Compressor exhaust temperature detection structure and air conditioner device

A temperature detection device, compressor exhaust technology, applied in refrigerators, refrigeration and liquefaction, refrigeration safety arrangements, etc., can solve the problem of inability to effectively detect the temperature of the exhaust gas lacking fluorine in the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

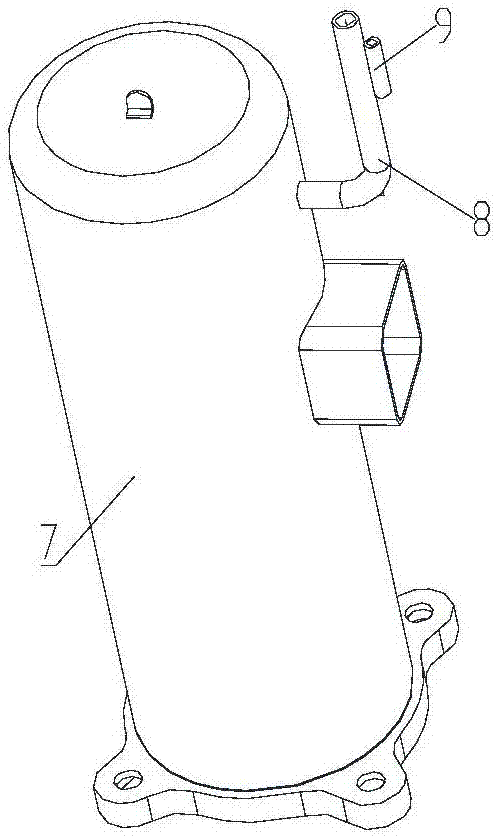

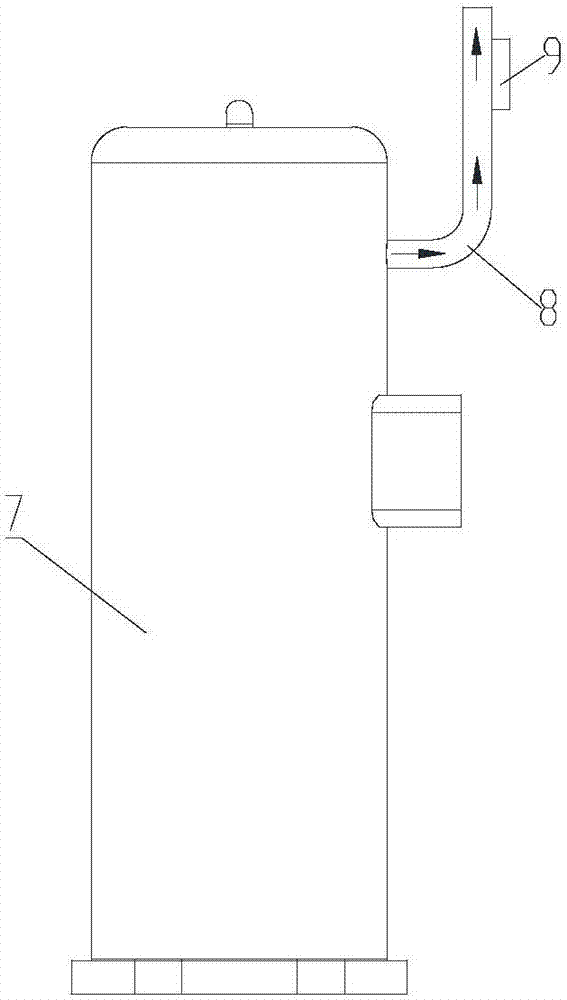

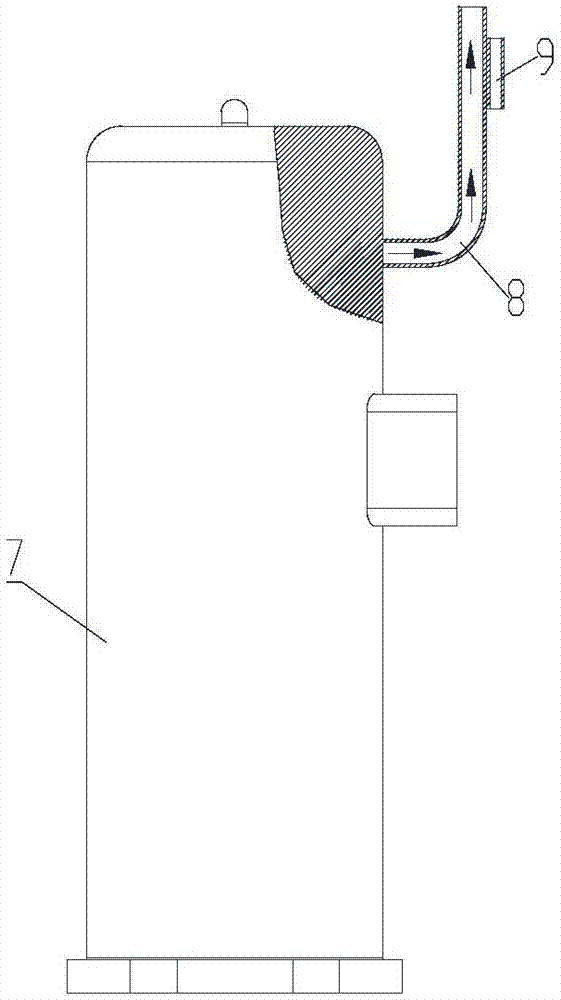

[0027] Figure 1 to Figure 3 Shows the exhaust structure of most air conditioners in the prior art. like Figure 1 to Figure 3 As shown, under normal conditions, the low-temperature and low-pressure gaseous refrigerant is sucked into the compressor, and the high-temperature and high-pressure gaseous refrigerant is discharged through the exhaust port of the compressor, and at the same time enters the exhaust structure of the air conditioner, and then is discharged through the exhaust structure to enter the heat exchange cycle system. Wherein, the exhaust pipe 8 is vertically bent, and the temperature sensing package 9 is installed on the side of the exhaust pipe 8 away from the compressor housing. In order to prevent the exhaust temperature of the compressor from being too high durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com