A workpiece recognition and sorting device and method based on multiple image acquisition equipment

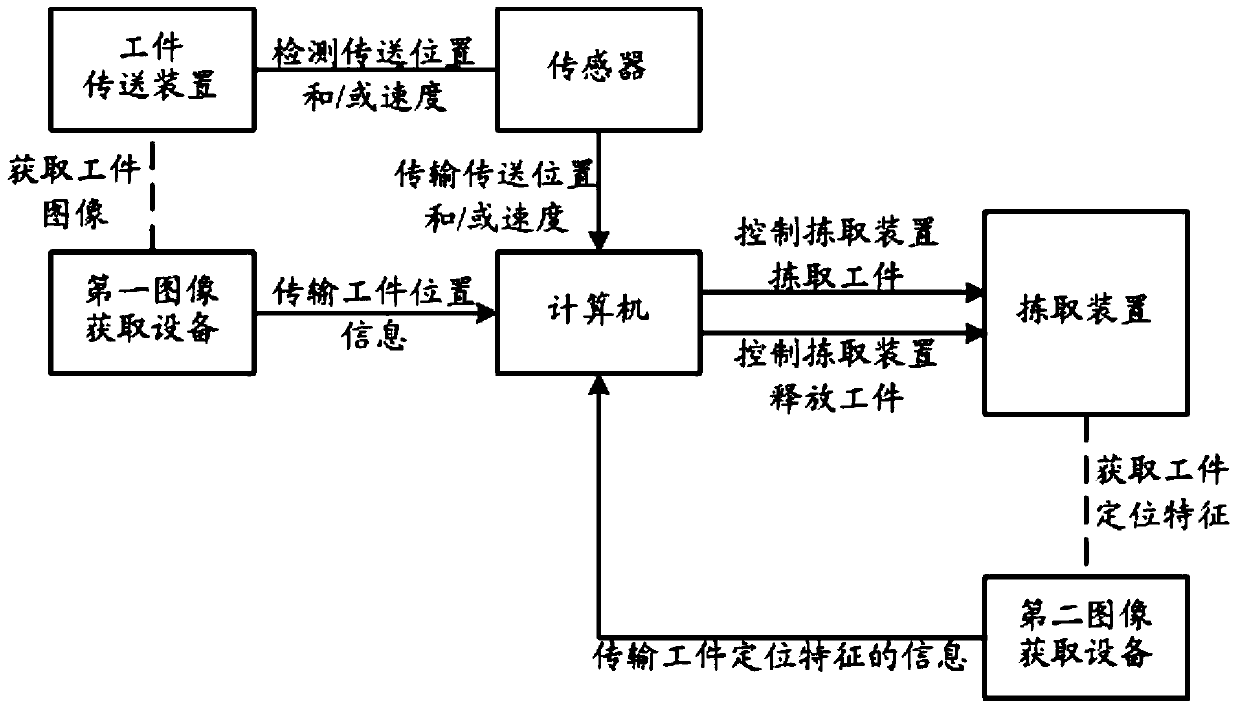

An image acquisition and sorting device technology, applied in sorting and other directions, can solve the problems of not being able to fully utilize the efficiency of cameras and the increase in the number of cameras, and achieve high-precision recognition and picking, improve utilization, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

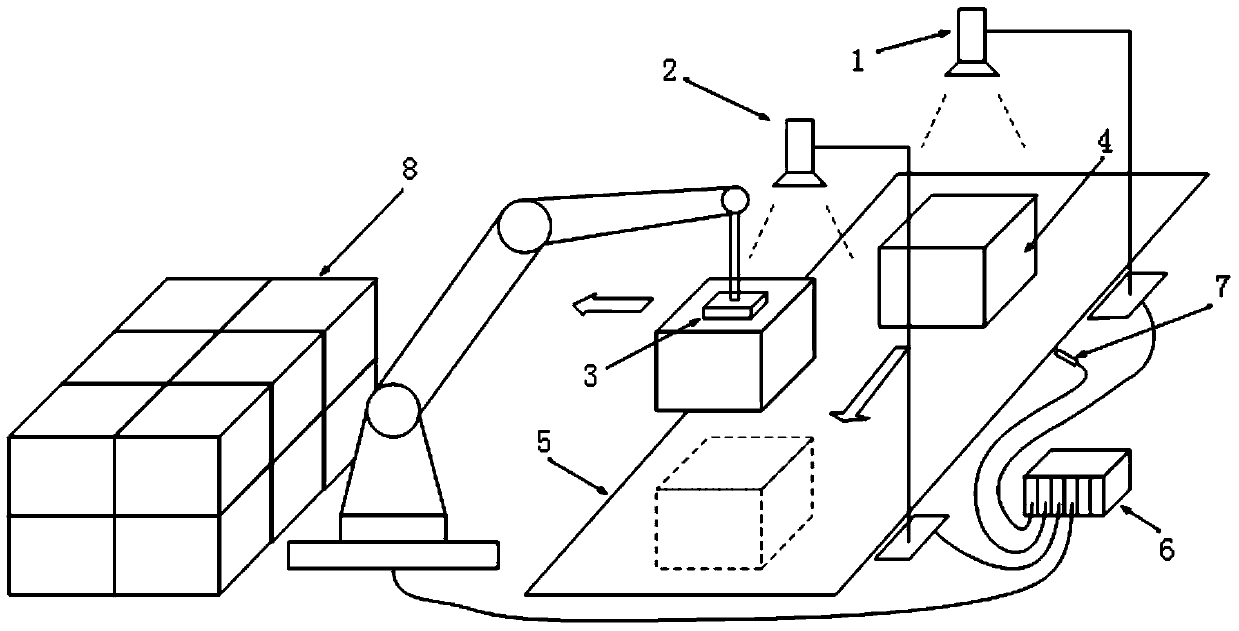

[0050] The workpiece transmission device is a conveyor belt, the pick-up device is a multi-joint robot, and the workpiece is a box. Both the first camera and the second camera are industrial cameras of common specifications with a resolution of 5 million pixels. The conveyor belt is driven by a rotating motor. A rotary encoder is installed on the motor to detect the rotation angle of the motor. The computer calculates the moving distance and speed of the conveyor belt by continuously reading the angle fed back by the encoder.

[0051] The first camera is fixedly installed directly above the workpiece entering direction of the conveyor belt, the lens points vertically downward to the sorting area, the second camera is one and is fixedly installed directly above the workpiece sorting area downstream of the conveyor belt, and the lens points vertically downward to the sorting area pick area,

[0052] A) The first camera collects images of multiple workpieces upstream of the conv...

Embodiment 2

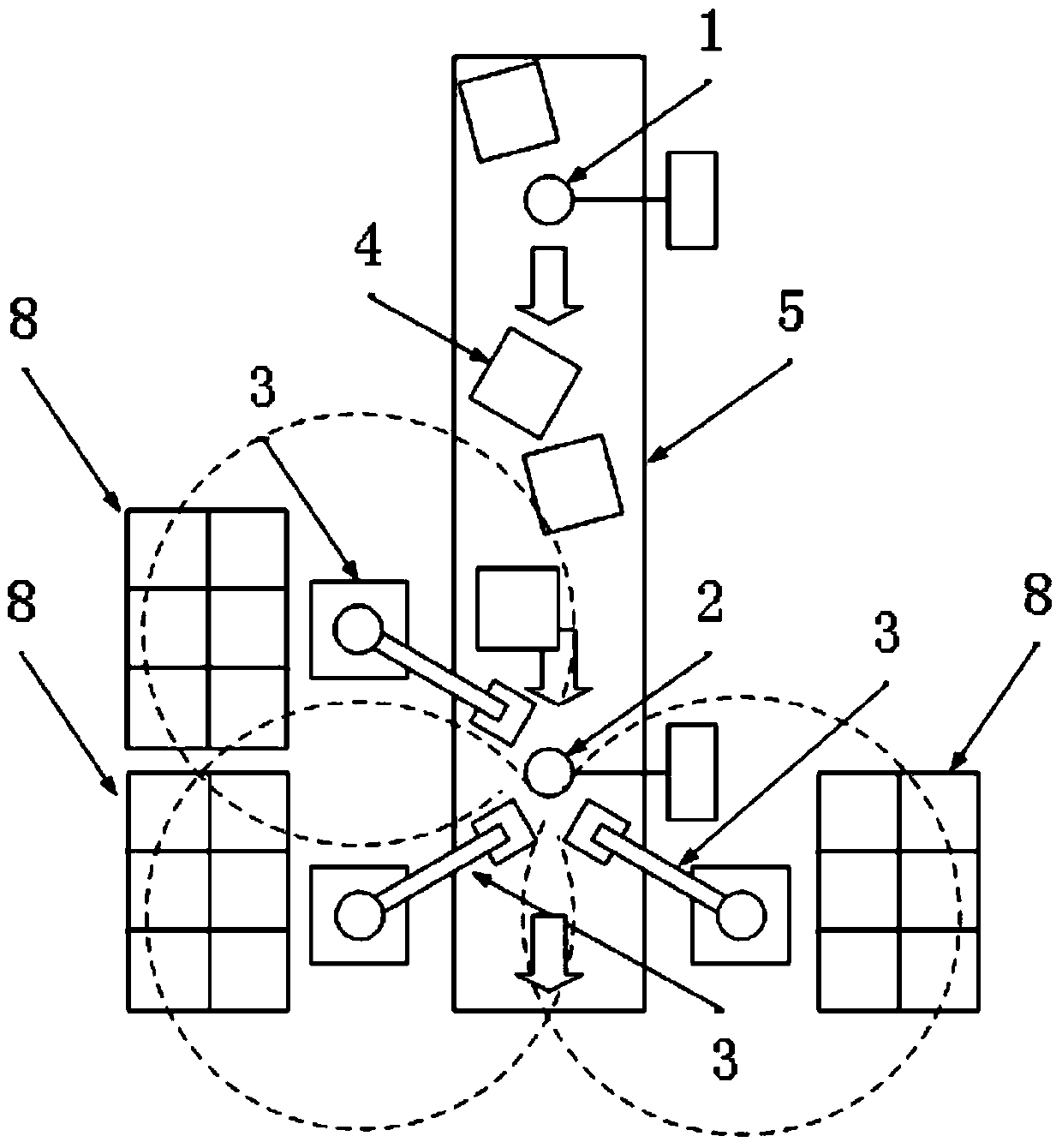

[0061] The workpiece transmission device is a conveyor belt, the pick-up device is two multi-joint robots, and there are also two second cameras corresponding to the positions of the two robots. The workpiece is a box. Both the first camera and the second camera are industrial cameras with common specifications, and their pixel arrays are 1920*2560. The conveyor belt is driven by a rotating motor with a constant speed, and the computer calculates the moving distance and speed of the conveyor belt through the motor speed setting.

[0062] The first camera is fixedly installed directly above the upstream of the workpiece entering direction of the conveyor belt, the lens points vertically downward to the sorting area, the second camera is fixedly installed directly above the workpiece sorting area downstream of the conveyor belt, and the lens points vertically downward to the sorting area,

[0063] Two multi-joint robots and two second cameras are arranged at a certain distance ...

Embodiment 3

[0073] The workpiece transmission device is a conveyor belt, the picking device is two multi-joint robots, and the second camera is one. The workpiece is a box. Both the first camera and the second camera are industrial cameras with common specifications, and their pixel arrays are 1920*2560. The conveyor belt is driven by a rotating motor. A rotary encoder is installed on the motor to detect the rotation angle of the motor. The computer calculates the moving distance and speed of the conveyor belt by continuously reading the angle fed back by the encoder.

[0074] The first camera is fixedly installed directly above the upstream of the workpiece entering direction of the conveyor belt, the lens points vertically downward to the sorting area, the second camera is fixedly installed directly above the workpiece sorting area downstream of the conveyor belt, and the lens points vertically downward to the sorting area,

[0075] Two multi-joint robots are arranged at a certain dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com