Dispersion method of nano carbon material

A nano-carbon material and dispersion technology, applied in the direction of nano-carbon, lignin coating, coating, etc., can solve the problems of lack of strong interaction, reduce the performance of carbon materials, and damage the carbon conjugated structure, so as to maintain the chemical structure and Functionality, strong pH buffering ability, the effect of strong pH buffering ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

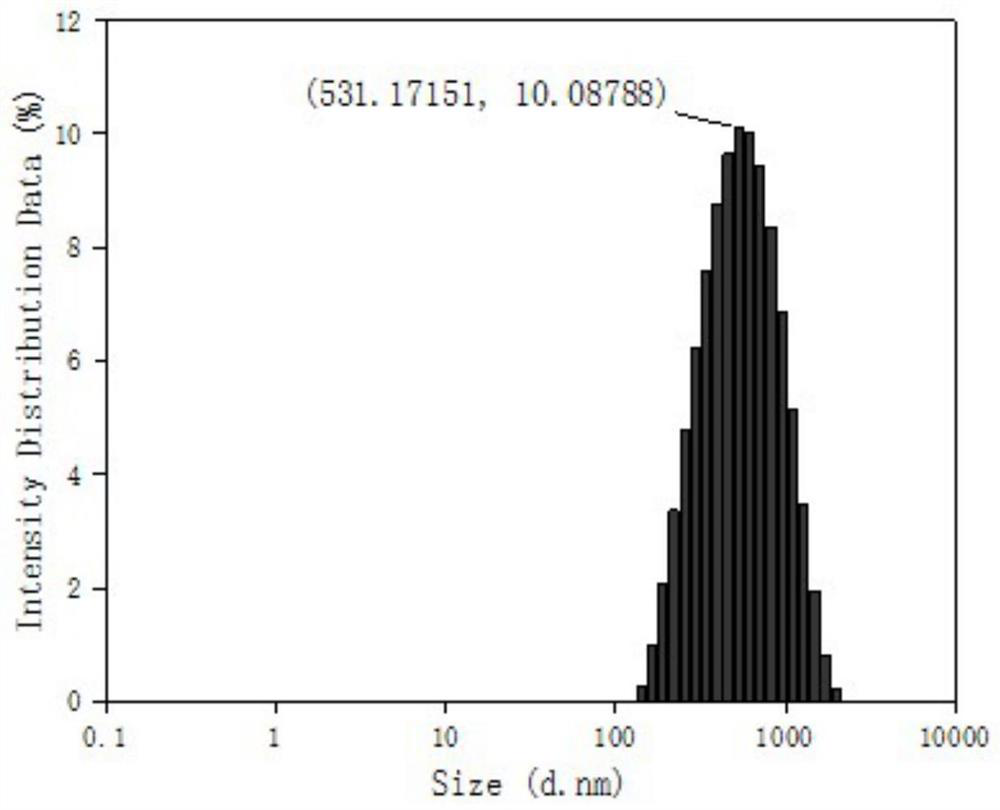

Embodiment 1

[0029] A method of utilizing tannic acid metal complexes to realize the dispersion and transfer of all kinds of nano-carbon materials, the specific steps are as follows:

[0030] (1) Tannic acid (TA) and FeCl 3 ·6H 2 O is added with ultrapure water to prepare respectively the molar concentration of 24mM tannic acid (TA) aqueous solution and 37mM FeCl 3 aqueous solution;

[0031] (2) get the 0.5mL tannic acid (TA) aqueous solution and 0.5mLFeCl that step (1) obtains 3 The aqueous solution was sequentially added to 49mL of ultrapure water to prepare TA / Fe Ⅲ complexes;

[0032] (3) adding graphene to ultrapure water to configure a mixed solution whose mass concentration is 0.1 mg / mL;

[0033] (4) Put the mixed solution of step (3) into an ultrasonic cell pulverizer under an ice-water bath and sonicate for 36 minutes;

[0034] (5) Add the TA / Fe prepared in step (2) to the mixed solution after ultrasonication in step (4) Ⅲ Complex compound (mass ratio: tannic acid: graphene=...

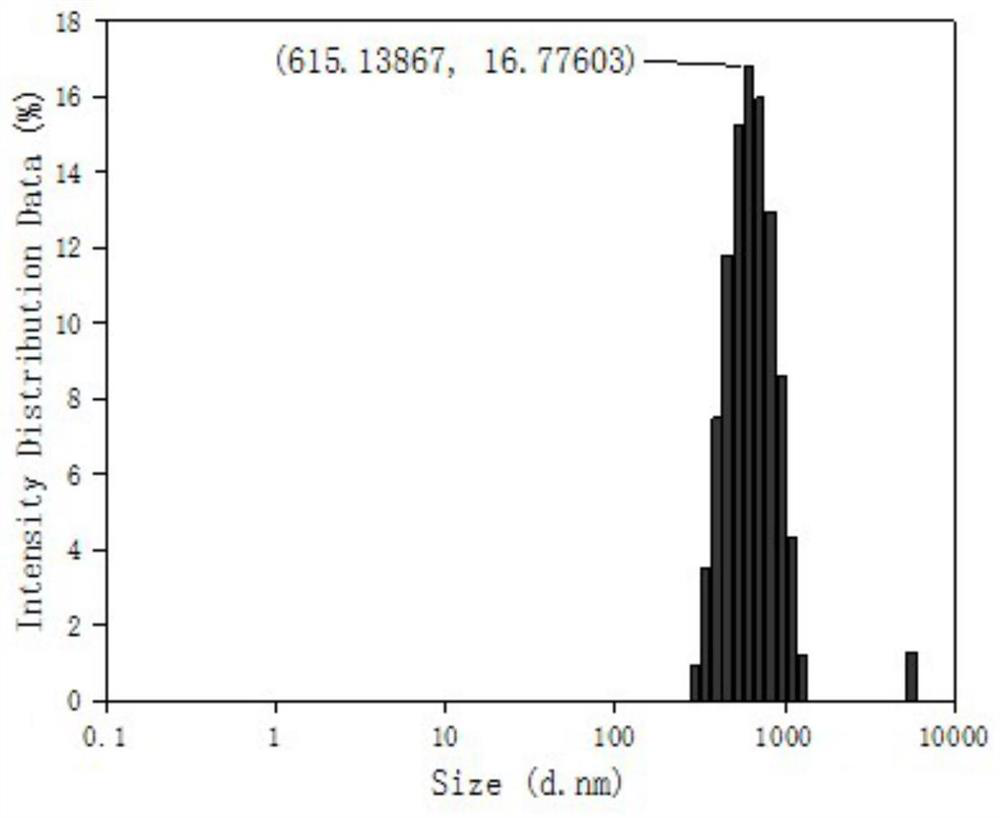

Embodiment 2

[0037] A method of utilizing tannic acid metal complexes to realize the dispersion and transfer of all kinds of nano-carbon materials, the specific steps are as follows:

[0038] (1) Tannic acid (TA) and FeCl 3 ·6H 2 O is added with ultrapure water to prepare respectively the molar concentration of 24mM tannic acid (TA) aqueous solution and 37mM FeCl 3 aqueous solution;

[0039] (2) get the 0.5mL tannic acid (TA) aqueous solution and 0.5mlFeCl that step (1) obtains 3 The aqueous solution was sequentially added to 49mL of ultrapure water to prepare TA / Fe Ⅲ complexes;

[0040] (3) adding graphene to ultrapure water to configure a mixed solution whose mass concentration is 0.1 mg / mL;

[0041] (4) Put the mixed solution of step (3) into an ultrasonic cell pulverizer under an ice-water bath and sonicate for 36 minutes;

[0042] (5) Add the TA / Fe prepared in step (2) to the mixed solution after ultrasonication in step (4) Ⅲ Complex compound (mass ratio: tannic acid: graphene=...

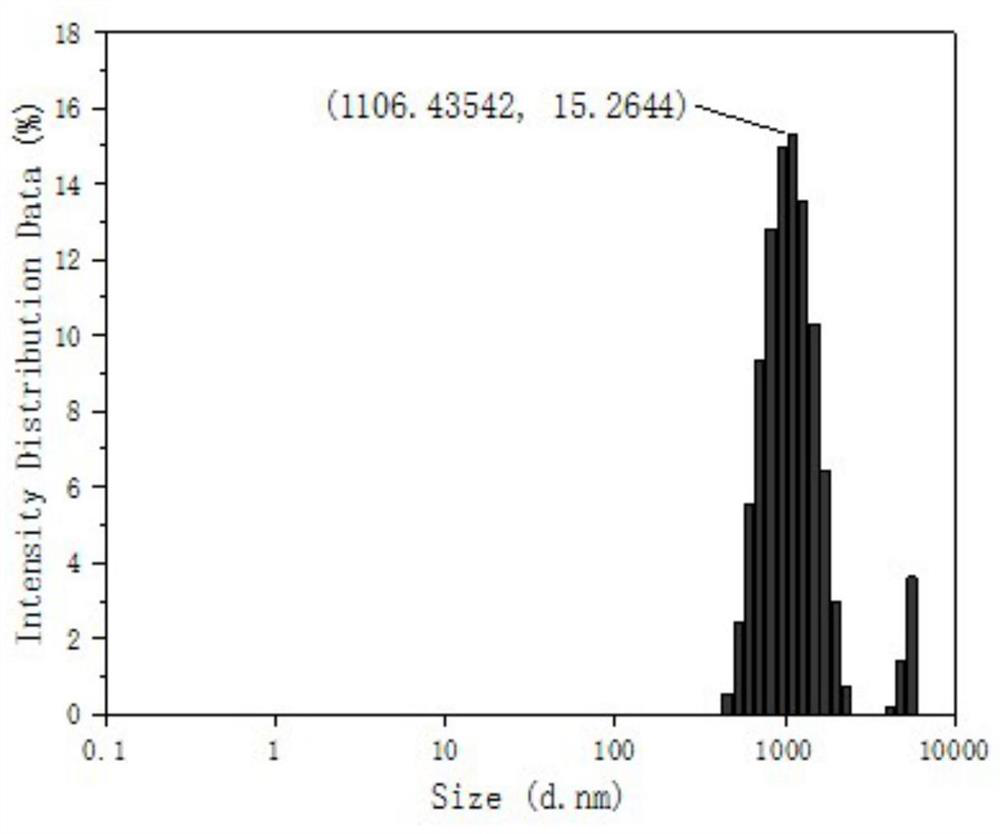

Embodiment 3

[0045] A method of utilizing tannic acid metal complexes to realize the dispersion and transfer of all kinds of nano-carbon materials, the specific steps are as follows:

[0046] (1) Tannic acid (TA) and FeCl 3 ·6H 2O is added with ultrapure water to prepare respectively the molar concentration of 24mM tannic acid (TA) aqueous solution and 37mM FeCl 3 aqueous solution;

[0047] (2) get the 0.5mL tannic acid (TA) aqueous solution and 0.5mlFeCl that step (1) obtains 3 The aqueous solution was sequentially added to 49mL of ultrapure water to prepare TA / Fe Ⅲ complexes;

[0048] (3) adding graphene to ultrapure water to configure a mixed solution whose mass concentration is 0.1 mg / mL;

[0049] (4) Put the mixed solution of step (3) into an ultrasonic cell pulverizer under an ice-water bath and sonicate for 36 minutes;

[0050] (5) Add the TA / Fe prepared in step (2) to the mixed solution after ultrasonication in step (4) Ⅲ Complex compound (mass ratio: tannic acid: graphene=1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com