A temperature sensitive paint

A sensitive and paint technology, applied in the direction of heat-sensitive paint, luminescent paint, polyether paint, etc., can solve the problems of poor thermal conductivity, error, poor thermal conductivity of polymer coating film, etc., to reduce the temperature gradient, improve the response frequency, improve the sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Raw materials: matrix material: polyethylene glycol with a molecular weight of 8000

[0055] Luminescent material: Y 2 o 3 :Eu 3+

[0056] Thermally conductive material: micron-sized aluminum powder, particle size 1-20μm

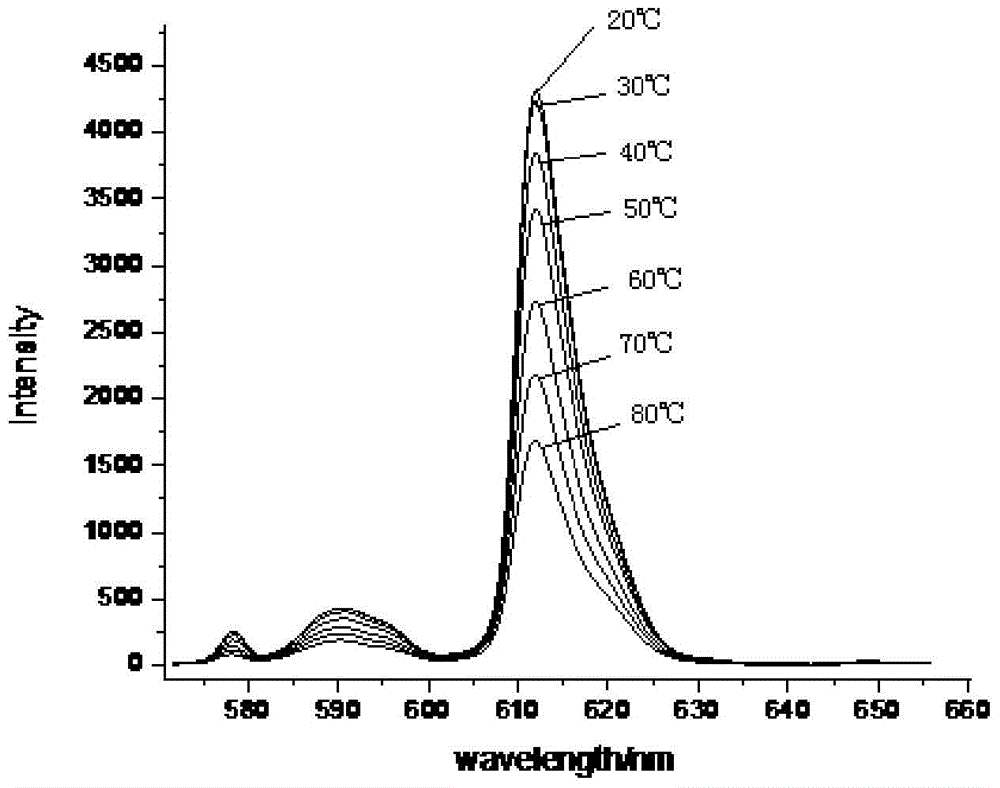

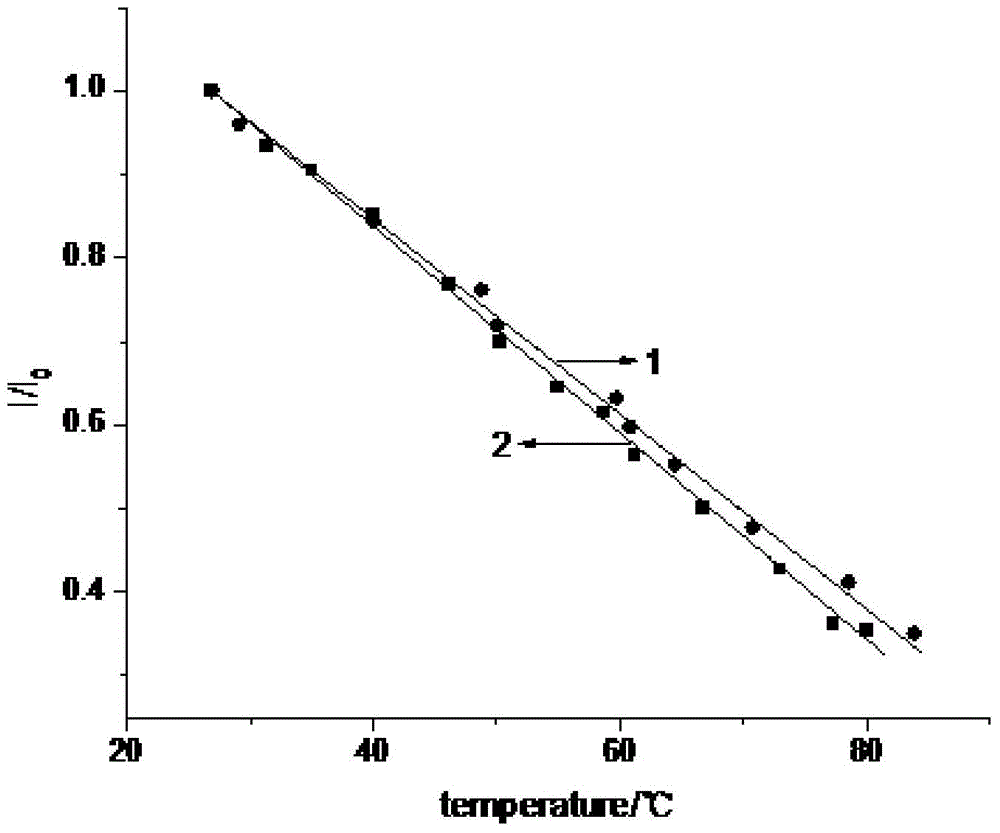

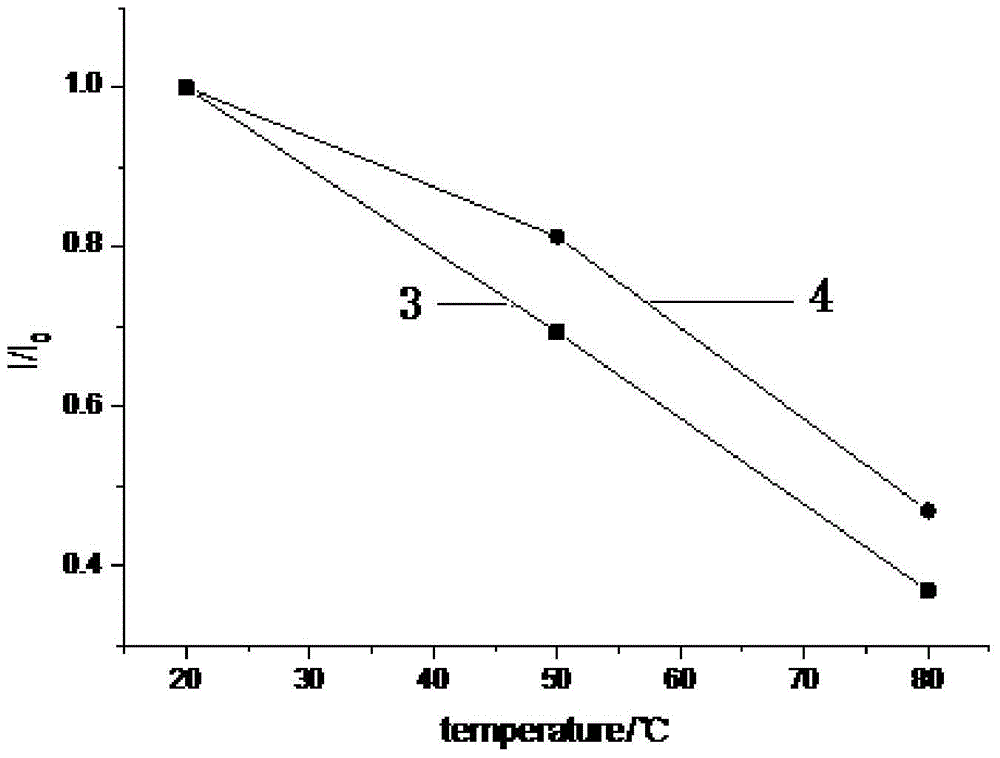

[0058] Take 100g of matrix material, 0.05g of luminescent material, 1.0g of heat-conducting material, and 20.0g of benzene, and stir at a high speed to obtain a temperature-sensitive coating, and cast the coating on the sample to be tested to form a coating film with a thickness of 20 μm. Dry at room temperature for 20 hours, and then dry at a high temperature of 80° C. for 18 hours to remove residual solvent to obtain the temperature-sensitive coating film. The prepared temperature-sensitive coating film has strong fluorescence intensity in the wavelength of 610-620nm when excited by the excitation light with the excitation wavelength of 365nm at 0-80°C. The temperature sensitive material is used for the measurement of...

Embodiment 2

[0060] Raw materials: matrix material: polyethylene glycol with a molecular weight of 20,000

[0061] Luminescent material: Ba 2 ZnS 3 :Mn 2+

[0062] Thermally conductive material: micron-sized aluminum powder, particle size 40-100μm

[0064] Take 100g of matrix material, 5.0g of luminescent material, 80g of heat-conducting material, and 300g of toluene, and stir fully at a high speed to obtain a temperature-sensitive coating, and apply or cast the coating on the sample to be tested to form a coating film with a thickness of 80 μm. Dry at room temperature for 50 hours, and then dry at a high temperature of 110° C. for 30 hours to remove residual solvent to obtain the temperature-sensitive coating film. The prepared temperature-sensitive coating film has strong fluorescence intensity in the wavelength of 600-625nm when excited by the excitation light with the excitation wavelength of 365nm at 0-80°C. The temperature sensitive material is used fo...

Embodiment 3

[0066] Raw materials: matrix material: polyethylene glycol with a molecular weight of 18000

[0067] Luminescent material: trifluoroacetylated thienoyl europium

[0068] Thermally conductive material: micron-sized aluminum powder, particle size 20-50μm

[0070] Take 100g of matrix material, 2.1g of luminescent material, 20.0g of micron-sized aluminum powder, and 150g of xylene, and stir fully at high speed to obtain a temperature-sensitive coating, and apply or cast the coating on the sample to be tested to a thickness of 100 μm. The coating film was dried at room temperature for 35 hours, and then dried at a high temperature of 140° C. for 19 hours to remove residual solvent to obtain the temperature-sensitive coating film. The prepared temperature-sensitive coating film has strong fluorescence intensity in the wavelength of 610-625nm when excited by the excitation light with the excitation wavelength of 365nm at 0-80°C. The temperature sensitive m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com