Driver Torque Demand Analysis Method for Hybrid Electric Vehicles

A hybrid electric vehicle and analytical method technology, applied in the field of electric vehicle vehicle control, can solve the problems of reduced motor output power, regardless of the torque capacity of the power system, inconsistent intentions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

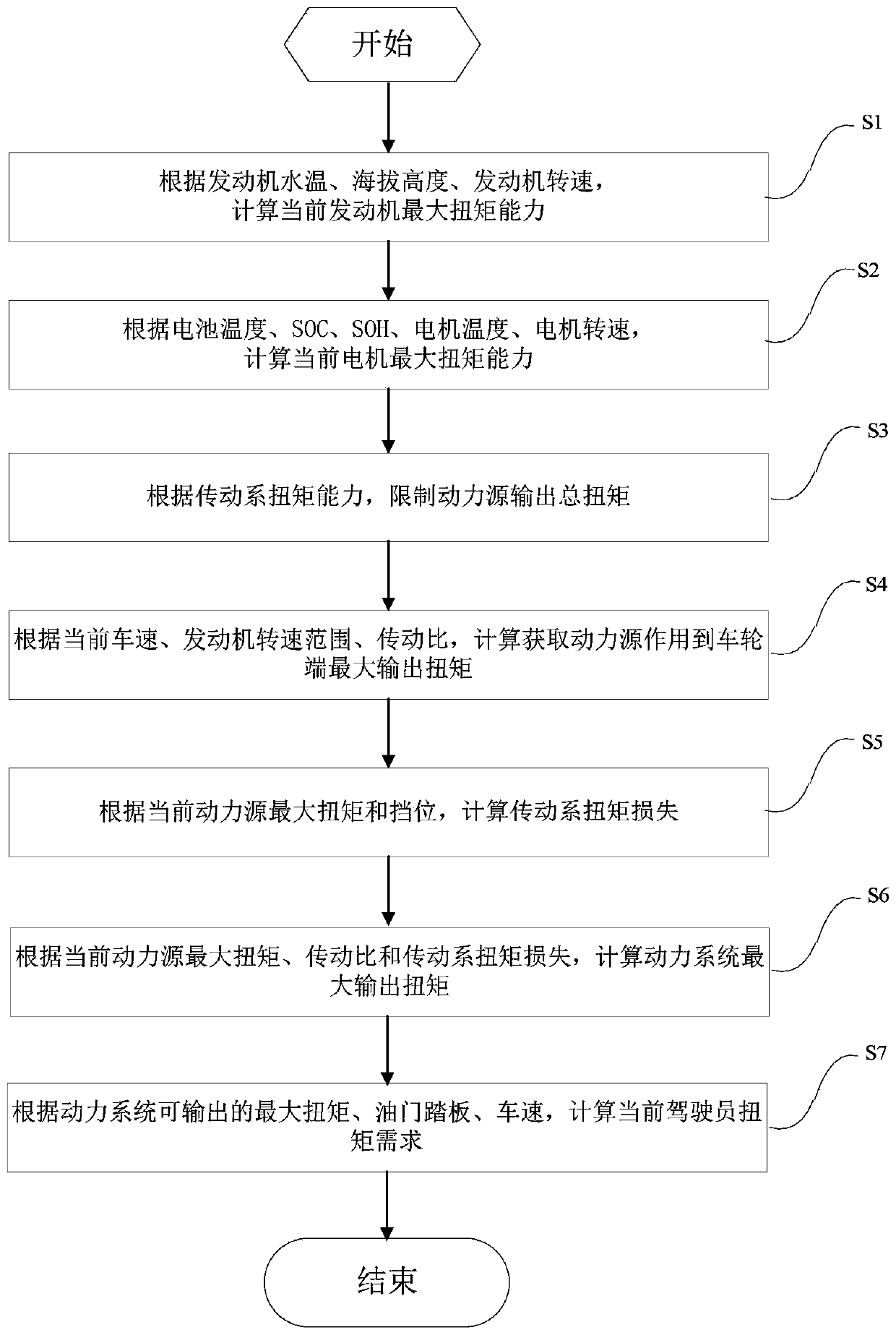

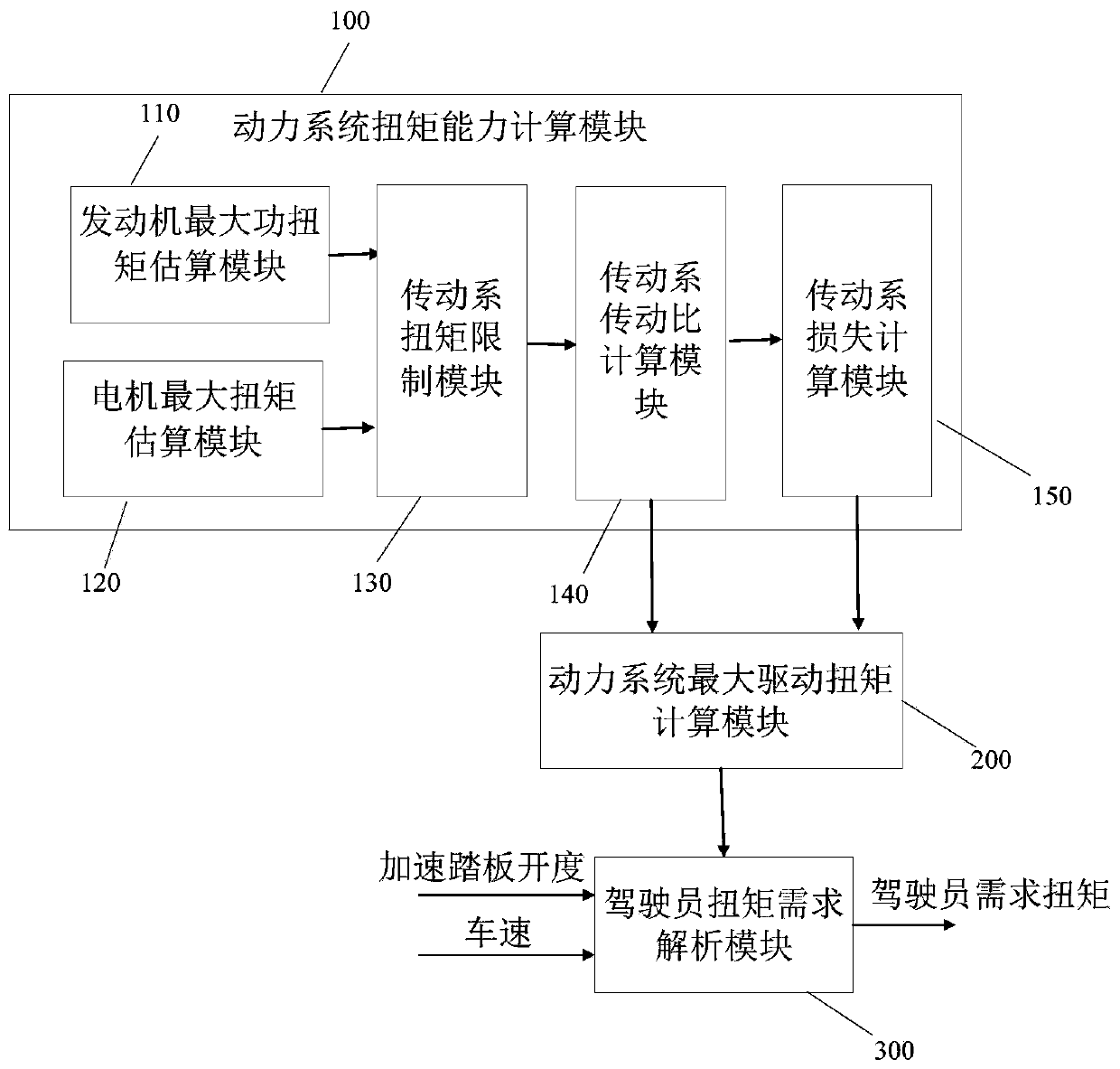

[0025] The invention provides a torque demand analysis method for a driver of a hybrid electric vehicle to solve the problem that the actual output torque of the vehicle does not match the driver's intention when the torque capacity of the existing power system changes.

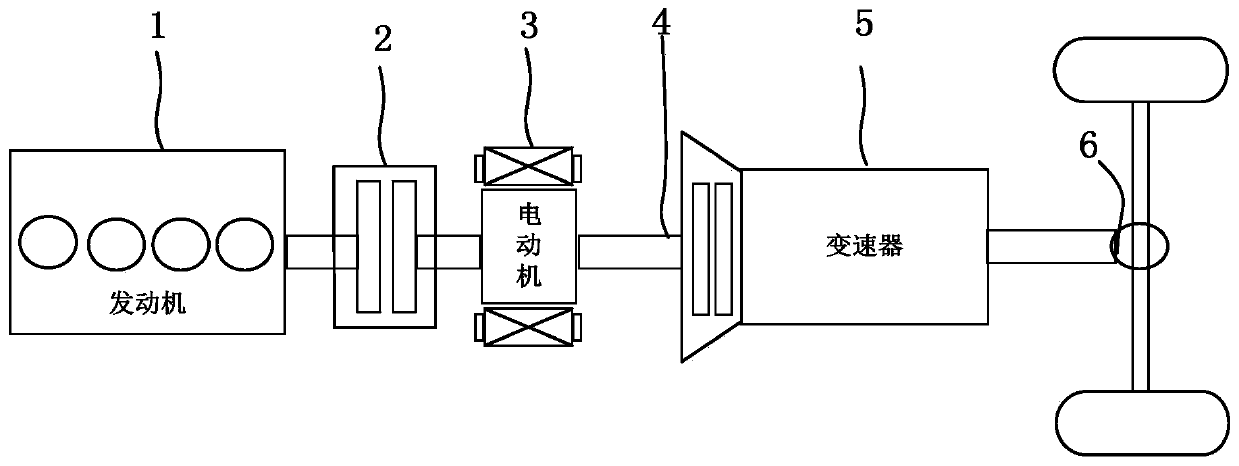

[0026] The invention discloses a method for analyzing driver's torque demand of a hybrid electric vehicle. The hybrid electric vehicle includes assembly components such as an engine, a drive motor, a transmission, and a high-voltage battery. Requirements analysis method.

[0027] The calculation method of the torque capacity of the power system is based on the current torque capacity of the engine, the current torque capacity of the motor, the transmission ratio of the transmission system, the loss of the transmission system and the torque capacity of the transmission system, and calculates the maximum driving torque that the power source acts on the drive wheel end. When the current torque of the engine When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com