Real-time monitoring equipment operation and maintenance management system of engine test bed

A technology of operation and maintenance management and real-time monitoring, which is applied in the direction of engine testing, general control system, control/regulation system, etc., can solve the problems of low degree of automation, poor system scalability, and low accuracy of manual recording, so as to save enterprise expenses, Improved noise immunity and shortened development time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

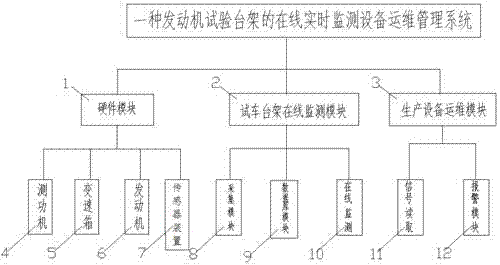

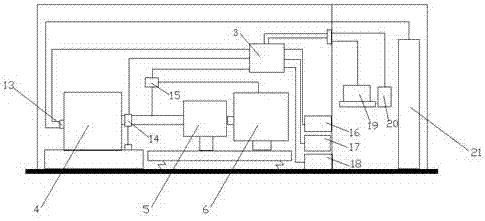

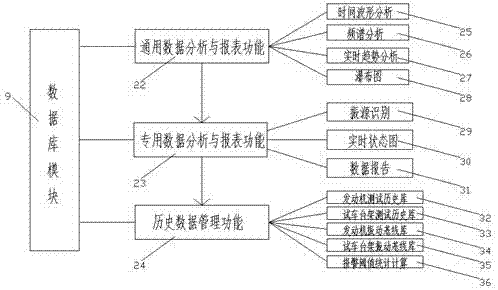

[0026] An online real-time monitoring equipment operation and maintenance management system of an engine test bench, including a hardware module 1, a test bench online monitoring module 2, a Web-based production equipment operation and maintenance management module 3, and the hardware module 1 and Web-based The production equipment operation and maintenance management module 3 is connected to the test bench online monitoring module 2, and the Web-based production equipment operation and maintenance management module 3 is connected to the test bench online monitoring module 2,

[0027] Described hardware module 1 is used to realize the acquisition of system input signal, and described test vehicle stand online monitoring module 2, the vibration value of each measuring point measured by analyzing hardware module 1 and the rotating speed value of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com