A fixed-point gluing device for wooden boards at equal intervals

A gluing device and equidistant technology, which is applied in the field of plate processing, can solve the problems of low efficiency and inability to carry out equidistant fixed-point spraying, etc., and achieve good gluing effect, high gluing efficiency and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

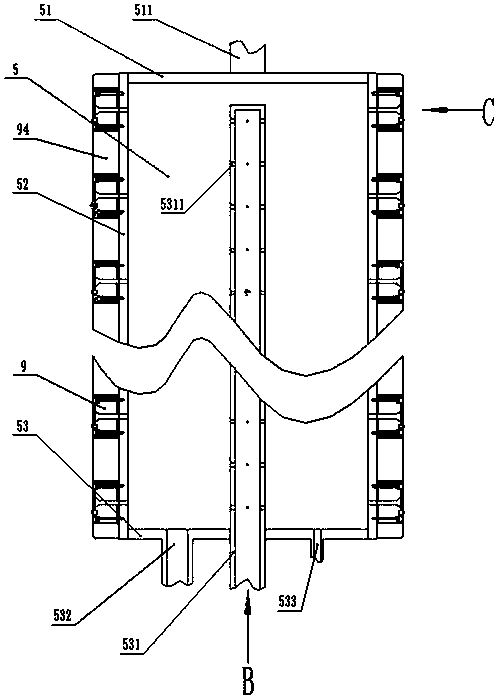

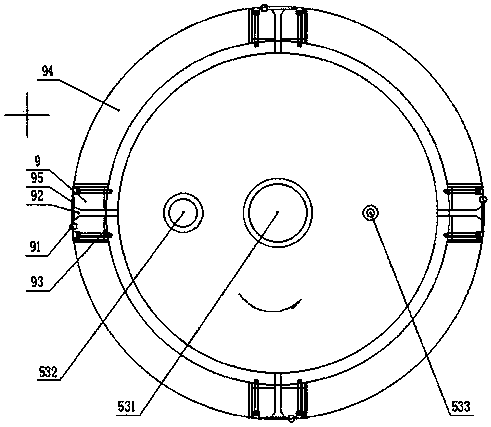

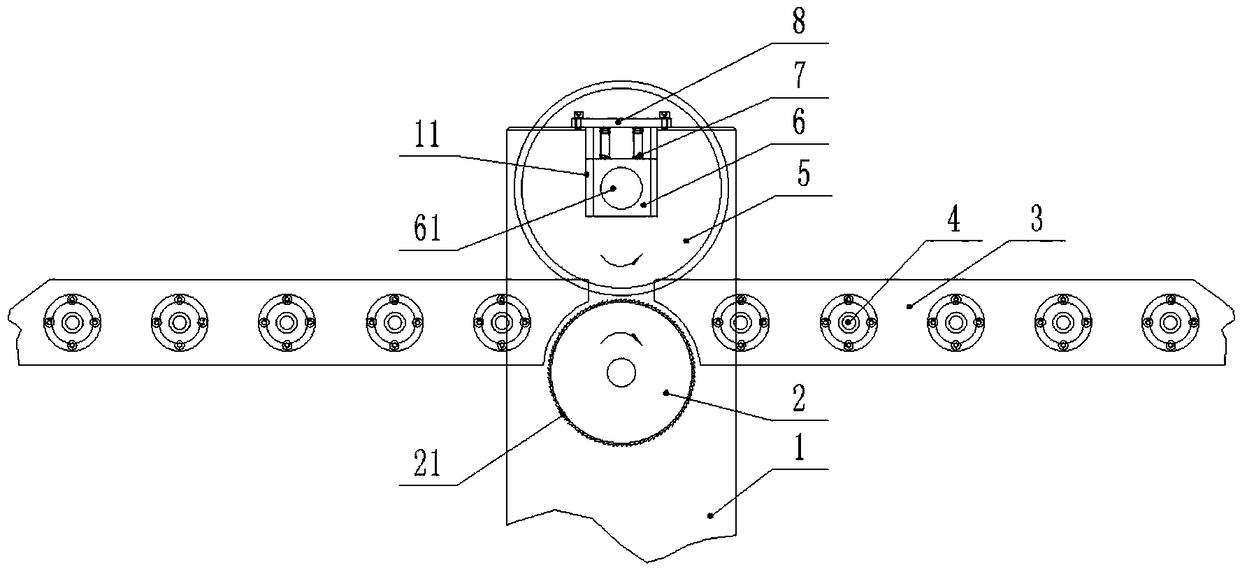

[0027] As shown in the figure, a wood board equidistant fixed-point gluing device described in the embodiment of the present invention includes: figure 1 , figure 2 As shown, two side plates 1 are symmetrically fixed, and the top of the side plate 1 is processed with a slideway 11, and the upper end of the slideway 11 is a cover plate 8 fixed on the side plate 1; the slider 6 is movably installed in the slideway 11 , the center of the slider 6 is processed with a mounting hole 61, and the pressure spring 7 is connected between the slider 6 and the cover plate 8; as Figure 4 , Figure 5 As shown, the glue injection barrel 5 is movably installed in the installation hole 61. The glue injection barrel 5 includes an inner cover 51, a barrel body 52, and an outer cover 53. A solid shaft 511 is fixedly installed at the center of the inner cover 51, and the center of the outer cover 53 The hollow tube 531 is fixedly installed, and the hollow tube 531 extends into the barrel body 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com