Method and device for rapid melting of slag material to form liquid film with uniform temperature

A liquid film, rapid technology, applied in the melting and detection of steelmaking refining slag, metallurgical slag materials, melting and detection of mold slag and other slag materials, blast furnace slag, and can solve the problem of inability to correctly transfer the molten liquid slag structure Information and other issues to achieve the effect of preventing heat loss, broad prospects, and prolonging the life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with specific embodiments.

[0033] The method for rapidly melting slag materials to form a liquid film with uniform temperature is characterized in that it comprises the following steps:

[0034] 1) Mix the powder of slag material with alcohol evenly to form a paste-like slag as a sample;

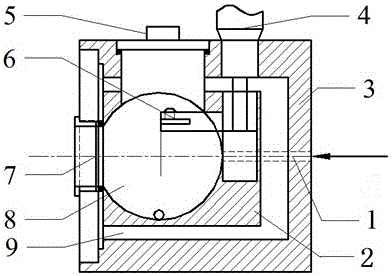

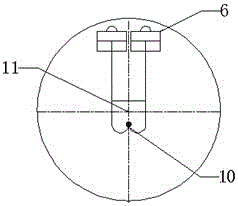

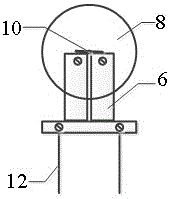

[0035] 2) Heat the sample through a closed heating device. The heating device is a heater composed of a thermocouple. The head of the thermocouple is folded into a W shape. Take the sample and place it in the W head area of the thermocouple, and close the heating device;

[0036] 3) Fix the two ends of the thermocouple on the two terminals of the electrode seat respectively, and then connect the two terminals to the temperature control system through cables;

[0037] 4) Start the temperature control system to heat up the thermocouple, so that the sample absorbs heat energy, and finally forms a molten l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com