Assembly-type steel structure out-hanging wall plate joint convenient to install and mold and construction technology thereof

A technology for externally hanging wall panels and external wall panels, which is applied to walls, building components, building structures, etc. It can solve the problems of poor forming effect, short construction period, and difficult operation, so as to improve stability, support performance, and connection. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

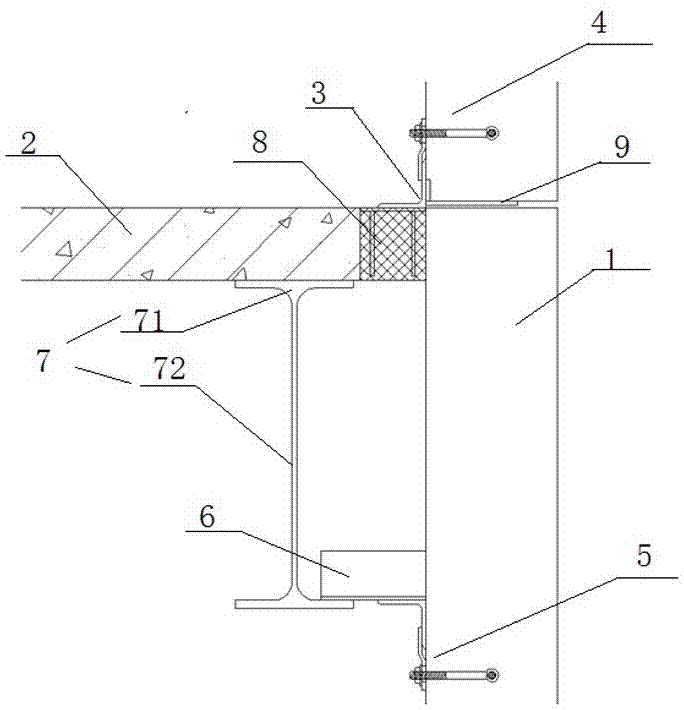

[0040] Such as figure 1 An assembled steel structure external wall panel node that is easy to install and form is shown, including: an external wall panel 1 and an external wall panel 2, wherein the external wall panel 1 is divided into an upper layer of external wall panels 11 and a lower layer of external wall panels 12 , a supporting plate 6 is provided between the upper exterior wall panel 11 and the lower exterior wall panel 12, a prefabricated embedded part 21 is provided at one end of the exterior wall panel 2, and the exterior wall panel 2 and the upper exterior wall panel 11 They are connected by the first angle steel assembly 31, a support frame 7 is provided under the external wall panel 2, and the support frame 7 and the lower exterior wall panel 12 are connected by a connecting plate 8, and the connecting plate 8 The lower side and the lower exterior wall panel 12 are fixedly connected by the second angle steel assembly 32 .

[0041] In this embodiment, the first...

Embodiment 2

[0049] As shown in the figure, an assembled steel structure external wall panel node that is easy to install and form includes: an external wall panel 1 and an external wall panel 2, wherein the external wall panel 1 is divided into an upper external wall panel 11 and a lower external wall board 12, a supporting plate 6 is provided between the upper exterior wall panel 11 and the lower exterior wall panel 12, and a prefabricated embedded part 21 is provided at one end of the exterior wall panel 2, and the exterior wall panel 2 and the upper exterior wall The plates 11 are connected by the first angle steel assembly 31, the support frame 7 is provided under the external wall panel 2, the support frame 7 and the lower outer wall panel 12 are connected by the connecting plate 8, and the connection The bottom of the board 8 is fixedly connected with the lower outer wall board 12 through the second angle steel assembly 32 .

[0050] In this embodiment, the first angle steel assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com