Portable abrasive jet cutting device

A technology of abrasive jet cutting and abrasive jet, applied in the direction of abrasive feeding device, used abrasive processing device, abrasive jet machine tool, etc., can solve the problems of uneven suction of abrasive, small overall weight, poor reliability of abrasive, etc. Achieve the effects of small overall weight, good cutting effect and reliable overload protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

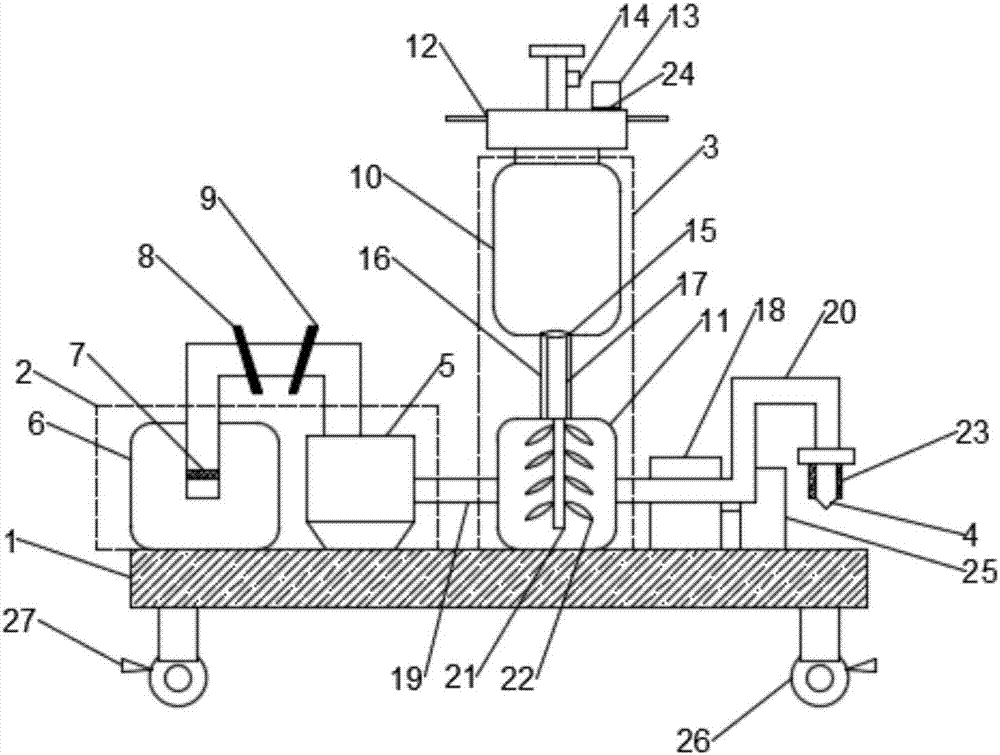

[0017] Such as figure 1 As shown, the present invention provides a portable abrasive jet cutting device, including a base 1, a plunger pump station 2, an abrasive jet generator 3 and a nozzle 4 are arranged above the base 1, and the plunger pump station 2 is used for Provide pressurized water to the whole working system. The plunger pump station 2 is composed of a plunger pump 5 and a water tank 6. The plunger pump 5 and the water tank 6 are connected together. There is a filter screen 7, the plunger pump 5 is provided with a safety valve 8 and a pressure regulating valve 9, the abrasive jet generating device 3 includes an abrasive tank 10 and a mixing tank 11, and the abrasive tank 10 is a cylindrical pressure vessel , the top of the abrasive tank 10 is provided with a screw cap 12 and a piston 13, the screw cover 12 is provided with a pressure relief valve 14, the bottom of the abrasive tank 10 is provided with a discharge port 15, and the mixing tank 11 is provided with Be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com