Lamination screening device for detecting dispersion gluing and baking of relay

A screening device and detection point technology, applied in the direction of relays, circuits, electrical components, etc., can solve the problems of many defective products in manual pressing, low efficiency of manual loading and unloading, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

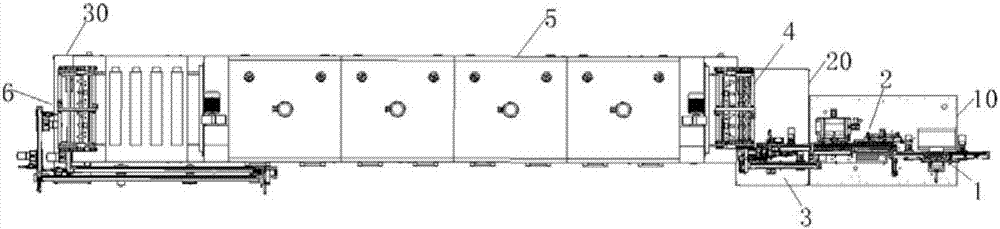

[0027] A relay detection dispensing baking device, comprising a tunnel furnace 5, a feeding mechanism installed at the feed end of the tunnel furnace 5 and a feeding mechanism 6 at the discharge end of the tunnel furnace 5, the feeding mechanism includes sequentially connected The feed magnetizing device 1, the mobile positioning dispensing mechanism 2, the pressing and screening device 3 and the feeding device 4, the feeding magnetizing device 1 and the mobile positioning dispensing mechanism 2 are installed on a workbench 10 , the pressing and screening device 3 and the feeding device 4 are installed on the workbench 2 20;

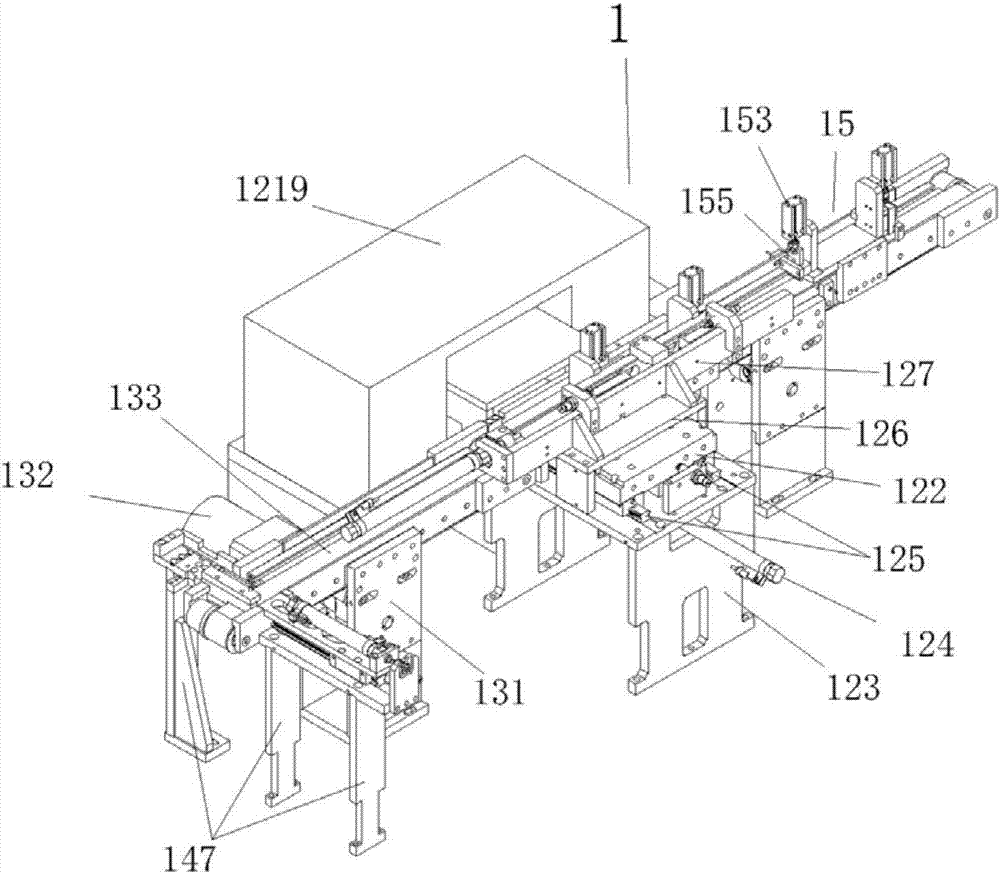

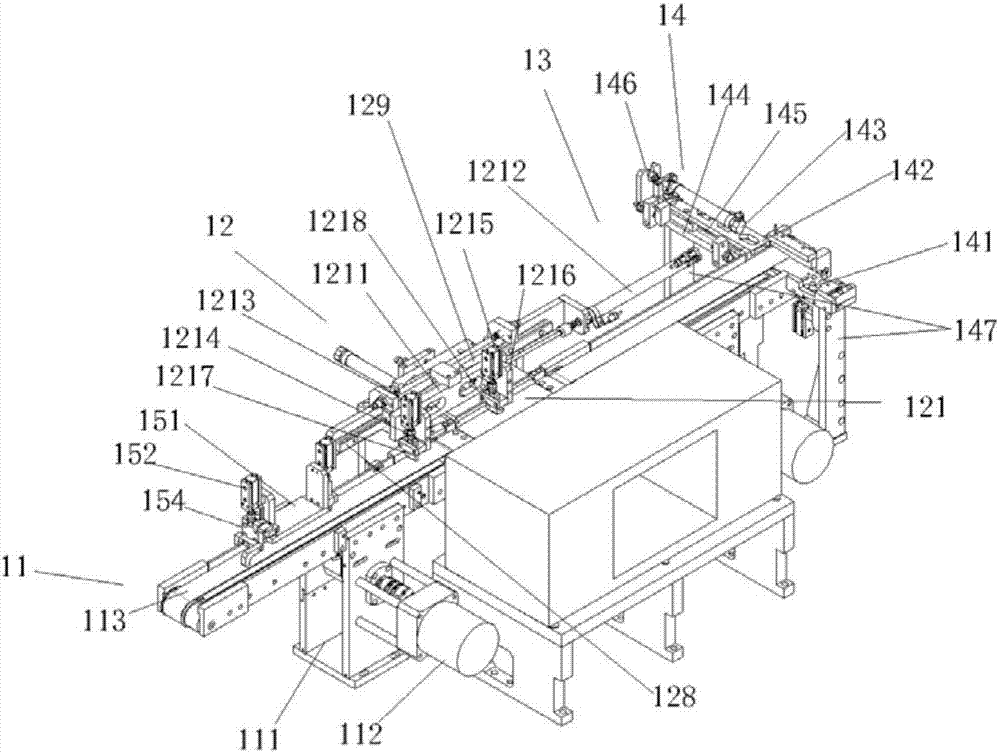

[0028] The feeding magnetizing device 1 includes a conveying device 11, a magnetizing device 12, a conveying device 13 and a pushing device 14 installed on the workbench 10 in sequence; the conveying device 11 includes a base 111 Be installed on the workbench one 10 and drive the conveyor belt one 113 by the motor one 112 installed on the base one 111, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com