Self-braking support moving trolley

A self-braking and frame-moving technology, which is applied in the field of mining frame-moving vehicles, can solve problems such as inaccurate parking positions, reduced moving efficiency, and reduced production efficiency, and achieve accurate parking positions, high automation, and improved production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with accompanying drawing and specific embodiment, and present embodiment is based on the premise of technical scheme of the present invention, has provided detailed implementation and specific operation process, but protection scope of the present invention is not limited to following implementation example.

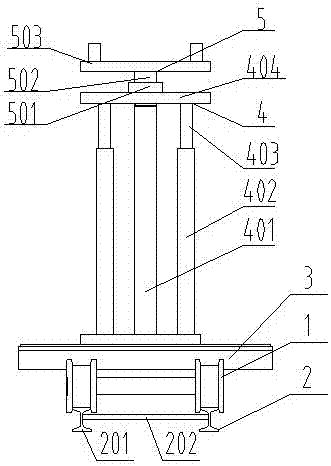

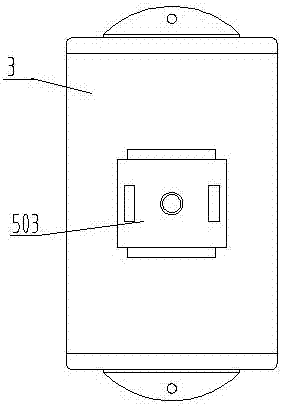

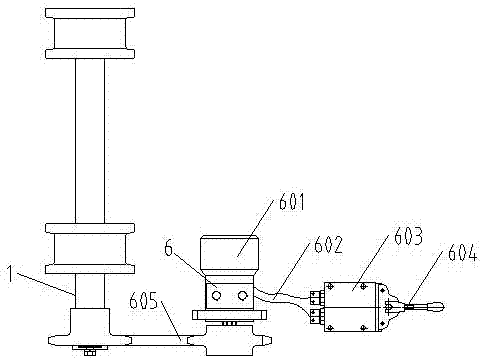

[0020] As shown in the figure, a self-braking frame moving vehicle includes a platform 3 that is slid on the I-shaped steel track 2 through the wheel shaft 1, and the wheel shaft 1 reciprocates along the I-shaped steel track 2 under the drive of the driving mechanism 6. Moving, the platform 3 is provided with a lifting mechanism 4, the lifting mechanism 4 includes a loading plate 404 arranged on the top of the platform 3, a lifting jack 401 arranged between the loading plate 404 and the platform 3, two symmetrically arranged lifting jacks 401 The supporting and guiding cylinders 402 on both si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com