Rubber track

A rubber crawler and crawler technology, applied in the field of rubber crawlers, can solve the problems of being unable to suppress crack growth, unable to suppress growth, etc., and achieve the effect of suppressing the generation of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, one embodiment of the present invention will be described based on the drawings.

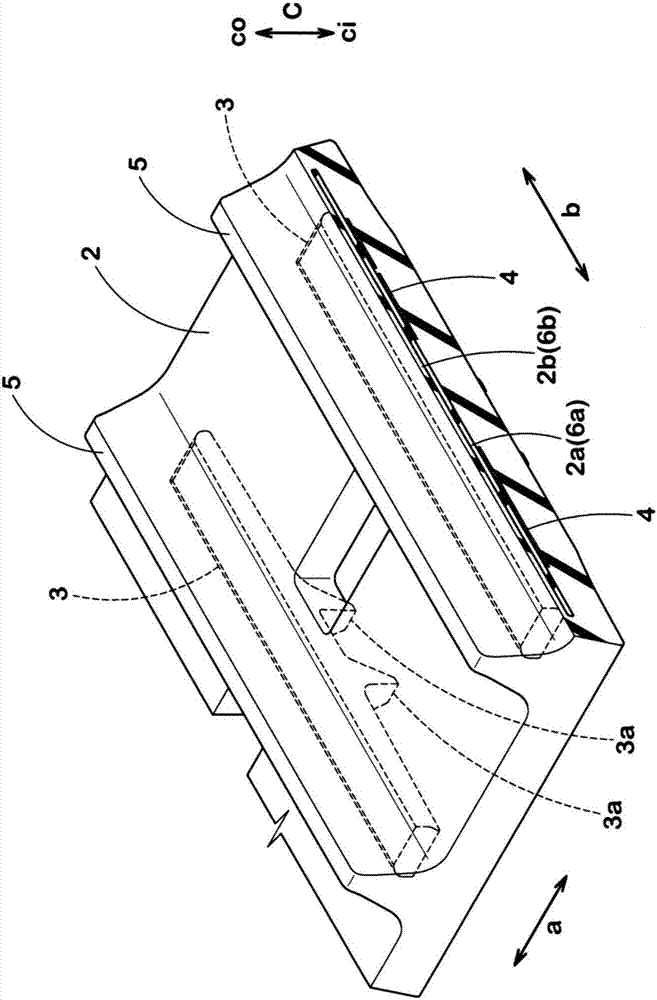

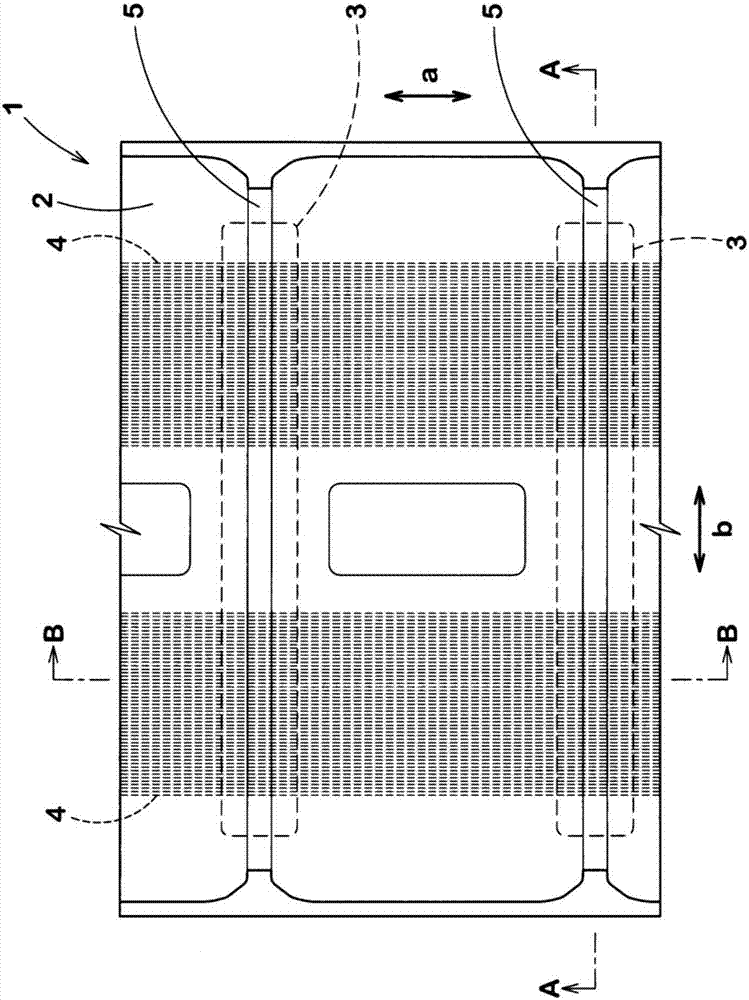

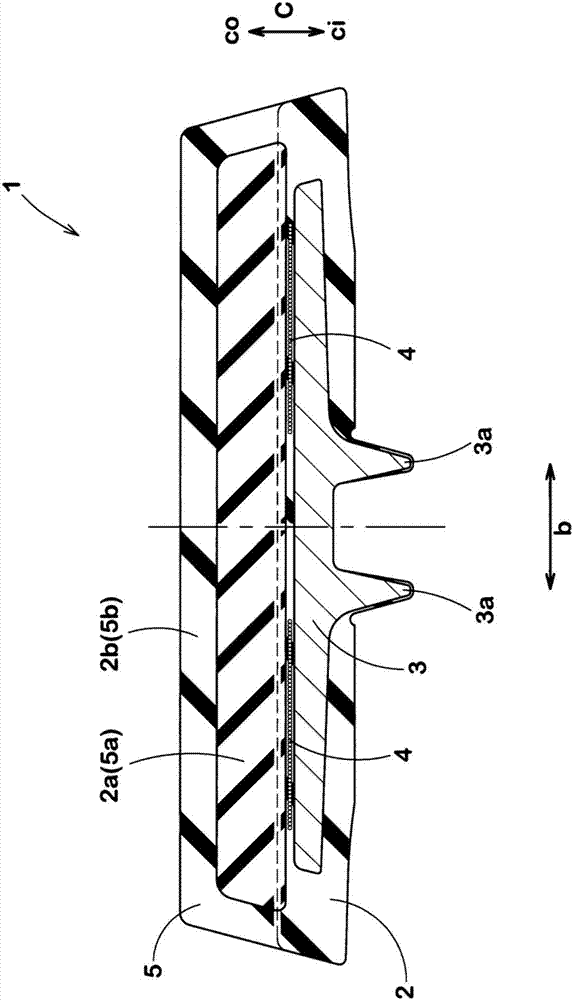

[0026] figure 1 It is a perspective view which shows the rubber crawler 1 of this embodiment. Such as figure 1 As shown, the rubber crawler 1 of the present embodiment includes a crawler main body 2 formed of rubber in an endless belt shape, a plurality of mandrels 3 embedded in the crawler main body 2 , and a tensile body 4 .

[0027] In this specification, the track circumferential direction is the rotation direction of the rubber track 1, which is equivalent to figure 1 The reference sign a indicates the direction. In addition, the track width direction is the axial direction of the driving wheel, floating wheel and roller when the rubber track 1 is installed on the vehicle, which is equivalent to figure 1 The direction indicated by the reference sign b. In addition, the track thickness direction is a direction perpendicular to the track circumferential direction and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap