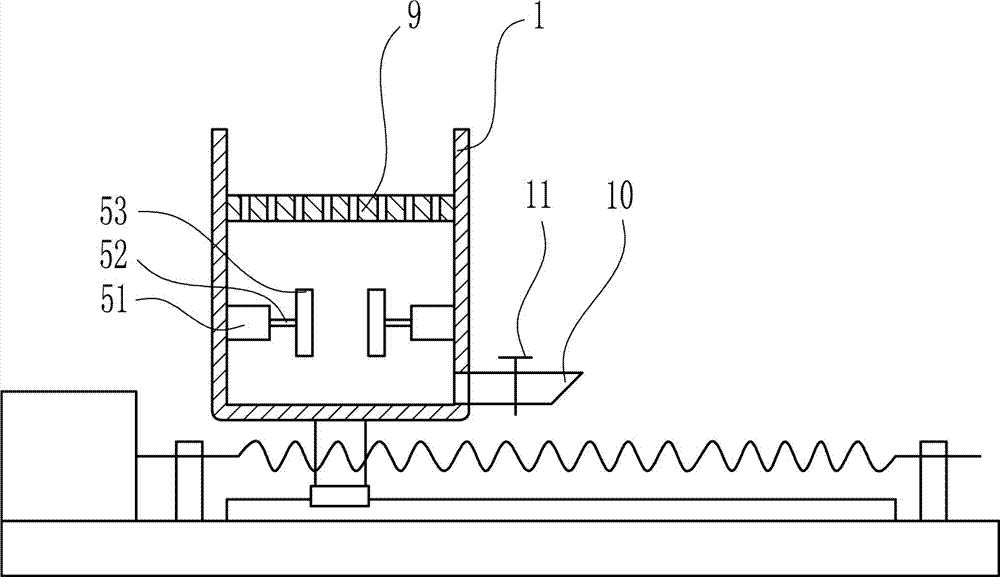

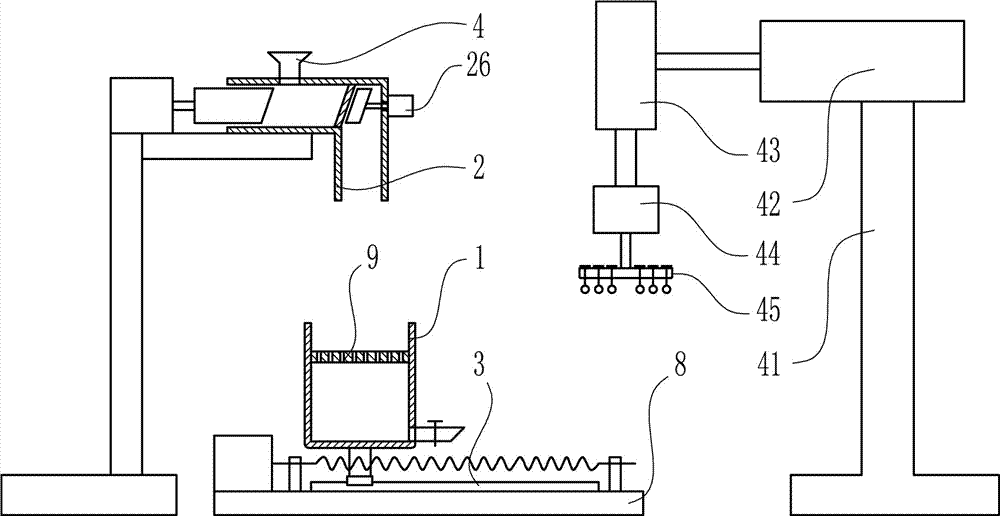

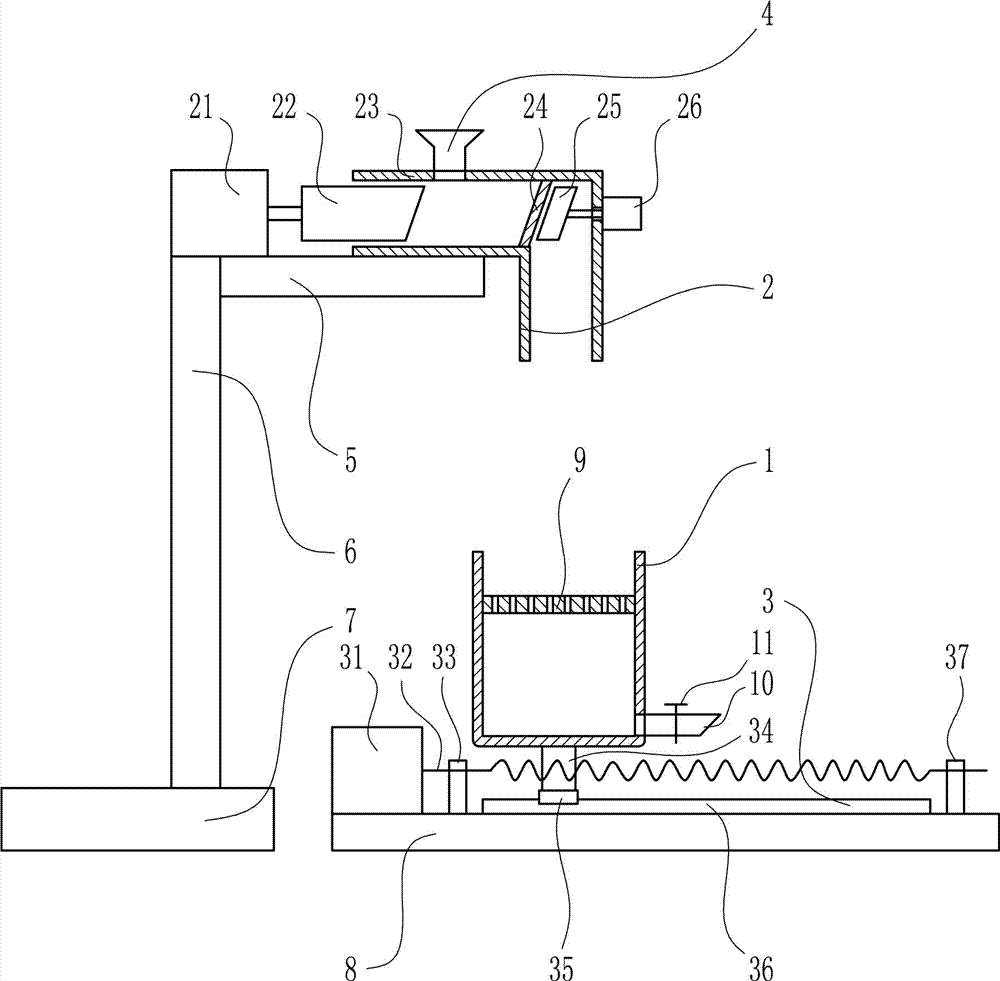

[0028] A new screening and crushing device for rare earth carbonate, such as Figure 1-4 As shown, it includes a cylinder body 1, a feeding device 2, a left and right shaking device 3, a hopper 4, a fixed plate 5, a connecting rod 6, a base I7, a base II 8, a large filter plate 9, a discharge pipe 10 and a valve 11; A feeding device 2 is arranged above the body 1, a left and right shaking device 3 is arranged below the cylinder body 1, a hopper 4 is arranged above the feeding device 2, a fixed plate 5 is arranged below the feeding device 2, and the left end of the fixed plate 5 is connected to the The upper end of the right side wall of the connecting rod 6 is connected by welding, the lower end of the connecting rod 6 is connected to the top of the base I7 by welding, and a base II8 is arranged on the right side of the base I7, and the base II8 is arranged on the side of the left and right shaking device 3 Below, the large filter plate 9 is connected to the inner side wall of...

Embodiment 2

[0030] A new screening and crushing device for rare earth carbonate, such as Figure 1-4 As shown, it includes a cylinder body 1, a feeding device 2, a left and right shaking device 3, a hopper 4, a fixed plate 5, a connecting rod 6, a base I7, a base II 8, a large filter plate 9, a discharge pipe 10 and a valve 11; A feeding device 2 is arranged above the body 1, a left and right shaking device 3 is arranged below the cylinder body 1, a hopper 4 is arranged above the feeding device 2, a fixed plate 5 is arranged below the feeding device 2, and the left end of the fixed plate 5 is connected to the The upper end of the right side wall of the connecting rod 6 is connected by welding, the lower end of the connecting rod 6 is connected to the top of the base I7 by welding, and a base II8 is arranged on the right side of the base I7, and the base II8 is arranged on the side of the left and right shaking device 3 Below, the large filter plate 9 is connected to the inner side wall of...

Embodiment 3

[0033] A new screening and crushing device for rare earth carbonate, such as Figure 1-4 As shown, it includes a cylinder body 1, a feeding device 2, a left and right shaking device 3, a hopper 4, a fixed plate 5, a connecting rod 6, a base I7, a base II 8, a large filter plate 9, a discharge pipe 10 and a valve 11; A feeding device 2 is arranged above the body 1, a left and right shaking device 3 is arranged below the cylinder body 1, a hopper 4 is arranged above the feeding device 2, a fixed plate 5 is arranged below the feeding device 2, and the left end of the fixed plate 5 is connected to the The upper end of the right side wall of the connecting rod 6 is connected by welding, the lower end of the connecting rod 6 is connected to the top of the base I7 by welding, and a base II8 is arranged on the right side of the base I7, and the base II8 is arranged on the side of the left and right shaking device 3 Below, the large filter plate 9 is connected to the inner side wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com