Tool capable of being replaced easily

A tool and tool handle technology, applied in the field of easy-to-change tools, can solve problems such as wasting time, being incompetent for ordinary workers, increasing production and processing time, and achieving the effects of improving replacement time, easy replacement, and simplified installation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

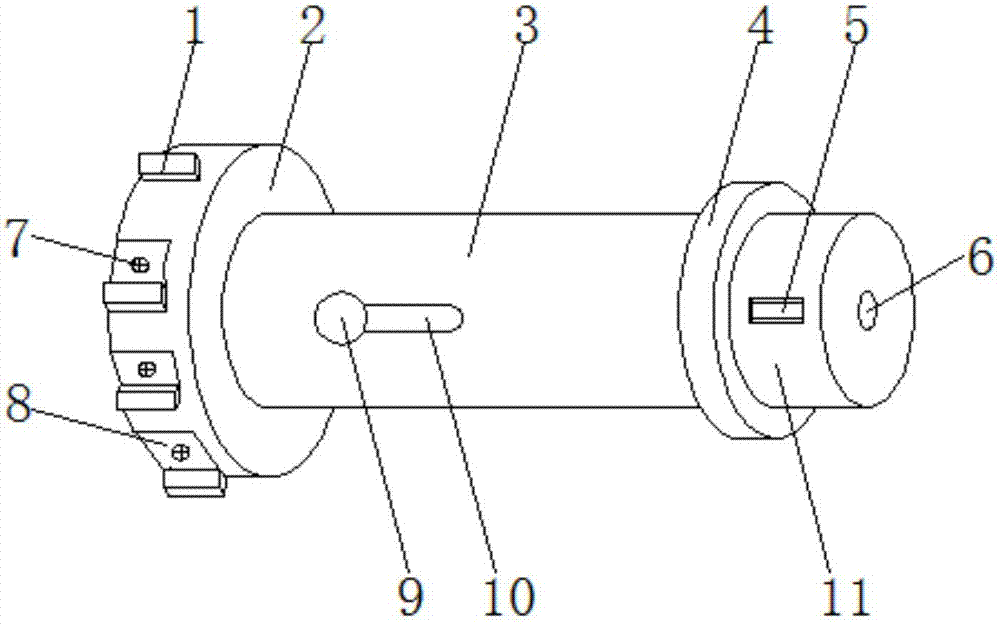

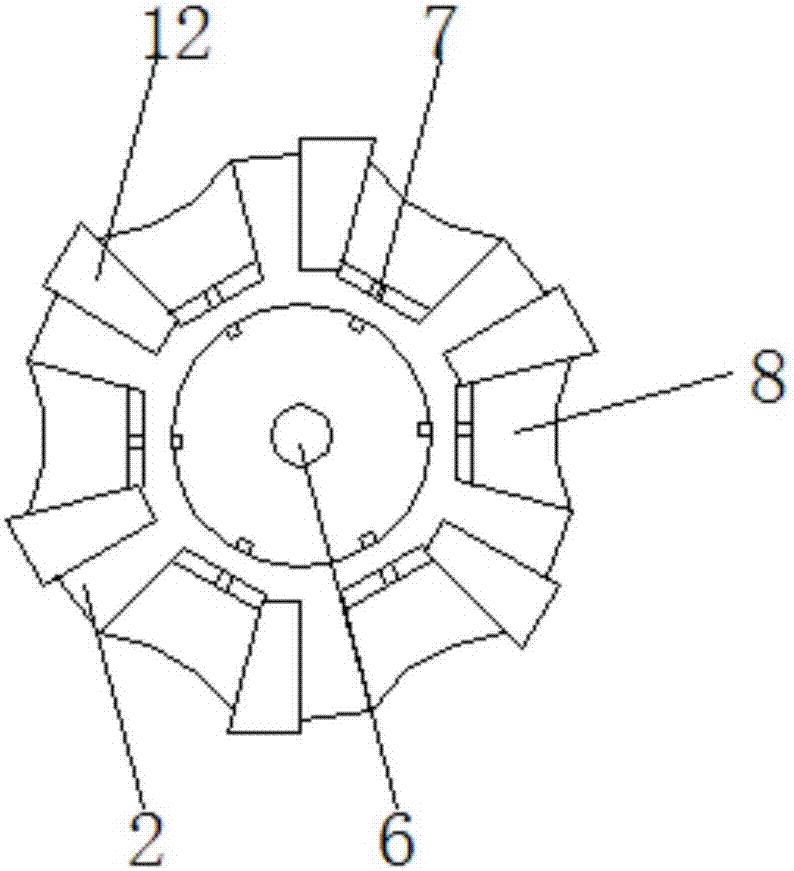

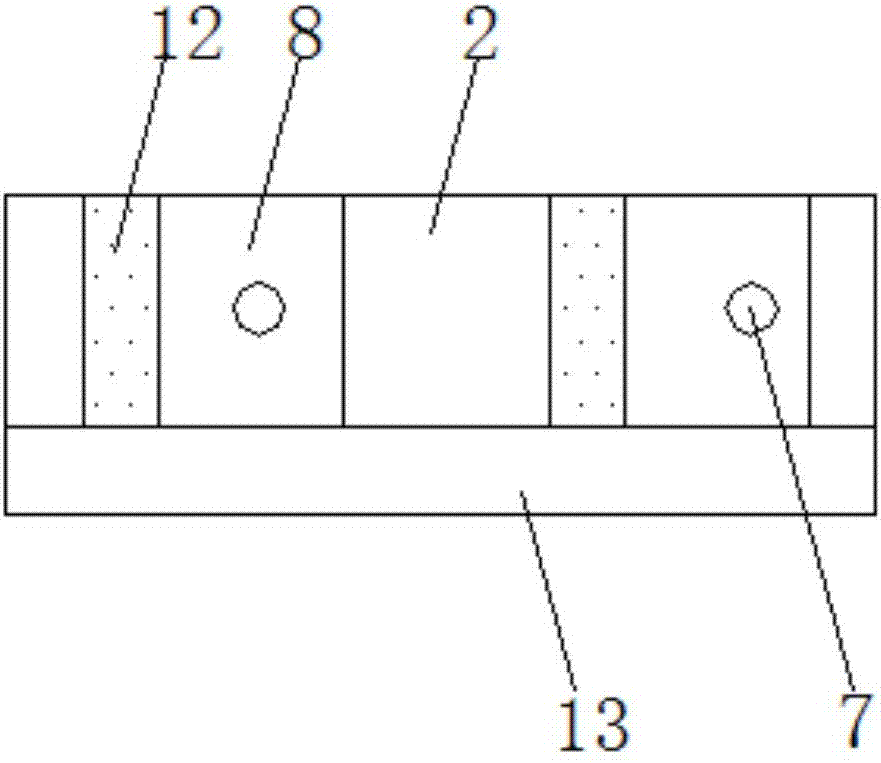

[0024] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0025] A kind of tool that is easy to replace of the present invention, in its preferred embodiment, please refer to Figure 1-7 As shown, the easy-to-replace tool includes a handle 3, a connecting shaft 11, and a slot 18. The right side of the handle 3 is connected to the connecting shaft 11, and a shaft is fixed at the joint between the handle 3 and the connecting shaft 11. The shoulder 4, the side of the connecting shaft 11 is provided with a keyway 5, the inside of the handle 3 is provided with a second pin hole 19, and there are two second pin holes 19, the second pin hole 19 is equipped with a pin shaft 16, and the pin shaft 16 The right end is fixed with a spring 20, and the spring 20 is arranged at the right end inside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com