Aluminum-steel dissimilar metal riveting and welding composite connection method

A technology for dissimilar metals and composite connections, applied in welding equipment, metal processing equipment, welding/welding/cutting items, etc., and can solve problems such as cracking and poor fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

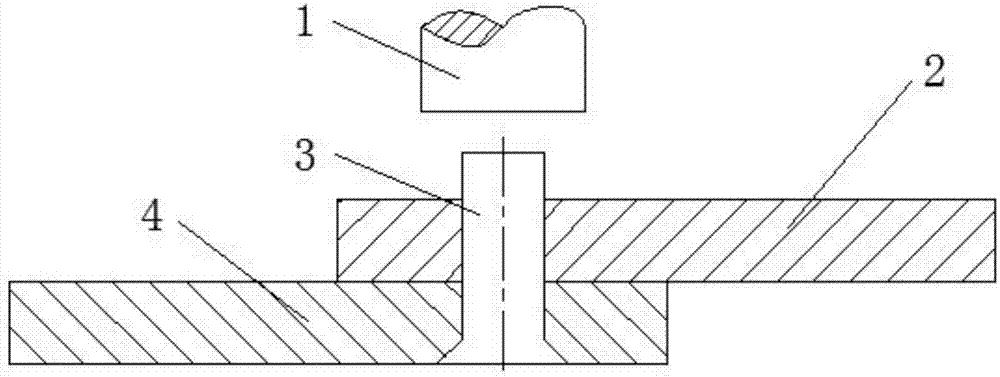

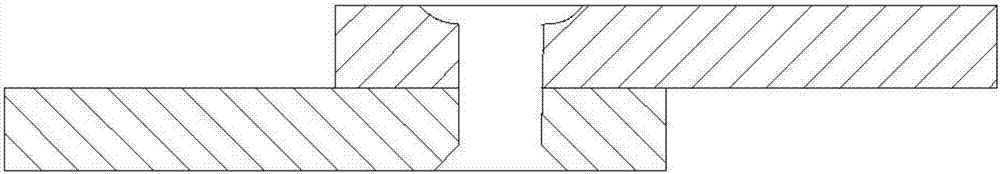

[0042] First, cut the 4mm thick 2A14 aluminum alloy into 100mm×40mm×4mm plates, and also cut the 2mm thick galvanized steel plate into 100mm×40mm×2mm samples to be welded, and use a drill with a diameter of 4mm at the riveting point. Drilling, drill a tapered countersunk hole in the lower part of the steel plate, polish the butt joint surface with 400# sandpaper, and clean the drilling burr with a file, and finally clean the joint with acetone;

[0043] Insert the cleaned rivet with a tapered rivet head from below. The material of the rivet is 2A14 aluminum alloy. The bottom of the rivet is flush with the bottom of the lower plate, and the upper part is 4mm higher than the upper plate. Clamp and wait for welding;

[0044] A 12mm-diameter end surface without a stirring pin is used to rotate and press in the stirring head, and the rotation speed of the stirring head is 1500r / min. When the end surface of the stirring head contacts the upper plate, press down 0.2mm and keep for 30s...

Embodiment 2

[0047] First, cut the 4mm thick 2A14 aluminum alloy into 100mm×40mm×4mm plates, and also cut the 2mm thick galvanized steel plate into 100mm×40mm×2mm samples to be welded, and use a drill with a diameter of 6mm at the riveting point. Drilling, drill a tapered countersunk hole in the lower part of the steel plate, polish the butt joint surface with 400# sandpaper, and clean the drilling burr with a file, and finally clean the joint with acetone;

[0048] Insert the cleaned rivet with a tapered rivet head from below. The material of the rivet is 7A04 aluminum alloy. The bottom of the rivet is flush with the bottom of the lower plate, and the upper part is 4mm higher than the upper plate. Clamp and wait for welding;

[0049] A stirring head with a diameter of 16mm and no stirring needle is used to rotate and press in. The rotating speed of the stirring head is 1500r / min. When the end face of the stirring head is in contact with the upper plate, press down 0.2mm, and the welding ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com