Ramie blended yarn and processing method, system and application of ramie blended yarn

A blended yarn and processing method technology, which is applied in the field of spinning, can solve the problems of low processing efficiency, inability to achieve high ramie blended ratio yarn spinning, and low yarn quality of ramie cotton blended yarn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

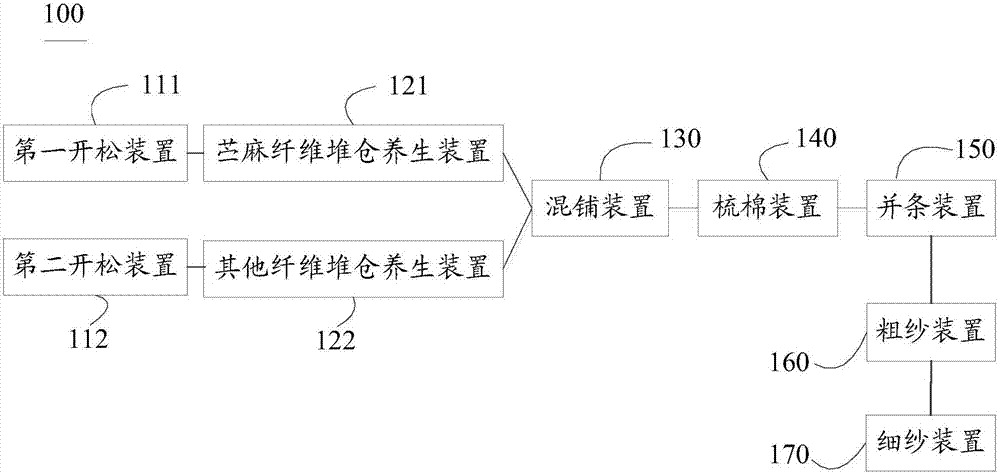

[0067] Adopt ramie blended yarn processing system 100, ramie fiber is carried out opening treatment in the first opening device 111, then is placed in ramie fiber storage bin health-preserving device 121, softening agent monoalkyl dimethyl tertiary amine is sprayed on through opening device 111 The processed ramie fibers were loosened, then mixed and stacked and placed under 45°C for 50 hours with a tarpaulin cover to obtain refined ramie fibers. The refined ramie fiber is cleaned in the first cleaning device. The weight ratio of the softener to the opened ramie fiber is 14:100.

[0068] The cotton fibers are opened in the second opening device 112, and then placed in other fiber storage bin health care devices 122, and the sugar-removing agent is sprayed on the cotton fibers after the opening treatment, and then they are mixed in the storage bin and used in the awning Put the top of the cloth cover at 28°C for 32 hours, and then place it in the second cleaning device for cle...

Embodiment 2

[0072] Using the ramie blended yarn processing system 100, the ramie fibers are opened in the first opening device 111, and then placed in the ramie fiber stacking storage device 121, and the softening agent trialkyl tertiary amine is sprayed on the ramie fiber after the opening treatment. The ramie fibers were mixed and stacked and placed under a tarpaulin cover at 50°C for 24 hours to obtain refined ramie fibers. The refined ramie fiber is cleaned in the first cleaning device. The weight ratio of the softener to the opened ramie fiber is 10:100.

[0073] The bamboo fibers are opened in the second opening device 112.

[0074] The refined ramie fibers after the cleaning treatment and the bamboo fibers after the opening treatment are mixed in the mixing device 130 according to the weight ratio of 55:45, and they are mixed under the vibration of the vibrating device to form a fiber web.

[0075] The fiber web is carded in the carding device 140 to produce a mixed sliver. The ...

Embodiment 3

[0077] Using the ramie blended yarn processing system 100, the ramie fibers are opened in the first opening device 111, and then placed in the ramie fiber stacking storage device 121, and the softening agent trialkyl tertiary amine is sprayed on the ramie fiber after the opening treatment. The ramie fibers were mixed and stacked and placed under a tarpaulin cover at 25°C for 96 hours to obtain refined ramie fibers. The refined ramie fiber is cleaned in the first cleaning device. The weight ratio of the softener to the opened ramie fiber is 15:100.

[0078] The polyester fibers are opened in the second opening device 112 .

[0079] The refined ramie fiber after the cleaning treatment and the polyester fiber after the opening treatment are mixed in the mixing and laying device 130 according to the weight ratio of 55:45, and they are mixed under the vibration of the vibrating device to form a fiber web.

[0080] The fiber web is carded in the carding device 140 to produce a mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com