A Lightweight Skin Skeleton Wing Integral Diffusion Connection Forming Method

A diffusion connection, lightweight technology, applied in welding equipment, non-electric welding equipment, manufacturing tools, etc., can solve the problems of the width limitation of the skeleton ribs, affecting the weight of the wing parts, and the low product qualification rate, and achieve the increase of the wing. The effect of bearing capacity, improving product qualification rate and production efficiency, and reducing the weight of the wing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

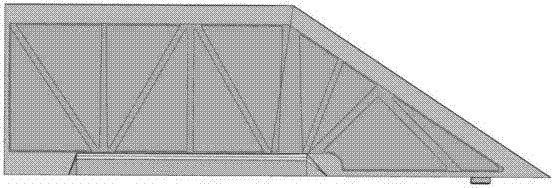

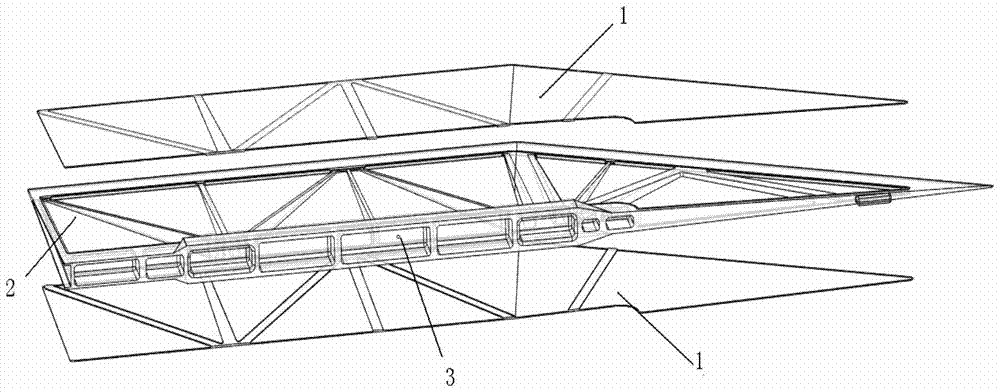

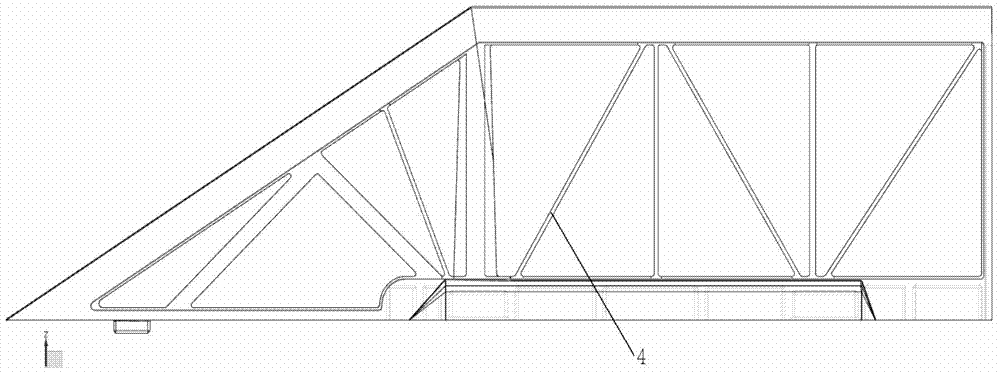

[0025] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The overall diffusion connection method of lightweight skin skeleton wing parts provided by the present invention comprises the following steps:

[0026] (1) Cutting the skin parts, bending and forming parts that meet the requirements of the profile.

[0027] (2) After casting, the frame is machined according to the design model, and the frame is designed with air holes at the wing root.

[0028] (3) Polish the parts where the skeleton and the skin need to be diffused and connected, and the surface roughness is required to be at least 3.2.

[0029] (4) Electron beam welding is performed on the periphery of the skin and the sunken part of the skeleton to form a closed cavity inside, and air pressure can be applied to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com