Cleaning oil filtering and recycling system used for sheet cleaning machine

A recovery system and cleaning machine technology, applied in the field of cleaning machines, can solve the problems of affecting the service life of filters, easy to block filters, waste, etc., and achieve the effect of good recovery and purification effect, good purification effect and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

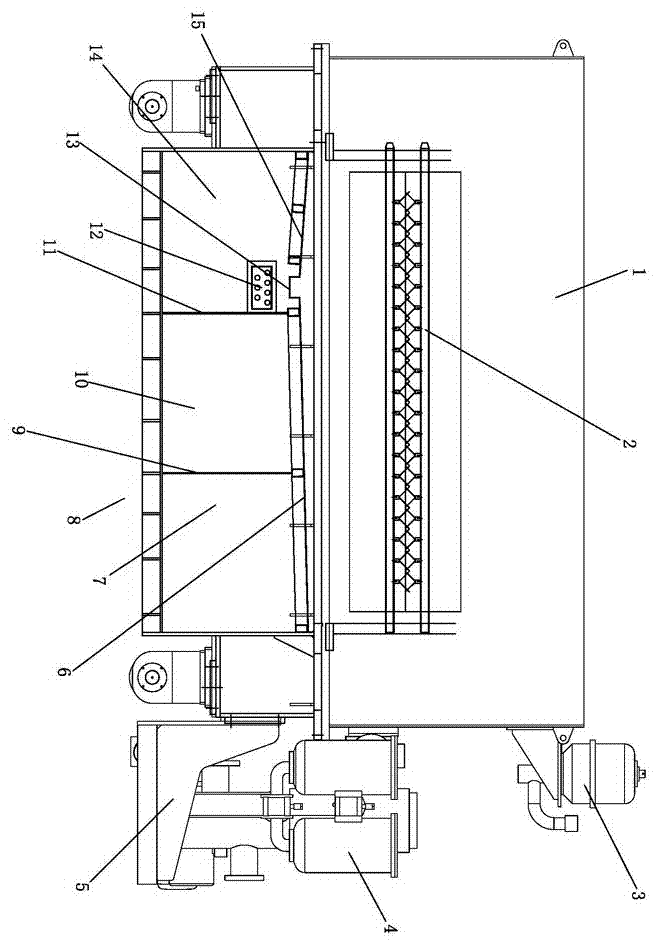

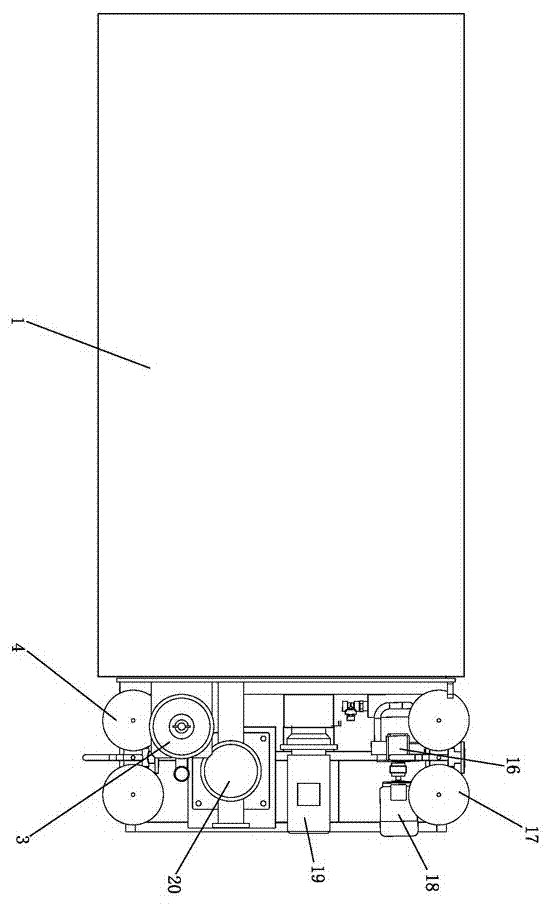

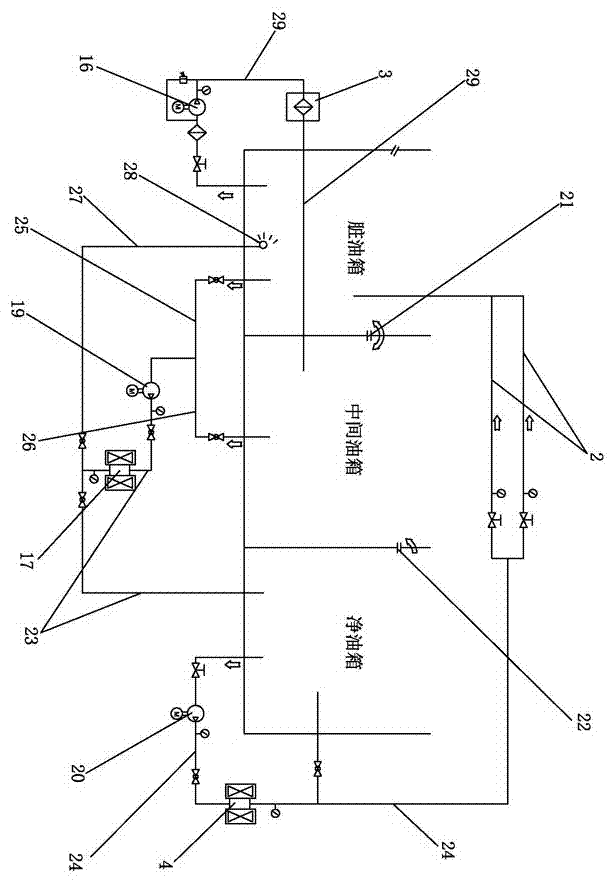

[0020] Such as Figure 1-3 As shown, a cleaning oil filtration and recovery system for a sheet metal cleaning machine includes an upper frame 1, and also includes a flushing nozzle 2 arranged on the upper frame 1 for flushing the sheet metal, and also includes an upper frame 1 The cleaning machine oil tank 8 below the frame 1 also includes the installation seat 5 arranged on one side of the cleaning machine oil tank 8, and also includes a primary filter system, a secondary filter system, a tertiary filter system, and a four-stage filter system for recycling dirty oil ; The cleaning machine oil tank 8 is provided with a first dividing plate 11 and a second dividing plate 9, and the cleaning machine oil tank 8 includes a dirty oil tank 14, an intermediate oil tank 10, and a clean oil tank 7; the dirty oil tank 14 and the intermediate oil tank 10 pass through the first dividing plate 11 separated, the middle fuel tank 10 and the net fuel tank 7 are separated by the second partiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com