Special textile fabric cleaning machine

A technology for textile fabrics and cleaning machines, which is applied to textile processing machine accessories, textile material processing, and equipment configuration for processing textile materials. effect, prevent stretching and deformation, and avoid the effect of unclean cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

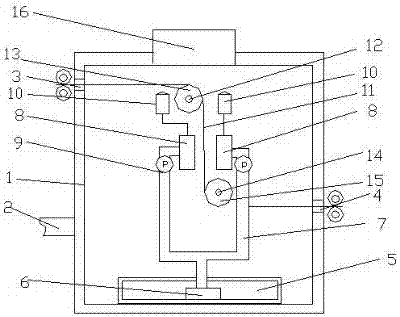

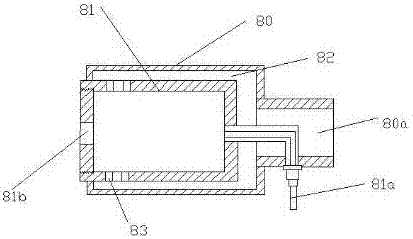

[0017] Such as figure 1 Shown, as the first embodiment of the present invention, a kind of special textile fabric cleaning machine comprises box body 1, and the side wall of described box body 1 is provided with drainage pipe 2, and on the two side walls of described box body 1 A feed port 3 and a discharge port 4 are respectively provided, and a cleaning liquid tank 5 is provided on the inner lower surface of the box body 1. A water pump 6 is provided in the cleaning liquid tank, and the water pump 6 is socketed with the upper liquid pipe 7. The upper liquid pipe 7 is a U-shaped structure, and textile fabrics are worn between the U-shaped structures of the upper liquid pipe 7, and the U-shaped structures of the upper liquid pipe 7 are respectively provided with air bubble generating devices 8, and the air bubbles generate The device 8 includes a barrel-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com