welding bracket

A technology for welding brackets and welding surfaces, which is applied to the connection between superstructure subassemblies, superstructure subassemblies, vehicle parts, etc., and can solve the problems of difficult production of special-shaped beams, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

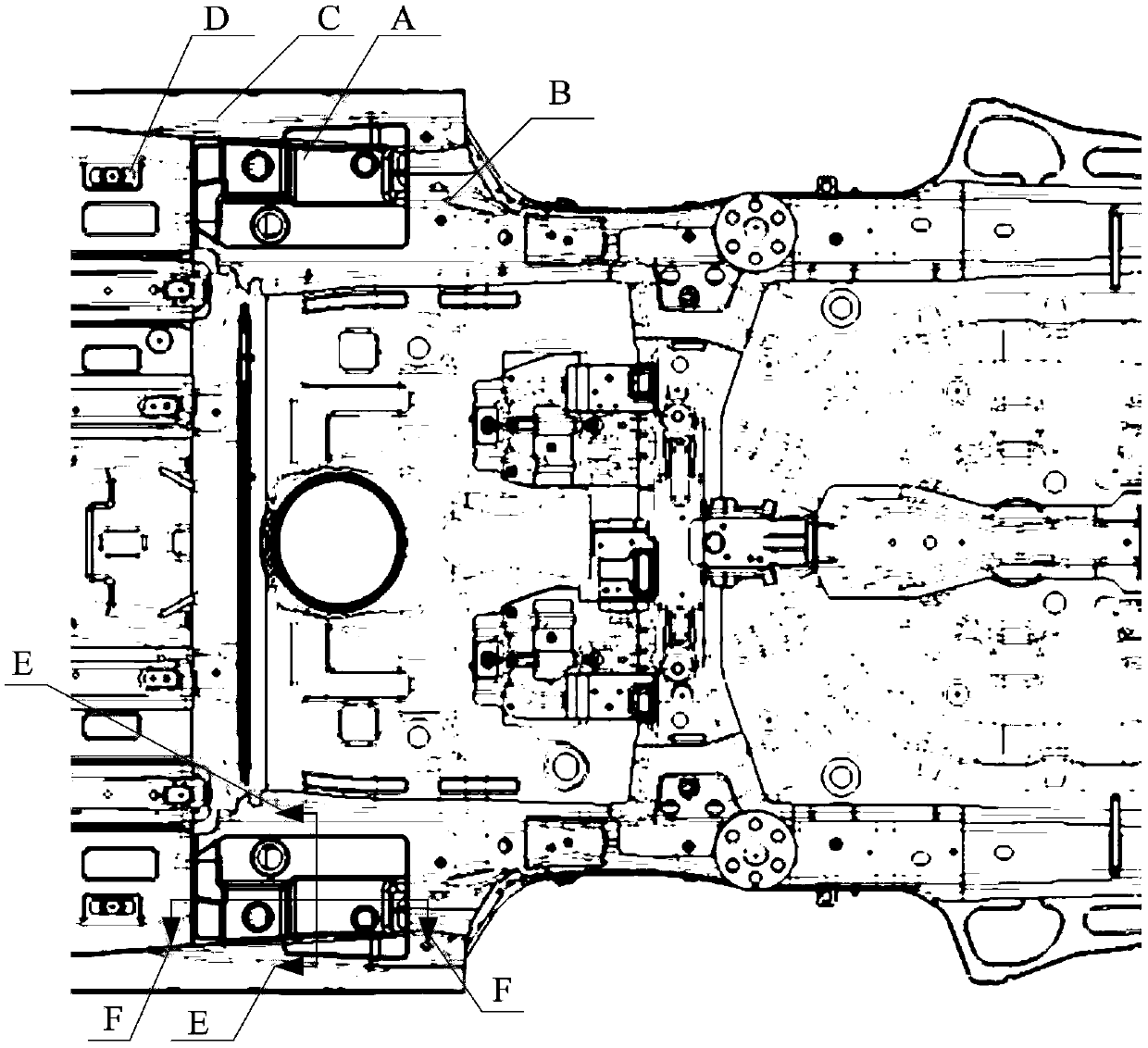

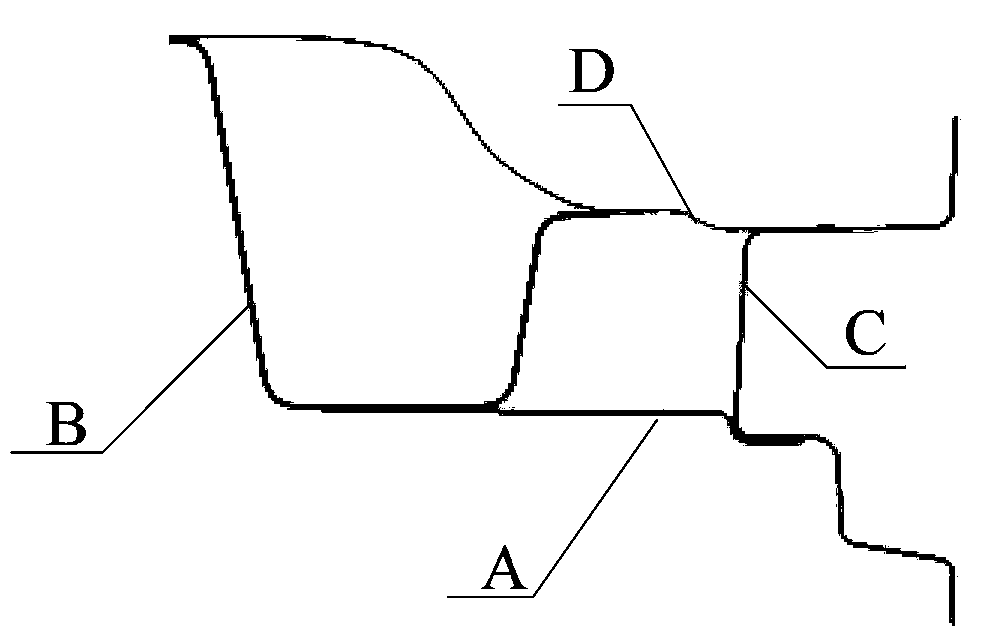

[0045] figure 1 The usage scene diagram of Embodiment 1 of the welding bracket provided by the present invention. refer to figure 1 , for vehicles with gaps between the rear longitudinal beam assembly structure B of the car body, the rear section assembly structure C of the door sill inner panel, and the front extension panel assembly structure D of the rear floor, the two provided by the present invention The welding bracket A is symmetrically arranged on the gap between the above three assembly structures to fill the gap between the above three assembly structures.

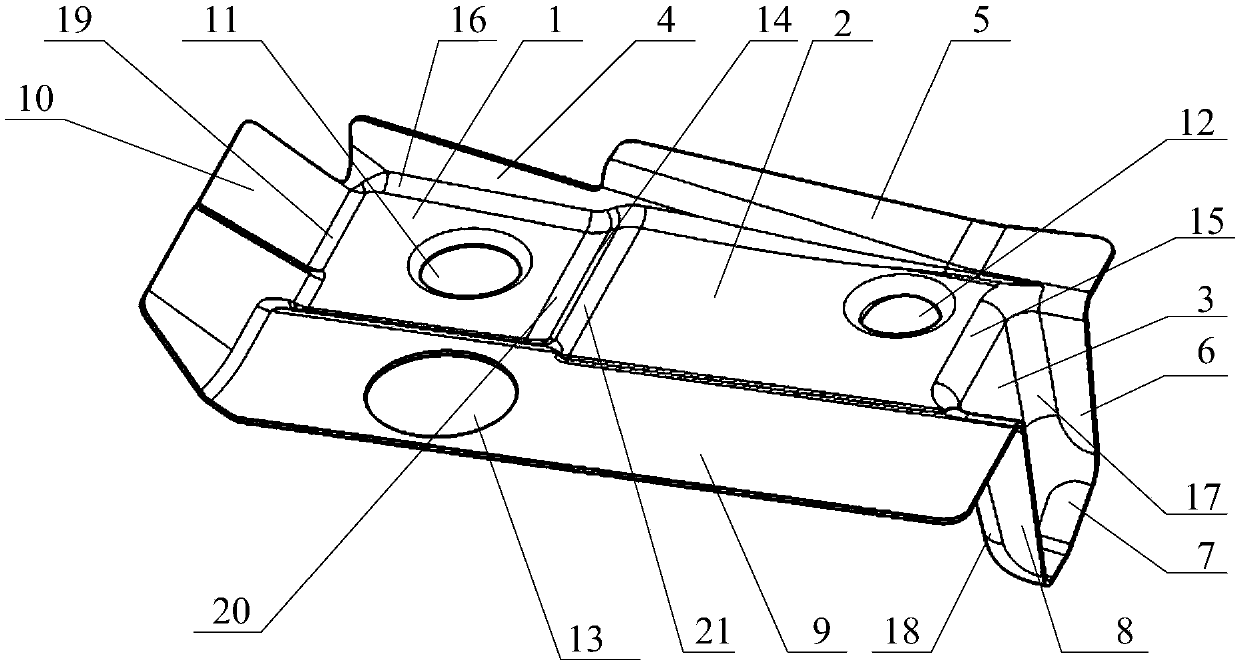

[0046] figure 2 For the structural schematic diagram of Embodiment 1 of the welding bracket provided by the present invention, refer to figure 2 . The welding space A provided by the present invention includes: three rectangular base surfaces and seven welding surfaces.

[0047] Among them, the connection relationship between the welding surface and the base surface is as follows:

[0048] The first recta...

Embodiment 2

[0059] This embodiment is carried out on the basis of Embodiment 1. refer to figure 2 , the welding bracket provided in this embodiment further includes: a first burring hole 11 , a second burring hole 12 and a third via hole 13 .

[0060] Wherein, the first flanging hole 11 is arranged on the first rectangular base surface 1, and the first flanging hole 11 is used as a rear positioning hole of the embrace on the assembly line.

[0061] The second flange hole 12 is arranged on the second rectangular base surface 2, the second flange hole 12 is used as the rear positioning hole of the skid on the painting production line, and the second flange hole 12 is also used as the rear suspension on the assembly line Positioning holes for module installation tooling.

[0062] The third via hole 13 is arranged on the sixth welding surface 9, and the third via hole 13 is used as a positioning hole for the rear floor assembly structure of the upper and lower vehicle bodies of the welding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com