Wire harness test device

A technology of testing devices and wiring harnesses, applied in the direction of fault locations, etc., can solve problems such as failure to be discovered in time, slow detection time, cumbersome detection steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

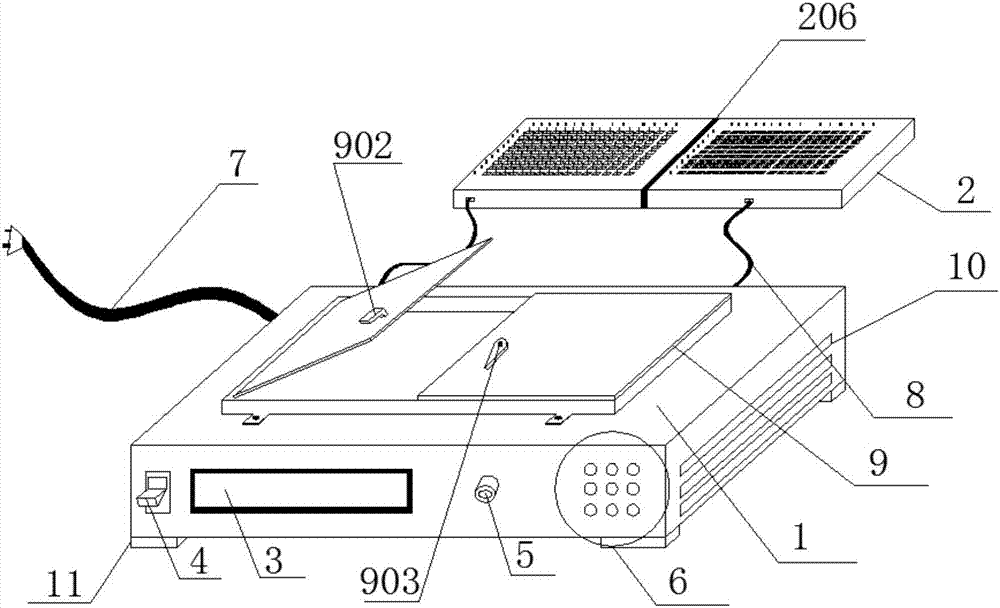

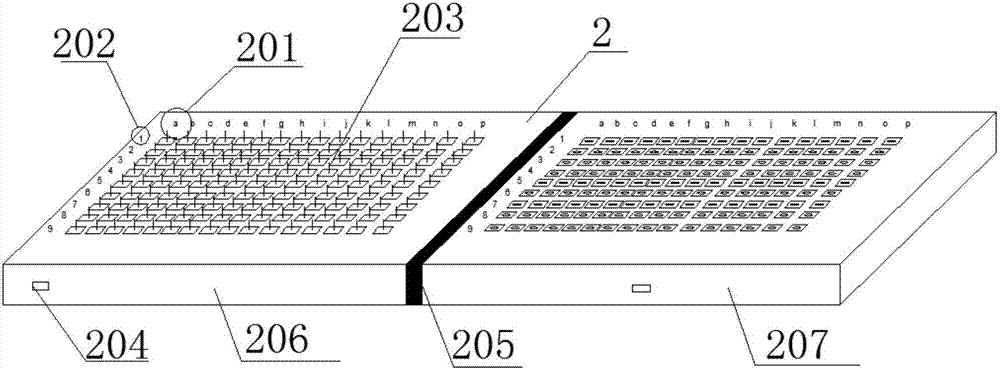

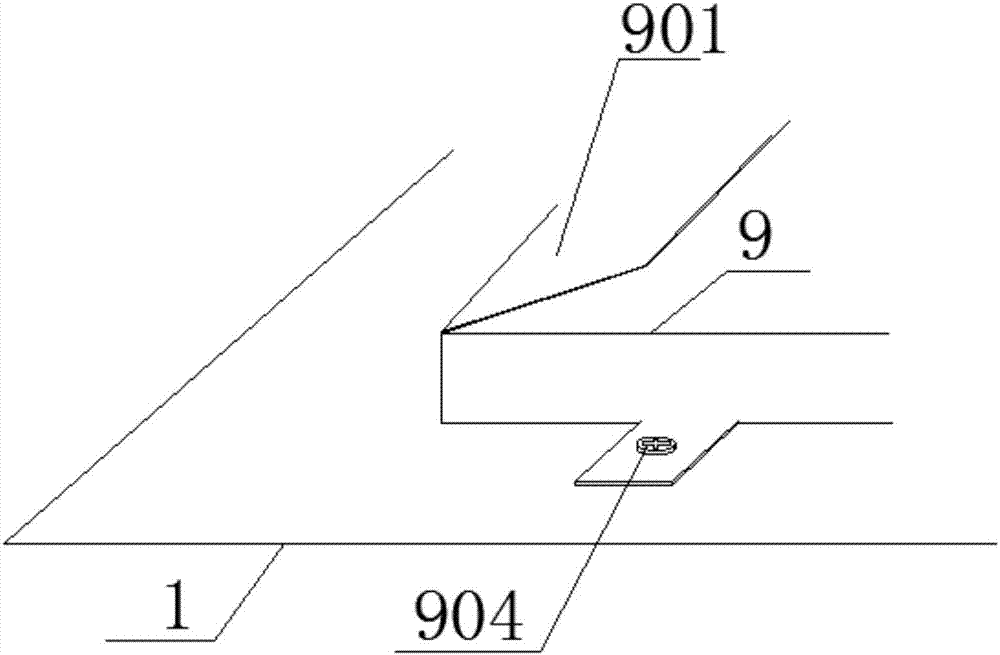

[0020] figure 1 , figure 2 , image 3 and Figure 4 The specific embodiment of the present invention is shown: a wire harness testing device, including a tester 1 and a test board 2. The tester 1 is provided with a display screen 3, a switch 4, a voltage adjustment knob 5 and a keyboard 6. The test board 2 and the tester 1 are plugged with detachable wires 8, the tester 1 is externally connected with a three-phase electric plug 7, the tester 1 is provided with a test board box 9, and the tester 1 is connected to the tester 1 Detachable connection, the test board 2 includes a left test board 206 and a right test board 207, the left test board 206 and the right test board 207 are detachably connected, and the left test board 206 and the right test board 207 are all provided with There are test contacts 203 arranged in matrix on the left test board 206 and the right test board 207 .

[0021] In this embodiment, the test board box 9 is provided with two symmetrical box covers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com