A wire-laying method of an automatic wire-laying system for unmanned aerial vehicle based on visual recognition

A visual recognition and unmanned aerial vehicle technology, applied in scene recognition, control/adjustment system, character and pattern recognition, etc., can solve the problems of time waste, manipulation operation interference, low efficiency, etc., to overcome the limitations of terrain factors, shorten the Effects of improving work time and stringing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below will combine specific embodiment and appended Figure 1-5 , clearly and completely describe the technical solutions in the embodiments of the present invention, obviously, the described embodiments are only some preferred embodiments of the present invention, not all the embodiments. Those skilled in the art can make similar modifications without departing from the connotation of the present invention, so the present invention is not limited by the specific embodiments disclosed below.

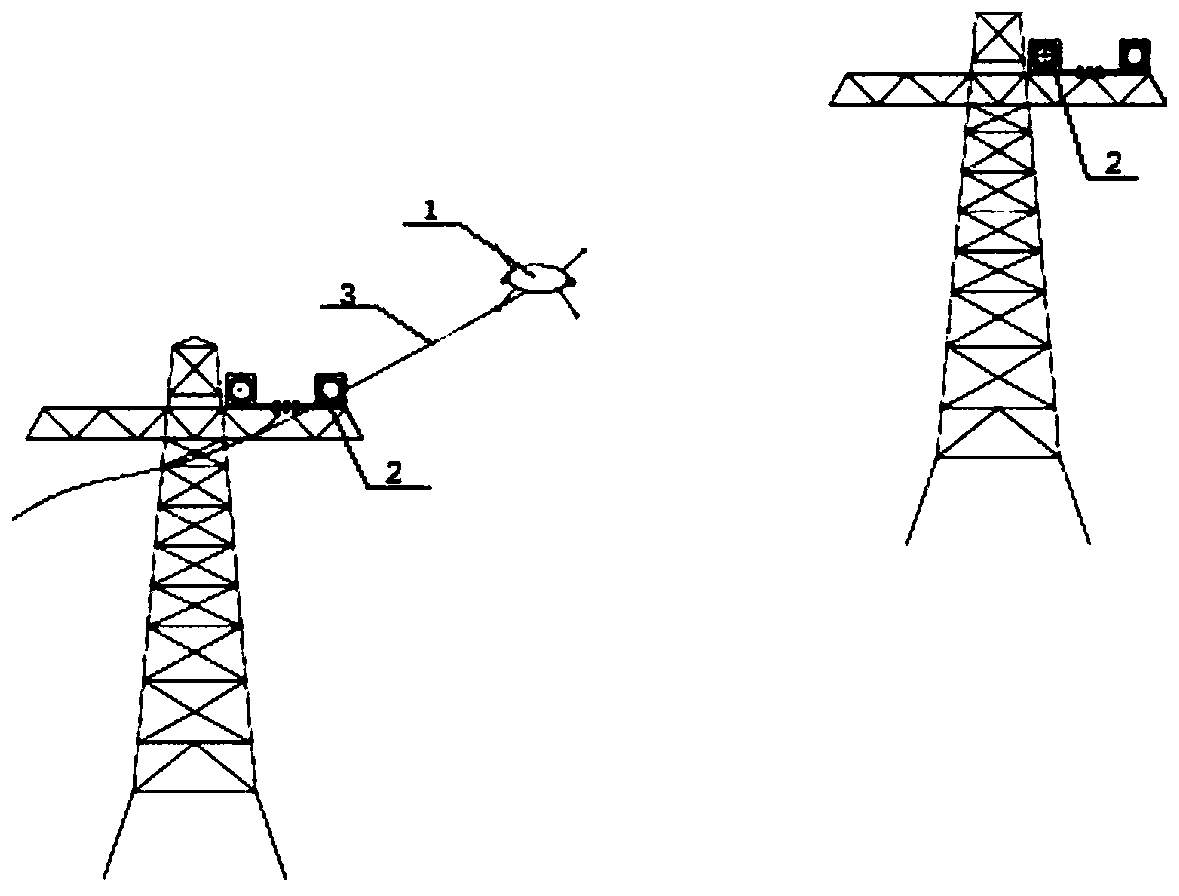

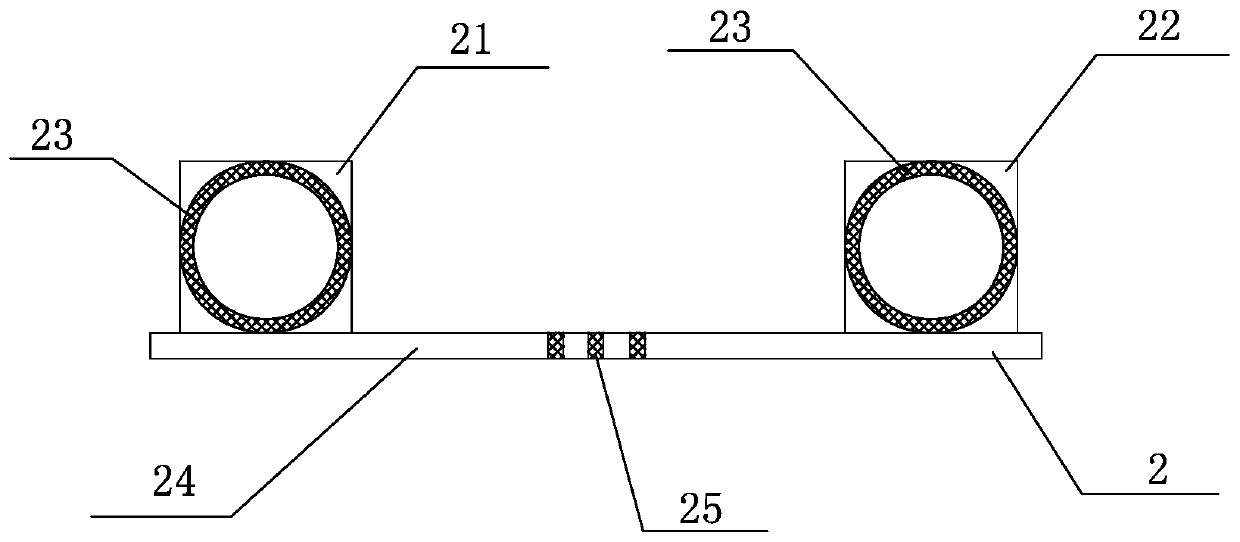

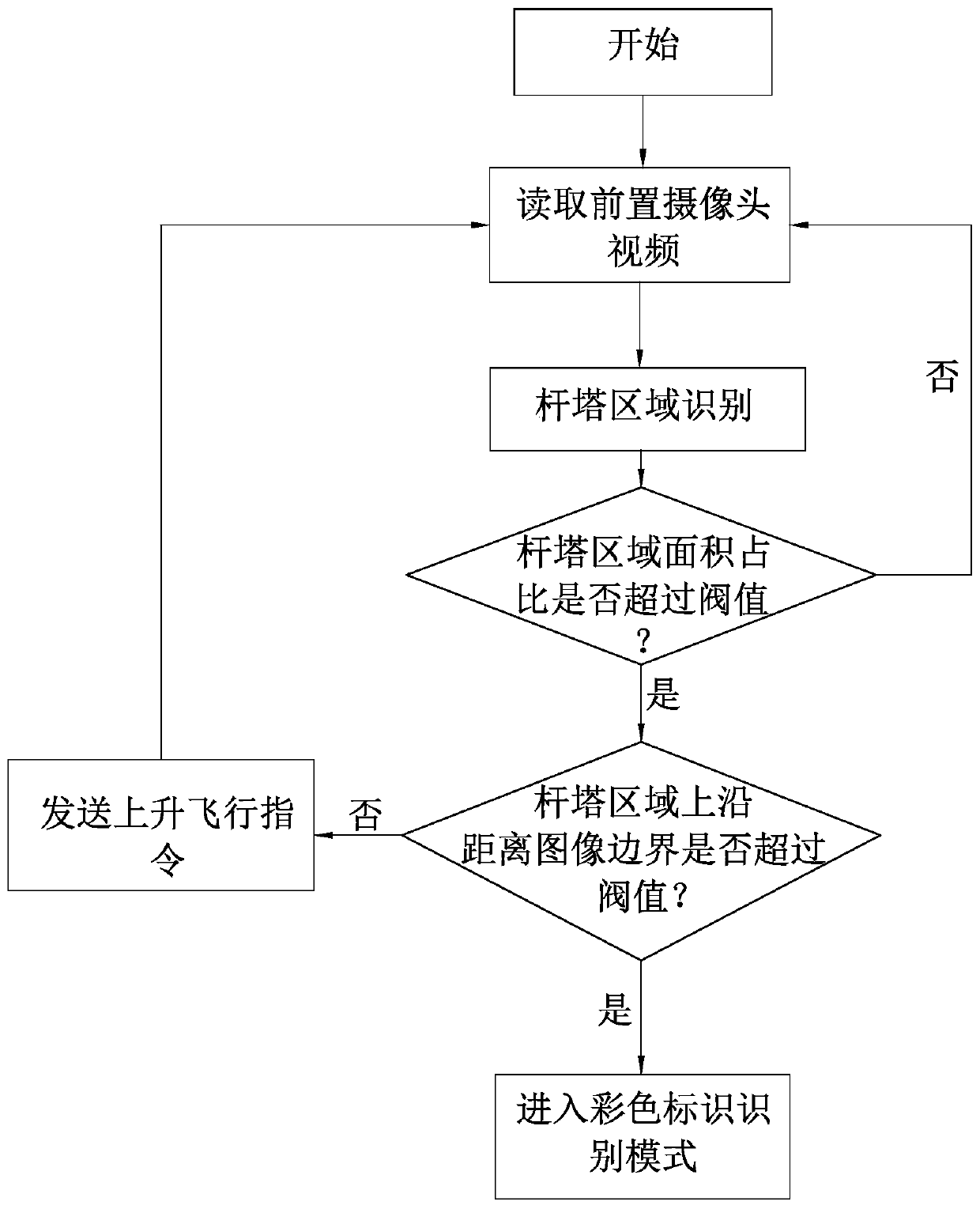

[0034] The invention provides a visual recognition-based automatic pay-off system for unmanned aerial vehicles (such as figure 1 Shown), including unmanned aerial vehicle 1, visual collection system and fixed crossbar marking device 2, described unmanned aerial vehicle 1 includes a control module, and described visual collection system includes front camera, rear camera and visual processing module, The front camera and the rear camera are respectively arranged at the front and b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com