Linear double-piston air compressor

An air compressor and dual-piston technology, applied in piston pumps, mechanical equipment, machines/engines, etc., can solve the problems of low air compression effect and efficiency, and achieve good air compression effect and low vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

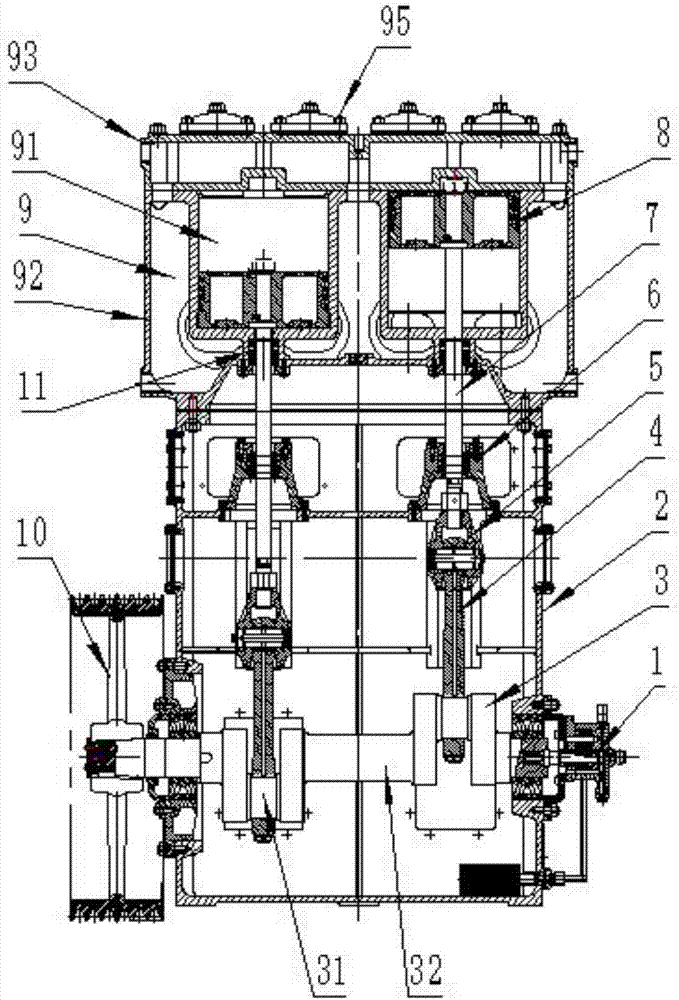

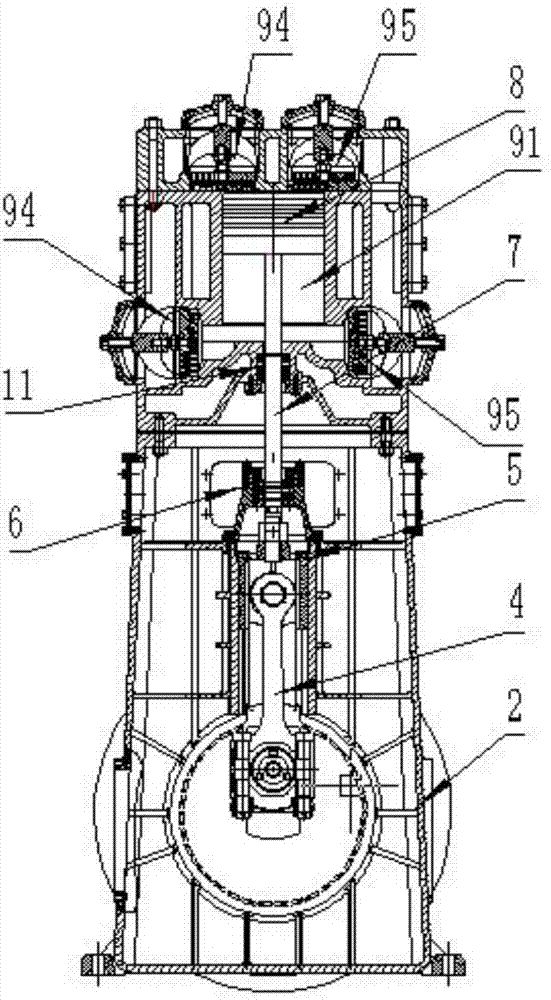

[0026] Such as Figures 1 to 5 As shown, a linear dual-piston air compressor includes a crankcase 2, a cylinder block 9 with two cylinders 91, a crankshaft 3 and two piston devices connected to the crankshaft 3;

[0027] The cylinder block 9 is located above the crankcase 2 and is fixedly connected;

[0028] The crankshaft 3 runs through the crankcase 2, and both ends are fixed in the crankcase 2 by bearings; one end is connected to the oil pump device 1, and the other end is connected to the pulley 10 connected to the motor; the two connecting rod journals 31 in the crankshaft 3 are symmetrical along the main shaft 32 direction;

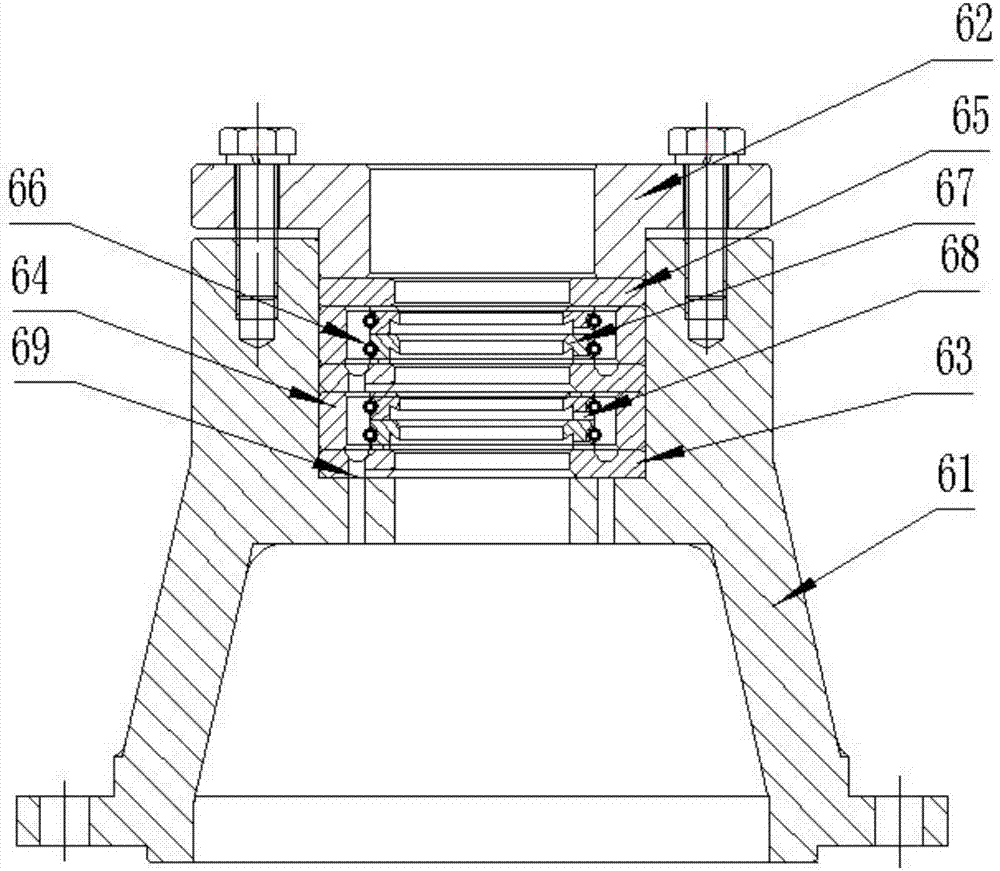

[0029] Described piston device comprises the connecting rod 4 that is connected with the connecting rod journal 31 of crankshaft 3, and connecting rod 4 is connected with piston rod 7 through cross joint 5, and piston rod 7 is connected wi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap