Replacement device of horizontal type looping car steering rope sheave

A technology of looper and rope wheel, which is applied in the field of devices for quickly changing the steering rope wheel of horizontal looper, which can solve problems affecting normal production and achieve the effects of ensuring smooth progress, reducing labor intensity, and improving replacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

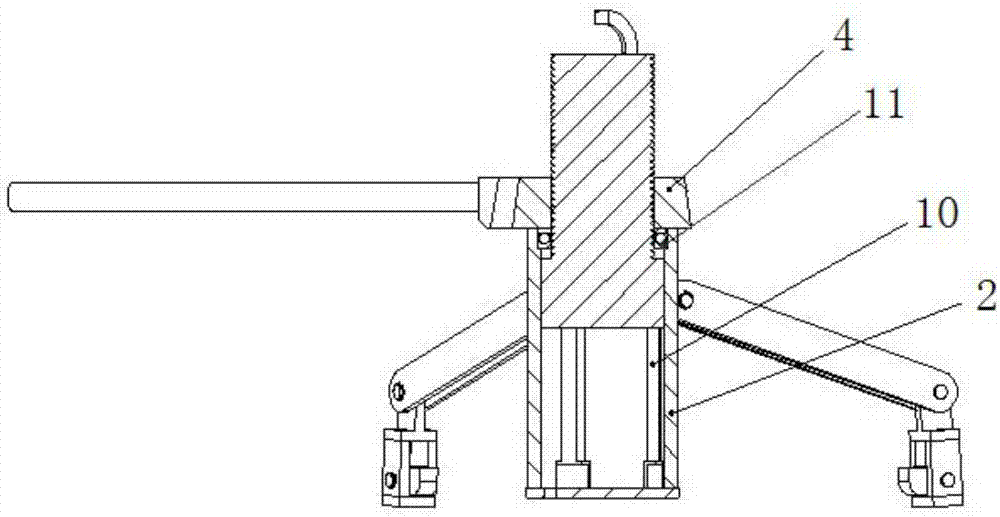

[0023] The invention provides a device capable of quickly replacing the steering sheave. The device uses the principle of screw transmission to convert rotary motion into linear motion. The mechanism runs smoothly and can transmit large axial force. It also has a self-locking function. The size of the device can be determined according to the size of the space where the steering sheave is located.

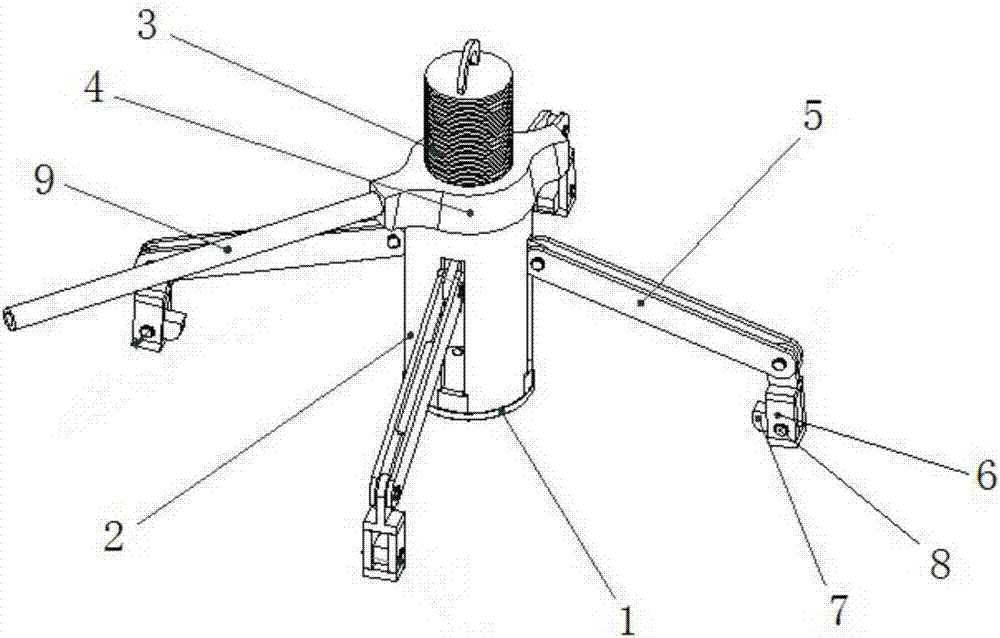

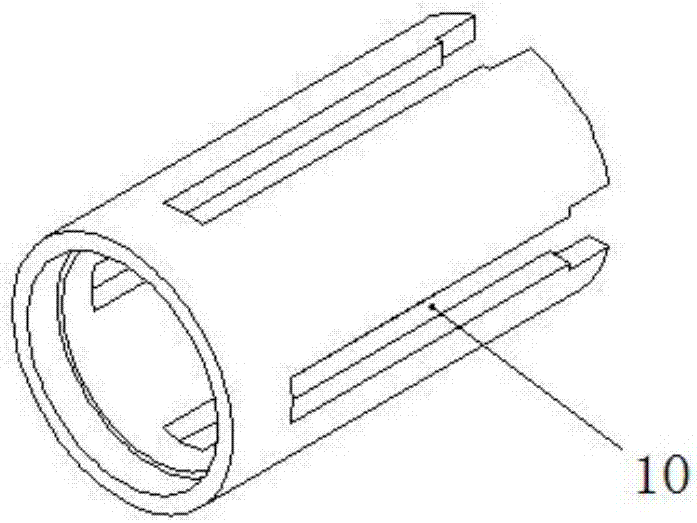

[0024] see Figure 1 to Figure 10 , the present invention mainly includes a base 1, a sleeve 2, a lifting shaft 3, a rotating nut 4, a pull rod 5, a claw bracket 6, a claw 7, a pin 8, a torsion bar 9, and a thrust ball bearing 11. Wherein, three holes with a diameter of 17mm are evenly distributed on the base 1, which can be fixed on the axle 14 of the steering sheave 13 through M16 bolt connection. The upper surface of the base 1 is welded with four clamping platforms 16 distributed along the circumferential direction for limiting the rotation of the sleeve 2 . The lower end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com