Control method and device applied to air-cooling cold water heat recovery unit

An air-cooled cold water and heat recovery technology, which is applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as secondary evaporation and unit failure to operate normally, improve efficiency and stability, and solve secondary evaporation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The control method applied to the air-cooled cold water heat recovery unit provided by the present invention will be described below with reference to the accompanying drawings.

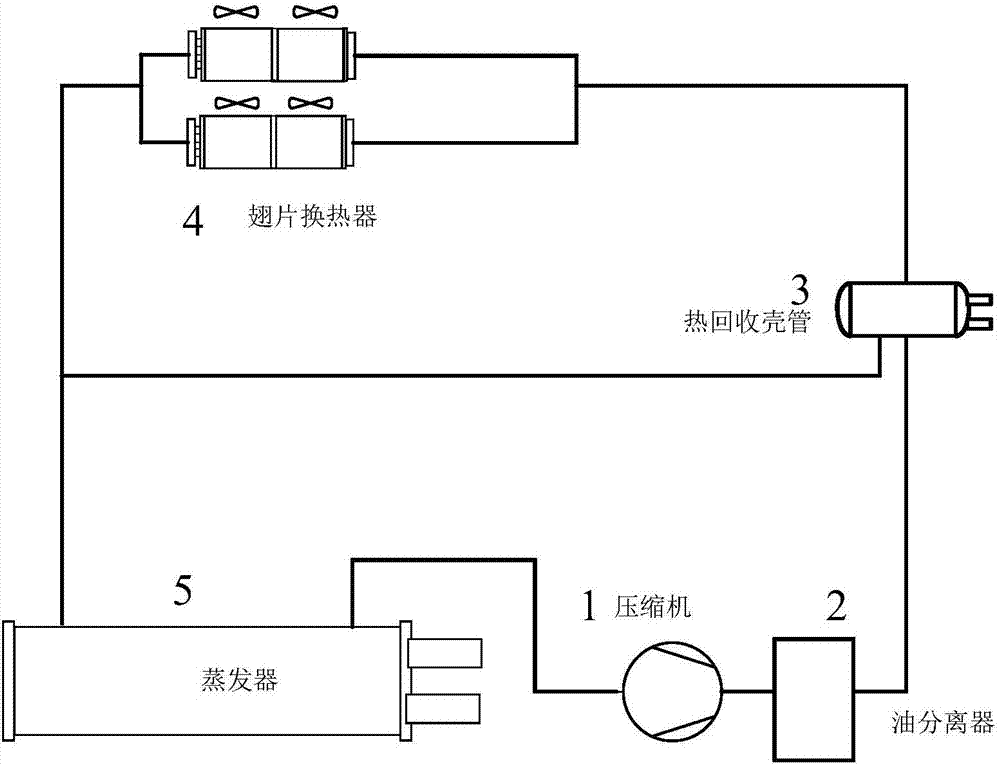

[0025] figure 1 It shows an optional structural diagram of the air-cooled cold water heat recovery unit in the prior art, such as figure 1 As shown, the air-cooled cold water heat recovery unit includes a compressor 1 , an oil separator 2 , a heat recovery shell tube 3 , a condenser 4 (fin heat exchanger) and an evaporator 5 . When the air-cooled cold water heat recovery unit is running, due to the large temperature difference between the refrigerant and the water at the heat recovery shell tube, the heat exchange effect is very good, resulting in the high-temperature and high-pressure refrigerant coming out of the heat recovery shell tube into a medium-temperature high-pressure refrigerant. Refrigerant, and there will be a part of the pressure drop in the process of entering the condenser. I...

Embodiment 2

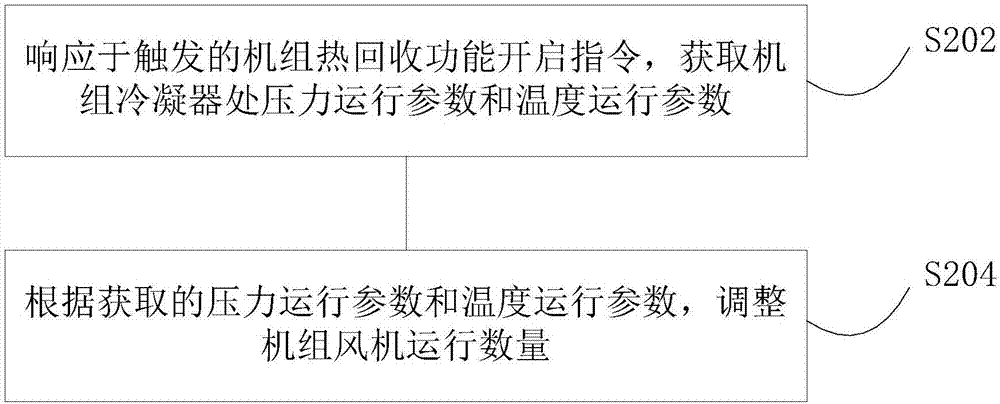

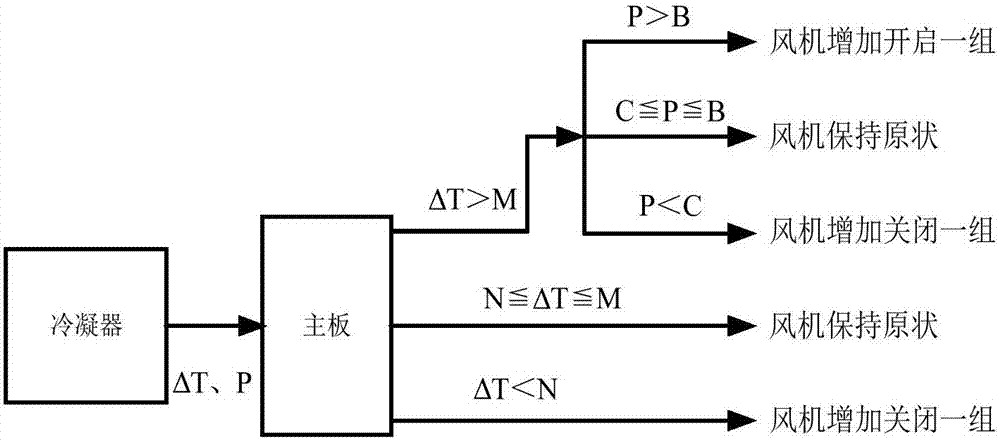

[0044] Based on the control method applied to the air-cooled cold water heat recovery unit provided in the above-mentioned embodiment 1, the optional embodiment 2 of the present invention also provides a control device applied to the air-cooled cold water heat recovery unit, specifically, Figure 4 shows an optional structural block diagram of the device, such as Figure 4 As shown, the device includes: an acquisition unit 42, which is used to acquire the pressure operating parameters and temperature operating parameters at the condenser of the unit in response to the triggered unit heat recovery function start command; an adjustment unit 44, connected to the acquisition unit 42, for The obtained pressure operating parameters and temperature operating parameters are used to adjust the operating number of the fans of the unit.

[0045] Further, the acquisition unit includes: a first acquisition module, used to acquire the ambient temperature at the condenser of the unit; a seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com