High-strength bolt connecting gusset plate compression detection method

An ultrasonic echo, high-strength bolt technology, applied in the direction of measuring force, measuring device, force/torque/work measuring instrument, etc., can solve the problem of inaccurate state of gusset plate, and achieve satisfactory detection speed, high application value, and high accuracy. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

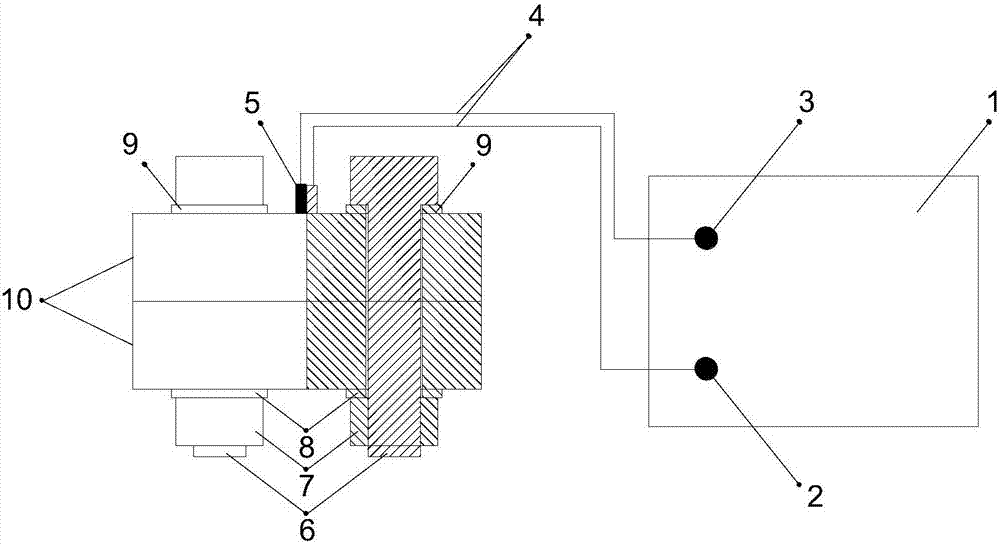

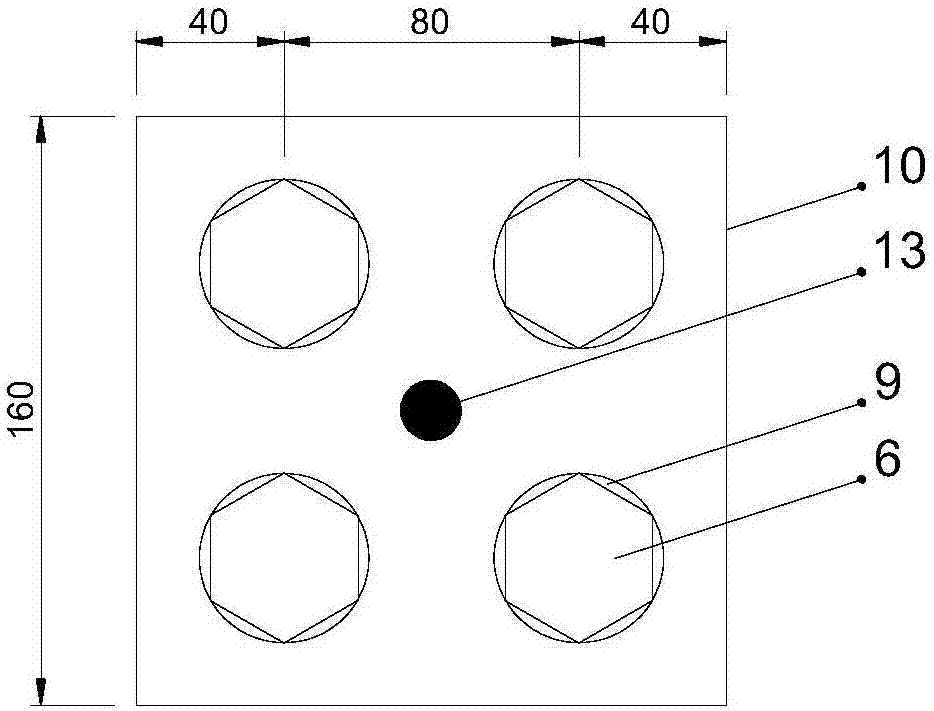

[0035] The thickness of splicing plate 10 is 40mm, the surface is airless sprayed with 160μm inorganic zinc-rich paint, and four high-strength bolt holes are reserved; the high-strength bolts are S10.9 grade M24 large hexagon head bolts, E=1GPa, μ=0.38, D=1.53, G=1e-10.

[0036] According to different high-strength bolt screwing sequences, two sets of test pieces are completed twice to complete the field test. Number the times of ultrasonic testing from 1 to 5 during the testing process. The four high-strength bolts are numbered from 1 to 4 in the clockwise direction, and screwed to 230KN in sequence. The tension sequence of the high-strength bolts during the experiment of each group of specimens is shown in Table 1.

[0037] Table 1 Tightening sequence of high-strength bolts during the experiment (unit: KN)

[0038]

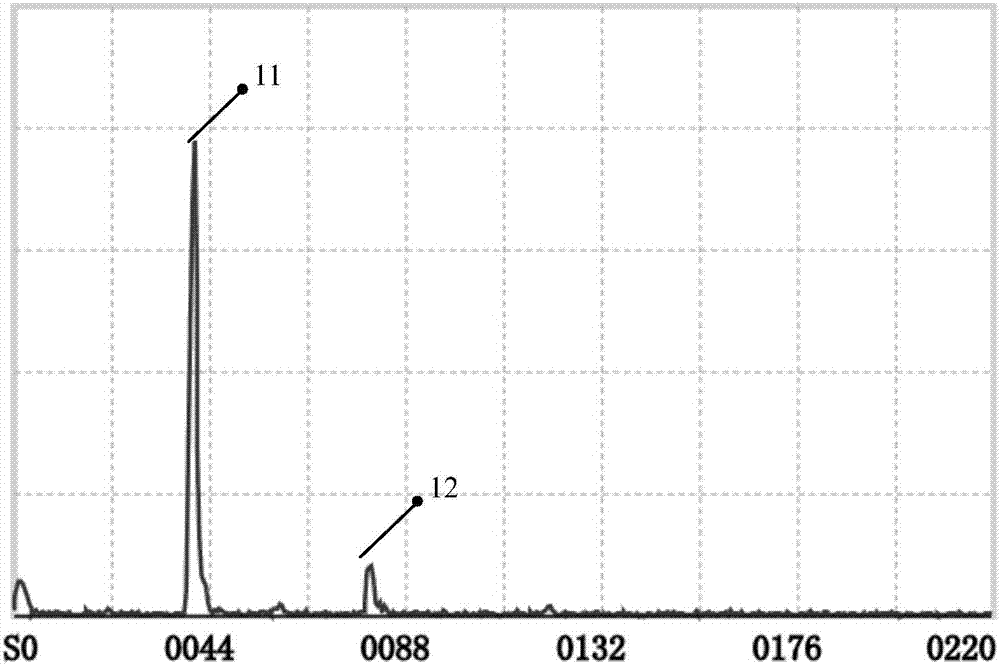

[0039] Read the ultrasonic echo data in the non-destructive testing flaw detector, sequentially extract the sound intensity values of the two echoes in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com