Method and system for controlling fluid quantitative output through vision

A fluid and visual technology, applied to the surface coating liquid device, spray device, coating, etc., can solve the problem of not being able to judge the quality of spray glue in real time, and achieve the effect of improving efficiency and quality, and accurately controlling flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

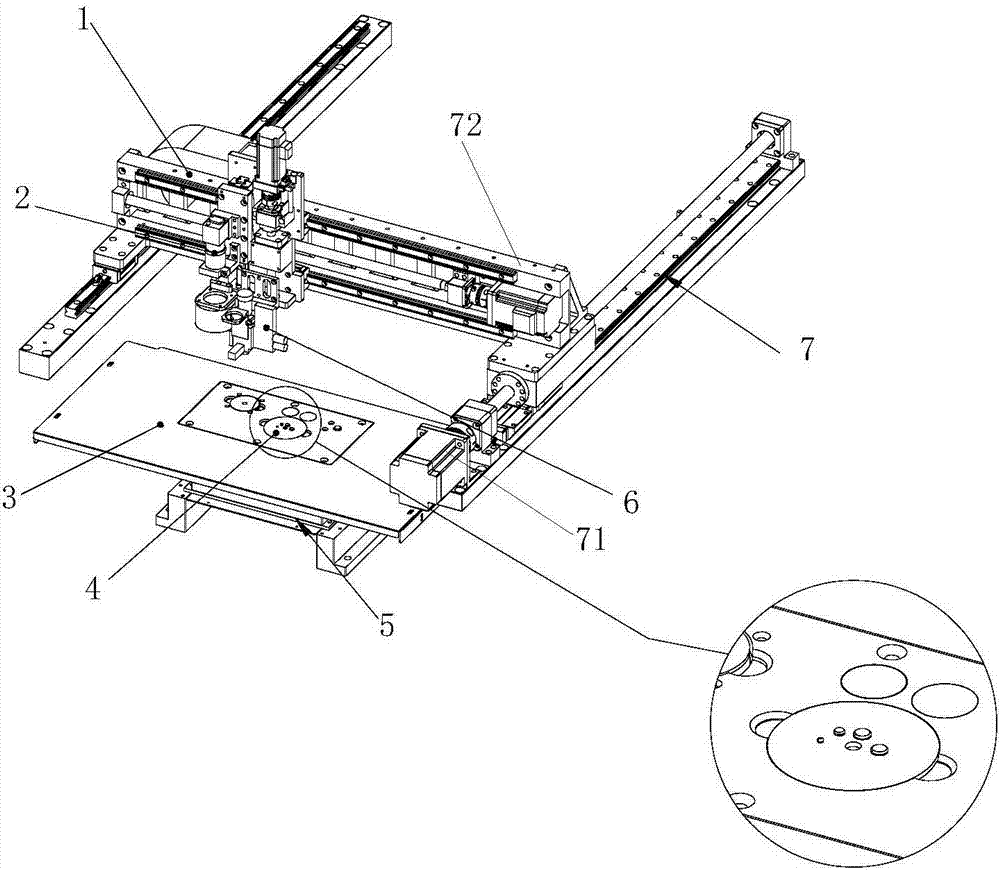

[0022] A method for visually controlling the quantitative output of fluid is provided, comprising the following steps:

[0023] A1. Establish a dispensing model database:

[0024] Through the precise quality calibration platform, different shapes of glue are sprayed according to different production processes;

[0025] Collect weight data through digital communication protocols (Rs232, RS-485, MODBUS, TCP / IP), and save weight data records of different shapes of glue into the database;

[0026] Move the optical camera to the area of the precision quality calibration platform, take images, and build image templates for glues of different shapes in sequence; establish correspondence between image templates and weight data of glues of different shapes to establish a model database, and automatically generate weight and specifications for the shape of glue , shape and other quality parameters;

[0027] The above steps are the steps of optical calibration of the amount of glue; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com