Real-time regression detection system and method for solid rocket propellant burning surface

A solid rocket, real-time detection technology, used in measurement devices, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc., can solve problems such as large measurement errors and uneven combustion surfaces, to reduce detection errors and improve detection. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

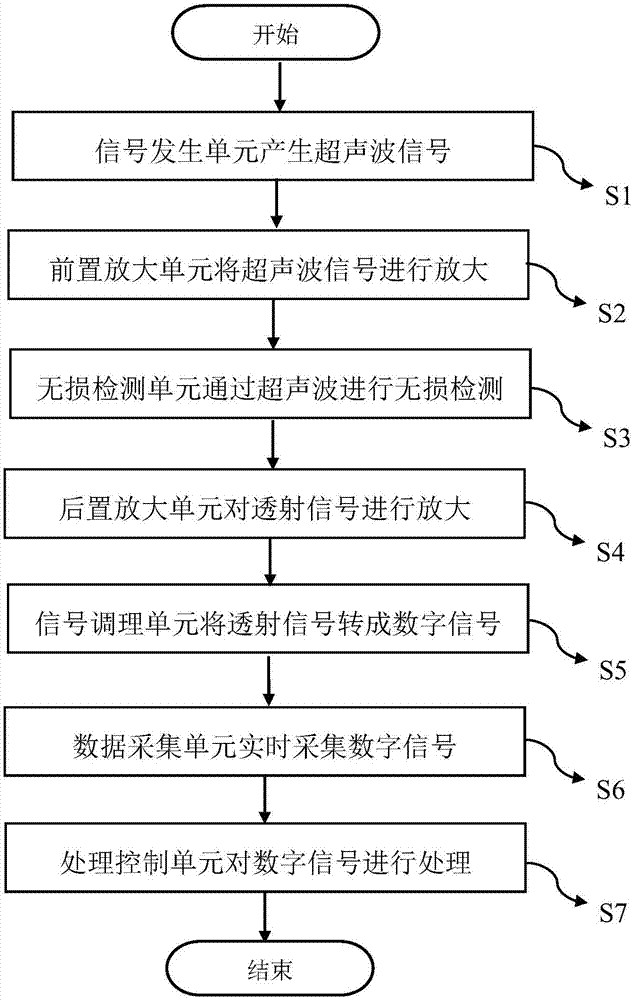

[0021] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

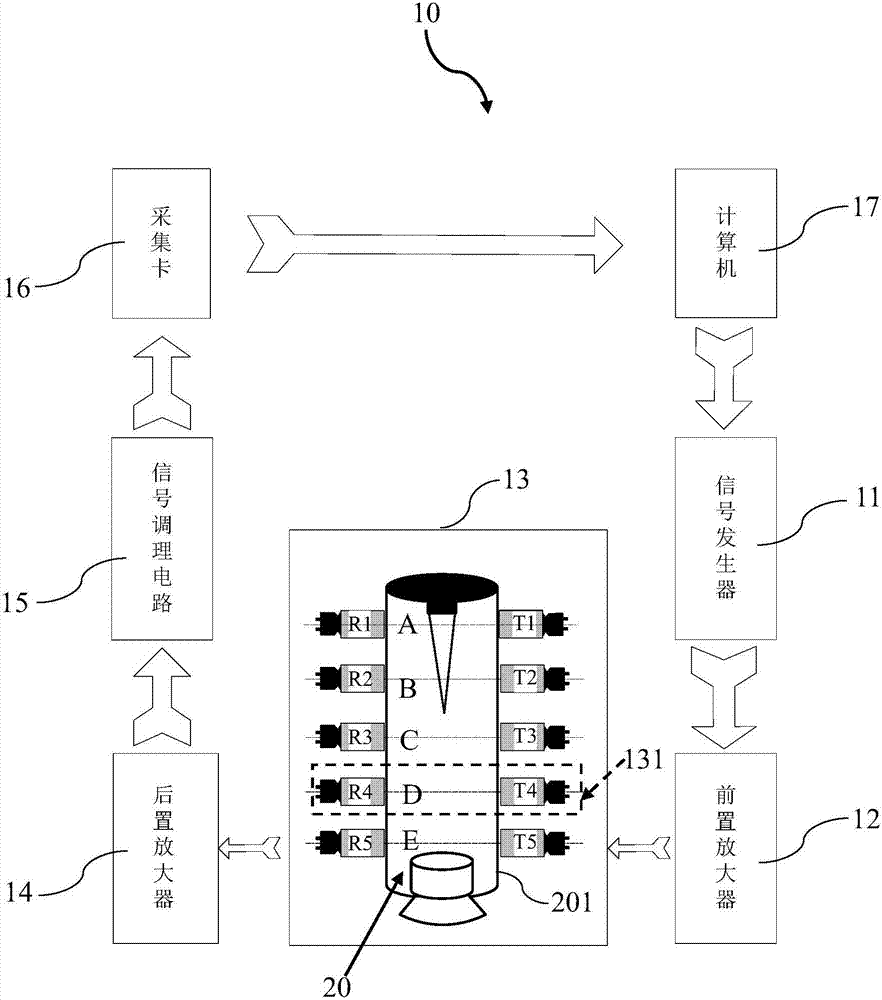

[0022] figure 1 It is a structural schematic diagram of the real-time detection system for the solid rocket propellant combustion surface retreat in this embodiment.

[0023] Such as figure 1 As shown, the solid rocket propellant combustion surface retreat real-time detection system 100 adopts the working mode of non-contact measurement of ultrasonic transducer. It includes a signal generation unit 11 , a pre-amplification unit 12 , a non-destructive testing unit 13 , a post-amplification unit 14 , a signal conditioning unit 15 , a data acquisition unit 16 and a processing control unit 17 .

[0024] The signal generating unit 11 is used for generating an ultrasonic signal as an original pulse signal; the preamplifying unit 12 is used for amplifying the ultrasonic signal.

[0025] The non-destructive testing unit 13 is arranged near the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com