Environment-friendly chlorite bleaching stabilizer as well as preparation method and application thereof

A stabilizer and sub-bleaching technology, which is applied in the field of environmental protection sub-bleaching stabilizer and its preparation, can solve the problems of high material and labor protection requirements, non-compliance with environmental protection, and damage to workers' health, so as to improve yarn quality and utilization rate , reduce the escape rate, reduce the effect of decomposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

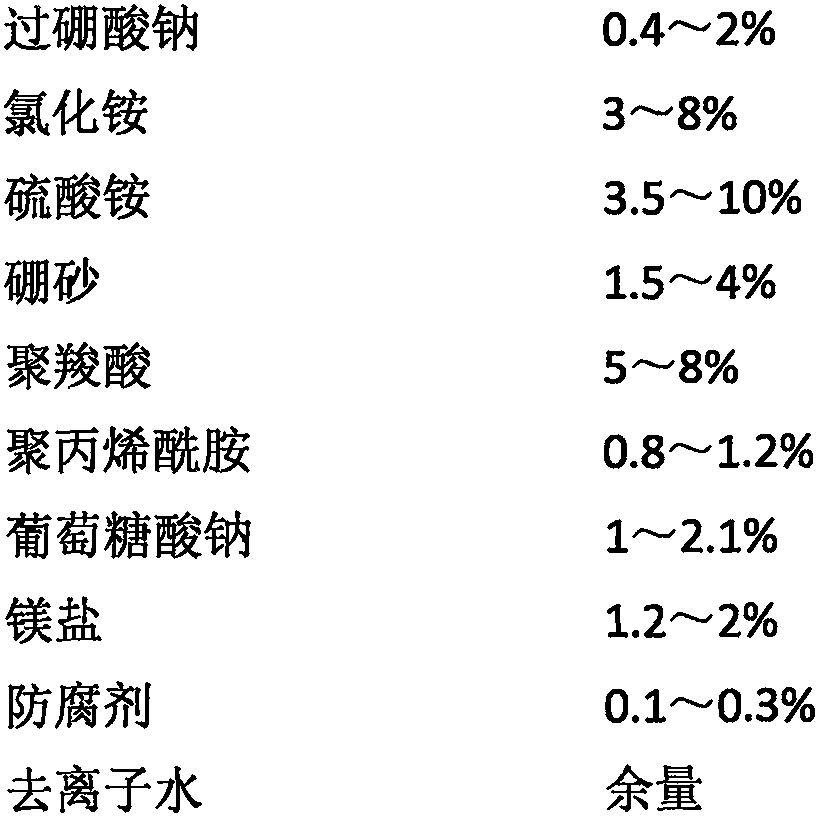

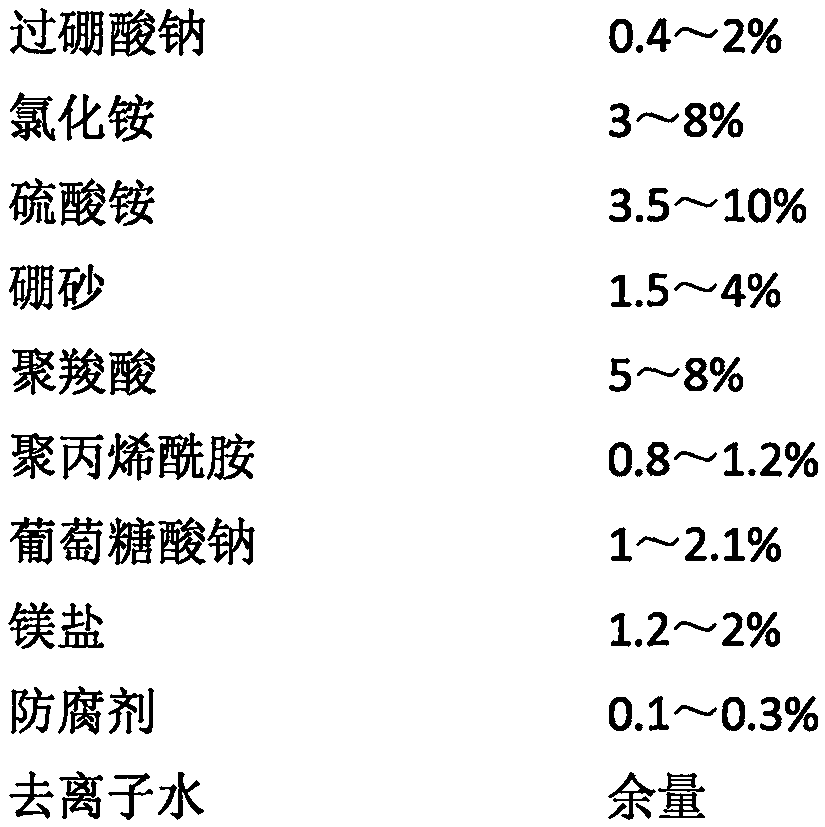

[0025] A kind of preparation method of environment-friendly sub-bleach stabilizer is characterized in that, comprises the steps:

[0026] S10, add quantitative deionized water to the stirring tank I, start stirring, add 0.8% polyacrylamide, fully dissolve until completely transparent and set aside;

[0027] S20, add quantitative deionized water to the stirring tank II, start stirring, add 3.5% of ammonium sulfate, 8% of ammonium chloride, 1.6% of sodium gluconate, 1.4% of magnesium salt, and 6% of polycarboxylic acid in turn, and put The polyacrylamide solution in the reaction kettle 1 is added and stirred evenly;

[0028] S30, add borax 1.5%, sodium perborate 2%, stir and dissolve evenly;

[0029] S40, add preservative 0.2% and stir for 10 minutes, the solution is uniform and transparent in appearance, add water to the specified volume, filter and discharge.

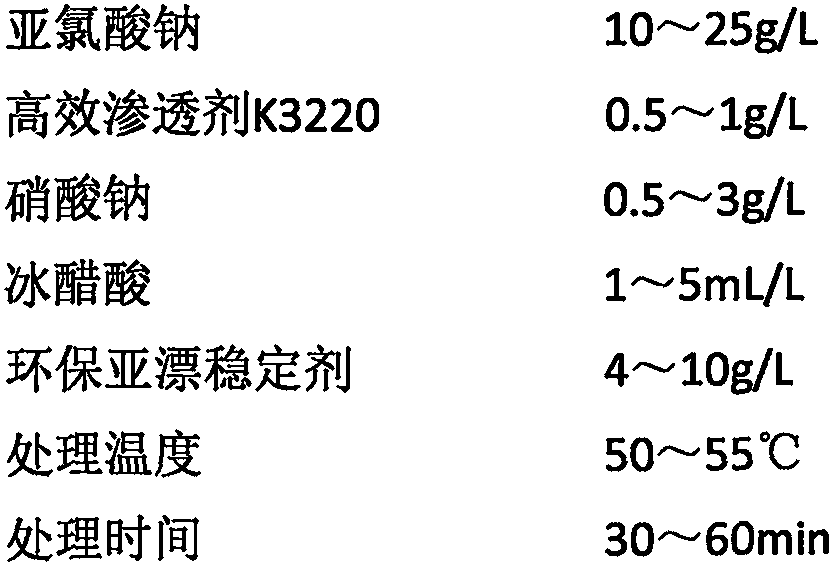

[0030] In the present embodiment, the process formula of the environmentally friendly sub-bleaching stabilizer used...

Embodiment 2

[0037] A kind of preparation method of environment-friendly sub-bleach stabilizer is characterized in that, comprises the steps:

[0038] S10, add quantitative deionized water to the stirring tank I, start stirring, add 1% polyacrylamide, fully dissolve until completely transparent and set aside;

[0039] S20, add quantitative deionized water to the stirring tank II, start stirring, add 5% ammonium sulfate, 7.5% ammonium chloride, 1.8% sodium gluconate, 1.6% magnesium salt, and 7% polycarboxylic acid in turn, and put The polyacrylamide solution in the reaction kettle 1 is added and stirred evenly;

[0040] S30, add borax 2%, sodium perborate 1.5%, stir and dissolve evenly;

[0041] S40, add 0.1% preservative and stir for 5 minutes, the solution is uniform and transparent in appearance, add water to the specified volume, filter and discharge.

[0042] In the present embodiment, the process formula of the environmentally friendly sub-bleaching stabilizer used in the degumming ...

Embodiment 3

[0045] A kind of preparation method of environment-friendly sub-bleach stabilizer is characterized in that, comprises the steps:

[0046] S10, add quantitative deionized water to the stirring tank I, start stirring, add 1.1% polyacrylamide, fully dissolve until completely transparent and set aside;

[0047] S20, add quantitative deionized water to the stirring tank II, start stirring, add 7% ammonium sulfate, 6% ammonium chloride, 1% sodium gluconate, 1.2% magnesium salt, and 5% polycarboxylic acid in turn, and put The polyacrylamide solution in the reaction kettle 1 is added and stirred evenly;

[0048] S30, add borax 2.5%, sodium perborate 1.2%, stir and dissolve evenly;

[0049] S40, add preservative 0.25% and stir for 8 minutes, the appearance of the solution is uniform and transparent, add water to the specified volume, filter and discharge.

[0050] In the present embodiment, the process formula of the environmentally friendly sub-bleaching stabilizer used in the degum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com