Intelligent control device for granary grain belt conveying

An intelligent control and belt conveying technology, which is applied in the direction of conveyor control devices, transportation and packaging, conveyor objects, etc., can solve problems affecting normal production, high maintenance costs, equipment damage, etc., to achieve convenient loading and unloading operations, reduce The effect of maintenance cost and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

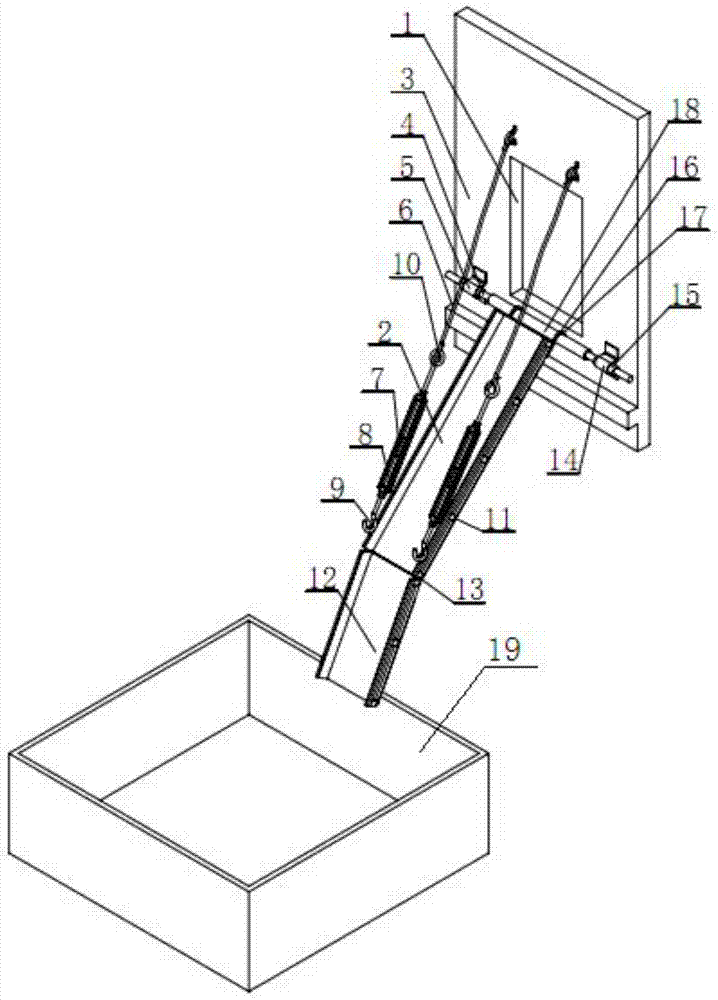

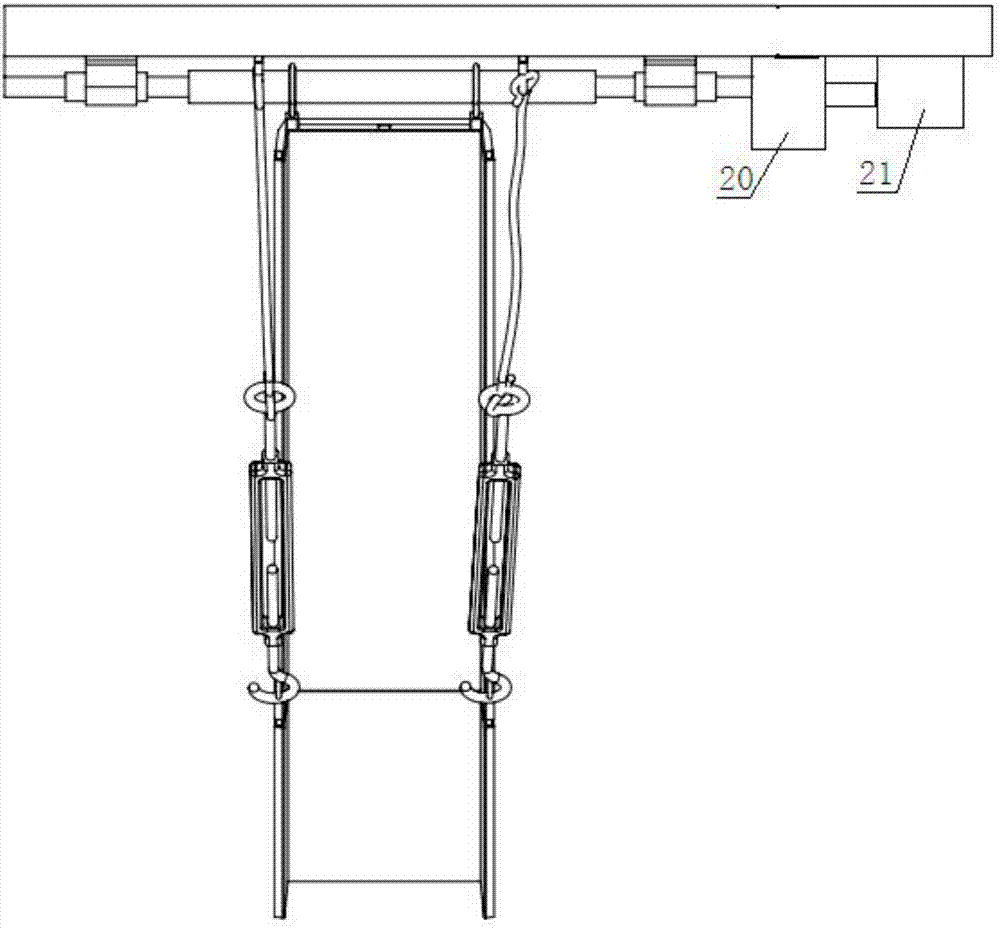

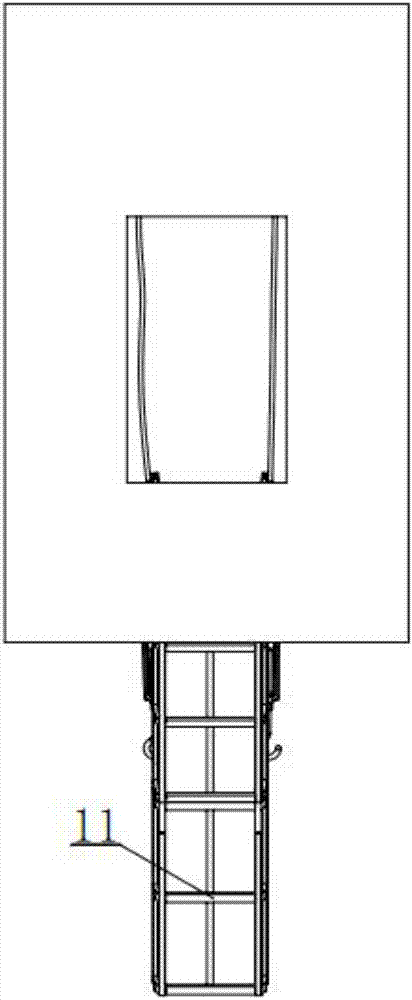

[0022] Embodiment 1: as Figure 1~Figure 5 As shown, a granary grain belt conveying intelligent control device includes a delivery port 1, the delivery port 1 is arranged on one side of the wall 3, and a chute 2 is installed on the outside of the delivery port 1, and the chute 2 is strip-shaped Groove structure, the upper end is rotatably connected to the fixed shaft seat 5 around the rotating shaft 4, the lower end is obliquely overlapped on the truck container 19, and the fixed shaft seat 5 is fixedly connected to the lower end of the outer side of the delivery port 1. One end of the rotating shaft 4 passes through After passing through the shaft seat 5, the drive motor 21 is connected through the transmission 20, which also includes a storage touch switch and a lower touch switch. The storage touch switch is installed next to the delivery port, and the lower touch switch is installed under the rotating shaft 4. After touching the receiving touch switch, the chute is put dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com