Numerical control cotton yarn impurity removing machine

A cotton yarn and miscellaneous machine technology, applied in textiles and papermaking, fiber processing, fiber opening and cleaning, etc., can solve problems such as easy thread breakage, affecting yarn quality, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

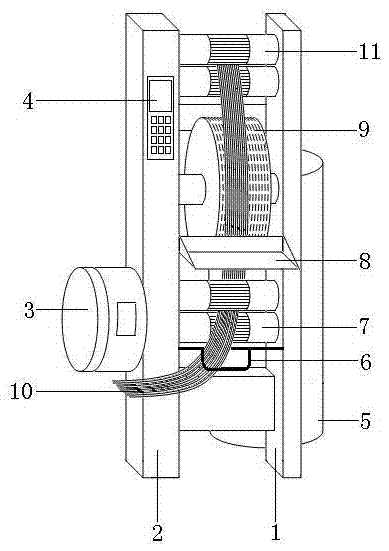

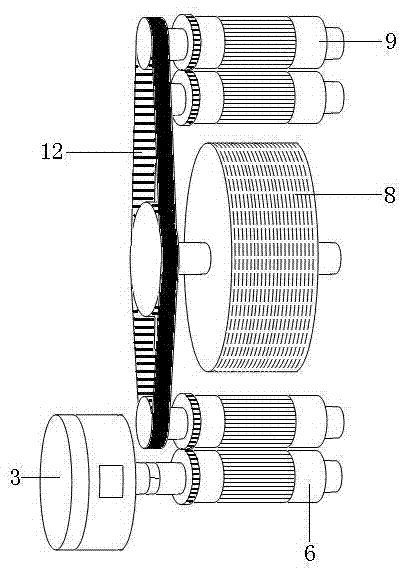

[0013] now attached figure 1 -2 further illustrate how the present invention is implemented:

[0014] CNC cotton yarn removal machine: including frame, transmission box, servo motor, digital controller, cotton yarn turnover barrel, ring sensor, lower counter-rotating drum, chute, carding wheel for removing impurities, yarn, upper counter-rotating drum, synchronous belt , the frame is connected with the transmission box through the beam, the ring sensor, the lower counter-rotating drum, the chute, the impurity removal carding wheel, the upper counter-rotating drum, the transmission box is connected with the servo motor and the digital controller, and the yarn passes through the ring sensor, The lower counter-rotating drum, trash removal carding wheel, and upper counter-rotating drum enter the cotton yarn turnover drum, and the cotton yarn turnover drum is placed behind the frame. The servo motor is connected to the lower counter-rotating drum through the main shaft, and the tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com