Large-span steel-timber-cable hybrid-structure system

A hybrid structure and long-span technology, applied in building structure, construction, etc., can solve the problems of large cross-section and poor bending resistance of wooden components, so as to improve the redistribution ability of internal force, ensure the bending resistance and meet the force requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

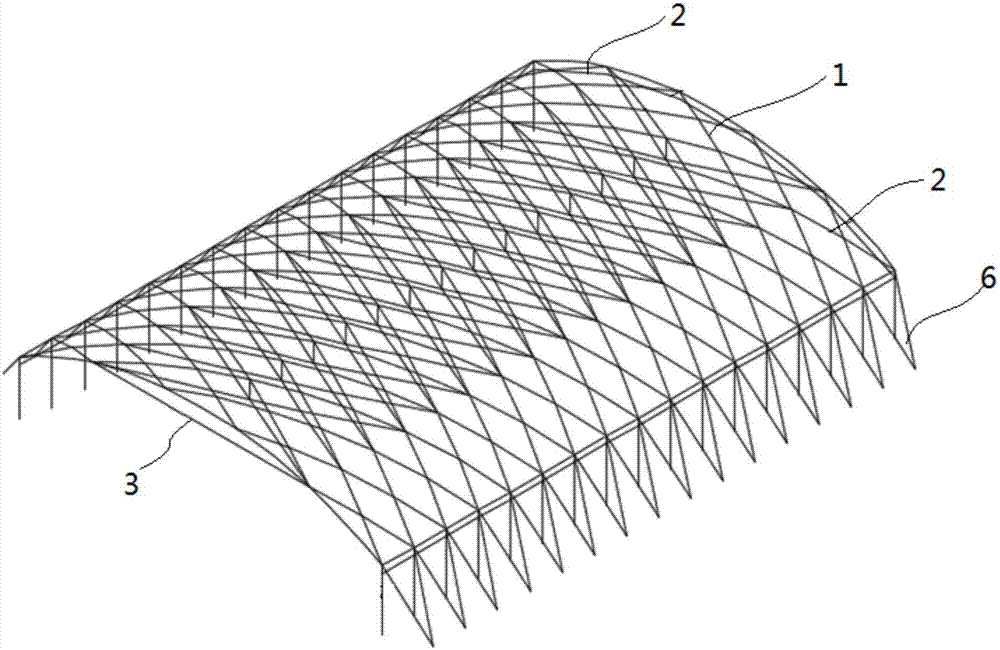

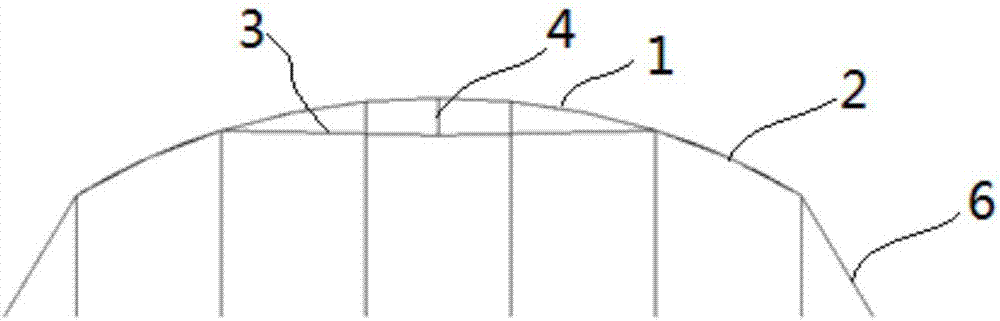

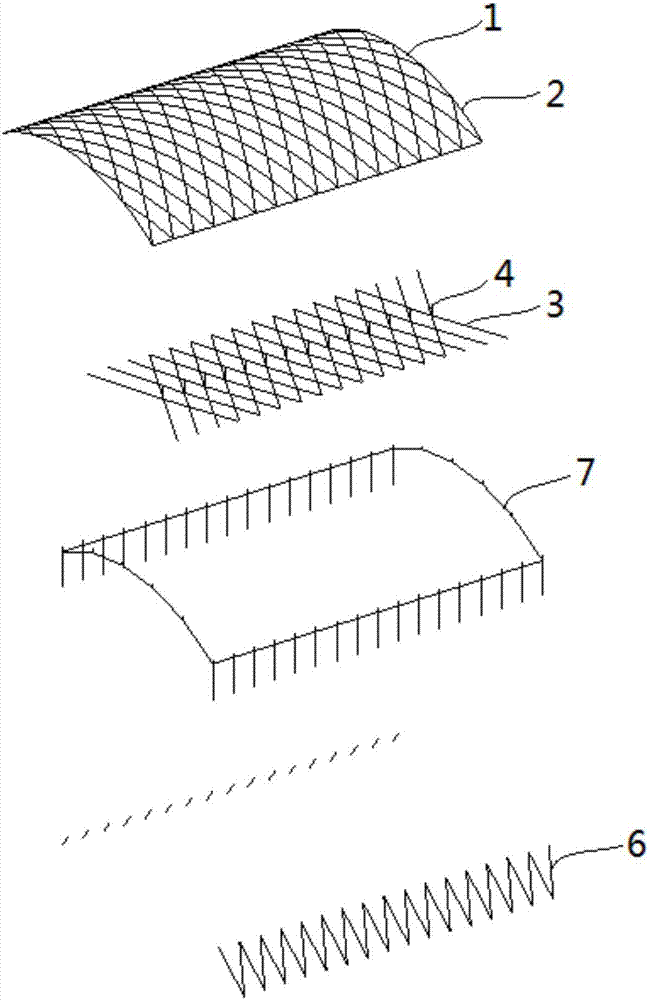

[0033] Such as Figure 1-7 As shown, a long-span steel-wood-cable hybrid structure system, the top of the system is a cross-diamond single-layer shell structure, and the middle area along the extension direction of the shell structure is mainly under pressure. According to the analysis of the internal force of the structure, the adopted structure It is a wooden reticulated shell, and both sides of the wooden reticulated shell 1 are connected to the steel reticulated shell 2, and the bending moment of the wooden reticulated shell 1 is smaller than that of the steel reticulated shell 2.

[0034] Since the current wood components are connected by metal connectors, it cannot meet the requirement of rigid connection for single-layer reticulated shells stipulated in the "Technical Regulations for Spatial Grids". The cable net support structure 3 is connected to the wooden reticulated shell 1 through the struts 4. By applying prestress to the cables, the vertical stiffness of the woo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com